Anti-loose fastener and cushion block

A technology for loosening fasteners and pads, applied to threaded fasteners, locking fasteners, connecting components, etc., which can solve the problems of increased production costs of fasteners, failure of fastened connections, and increased structure and volume of fasteners And other problems, to achieve the effect of guaranteeing the service life, guaranteeing the anti-loose performance and improving the anti-loose performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

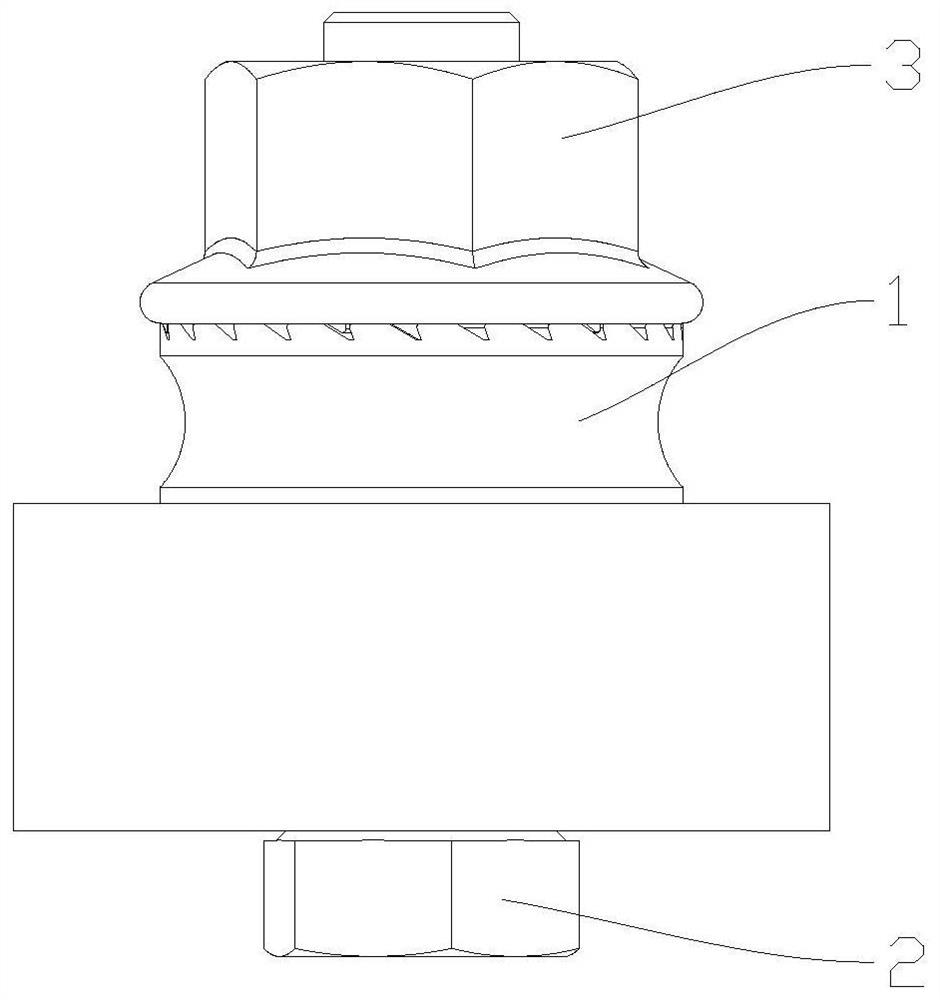

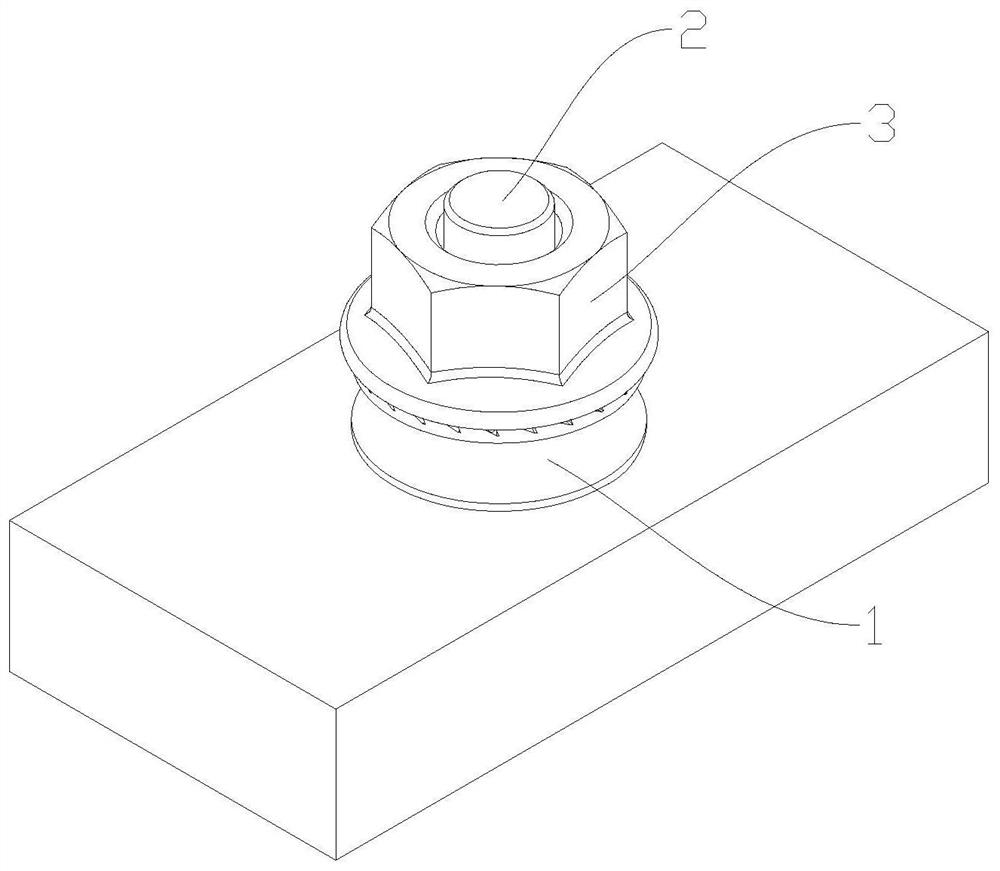

[0058] Embodiment 1: In this embodiment, if Figure 5 and Figure 6 As shown, the screwed body is a nut 3, and the nut 3 includes a nut body 31 and a nut base 32 arranged at one end of the nut body 31, the outer diameter of the nut base 32 is larger than the nut body 31, The surface of the nut base 32 in contact with the spacer 1 is the abutting end surface. In practical applications, a certain method is adopted, such as fixing the bolt 2 relative to the workpiece with a screwdriver, the spacer 1 and the nut 3 are set on the other end of the bolt 2 in turn, and the nut 3 is screwed to perform pre-tightening. After pre-tightening, the spacer 1 1 is squeezed and deformed between the nut 3 and the workpiece, the rebound force of the block 1 acts on the abutting end surface of the nut 3, and the nut rotates and self-retracts to overcome the huge sliding friction force given by the block, so there is no strong external force interference Under this condition, the nut 3 is difficu...

Embodiment approach 2

