An ultra-high-precision plane mirror full-aperture intermediate-frequency surface shape measurement device and method

A technology of measuring devices and plane mirrors, which is applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effects of eliminating position errors, improving splicing measurement accuracy, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further illustrate the features of the present invention, the following description is given in conjunction with specific embodiments and the accompanying drawings.

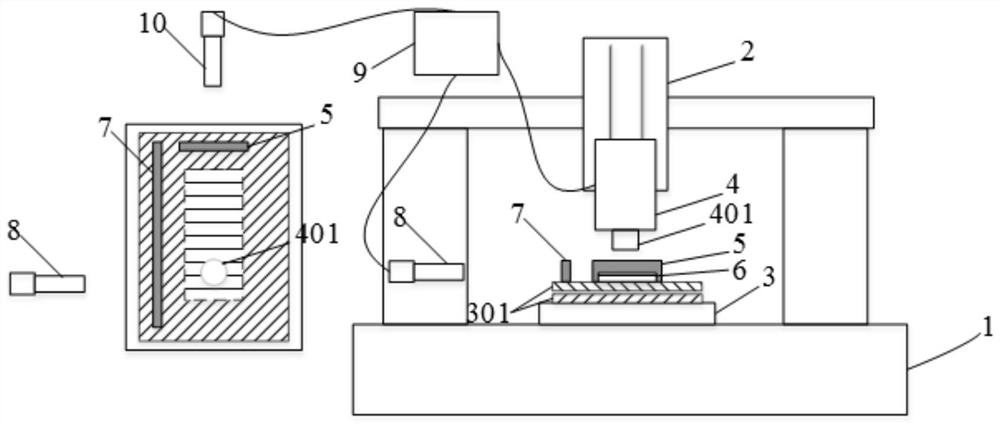

[0058] figure 1 Shown is the ultra-high-precision plane mirror full-aperture intermediate-frequency surface measurement device in the present invention, including: a marble base 1, a lifting device 2, an axial displacement stage 3, a tilt adjustment stage 301, a white light interferometer 4, a microscope objective lens 401, a short Standard plane mirror 5, ultra-high-precision plane mirror 6, long standard plane mirror 7, first autocollimator 8, computer system 9 and second autocollimator 10; wherein, the white light interferometer 4 is installed on the lifting device 2, and is connected with The axial displacement stage 3 is fixed on the marble base 1 to isolate errors caused by environmental factors; the tilt adjustment stage 301 is installed on the axial displacement stage 3 to realize the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com