[0059] Embodiment 2: In this embodiment, the screw-in body is a bolt 2 , and the side where the head of the bolt 2 is in contact with the pad 1 is the abutting end surface. In practical applications, a certain method is adopted, such as fixing the nut 3 relative to the workpiece by a wrench, the pad 1 is sleeved on one end of the head of the bolt 2, and the bolt 2 is screwed in for pre-tightening. After pre-tightening, the pad 1 is in the The workpiece and the head of the bolt 2 are squeezed and deformed, and the resilience of the pad 1 acts on the abutting end surface of the head of the bolt 2. The bolt needs to overcome the huge sliding friction force given by the pad and the pad The clamping force given by the annular side portion 12 of the bolt 1 makes it difficult for the bolt 2 to self-retreat without the interference of a strong external force, which ensures the anti-loosening performance of the anti-loosening fastener.

Embodiment approach

[0060] As a preferred embodiment of the present invention, an adhesive layer is provided on the bottom surface of the spacer 1 . During installation, the adhesive layer on the bottom surface of the pad 1 adheres to the workpiece, which can realize the positioning of the pad 1 and prevent the pad 1 from shifting or rotating with the swivel body when the screw body is rotated, thereby affecting the anti-loosening fastener. Installation can also prevent the anti-loosening fasteners from being pre-tightened and then rotate synchronously with the block 1 to cause self-retreat, further improving the anti-loosening performance of the anti-loosening fasteners.

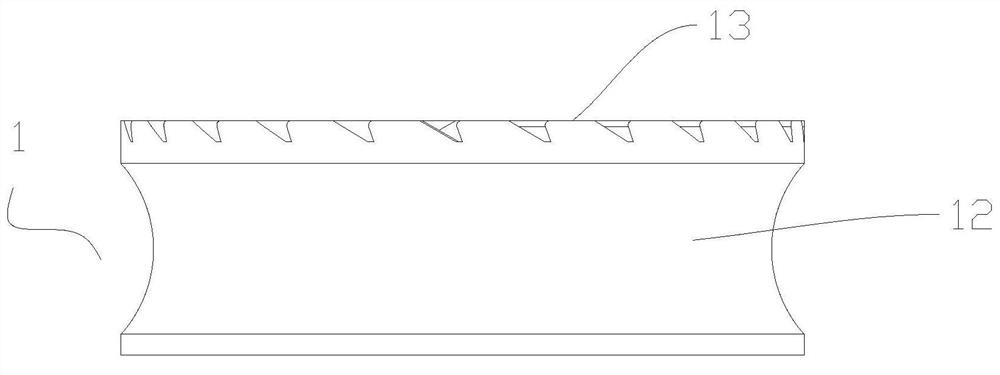

[0061]As a preferred embodiment of the present invention, the indentation depth of the outer wall of the annular side portion 12 to the inner wall of the annular side portion 12 is selected from 30%-50% of the thickness of the annular side portion 12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com