Microbial fermentation tank with air distributor for increasing oxygen capacity

An air distributor, microbial fermentation technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, enzymology/microbiology device, etc. The problem of low qualified rate of fermented products can save workers' time and improve the qualified rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

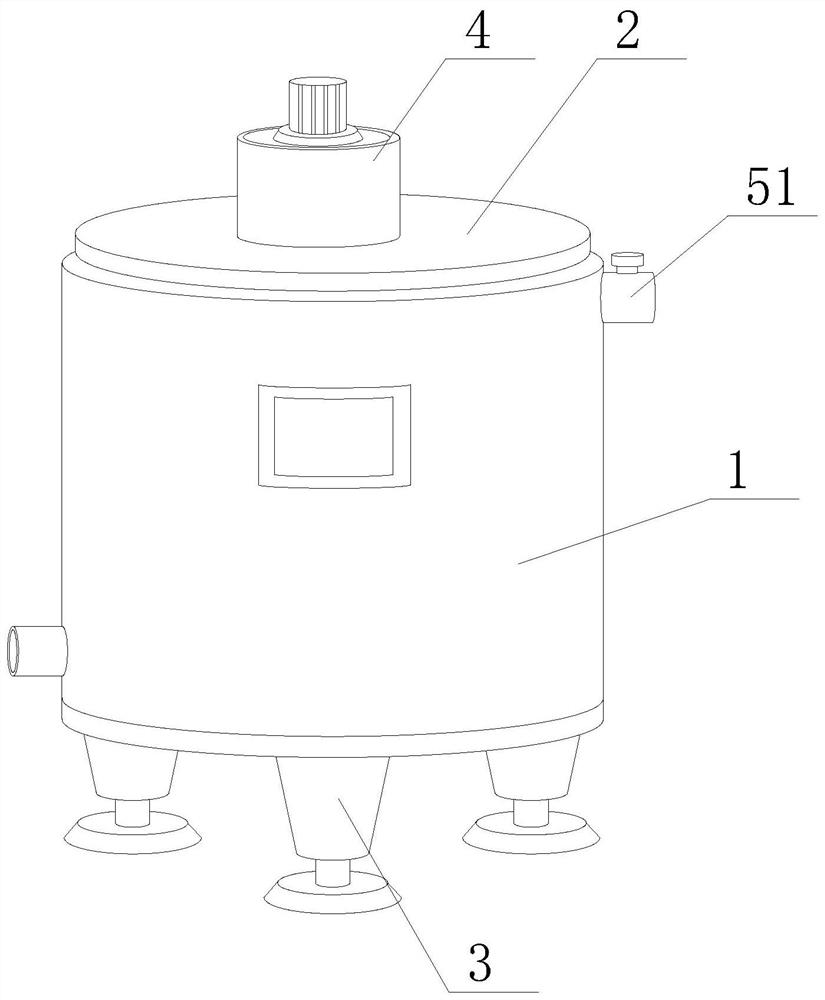

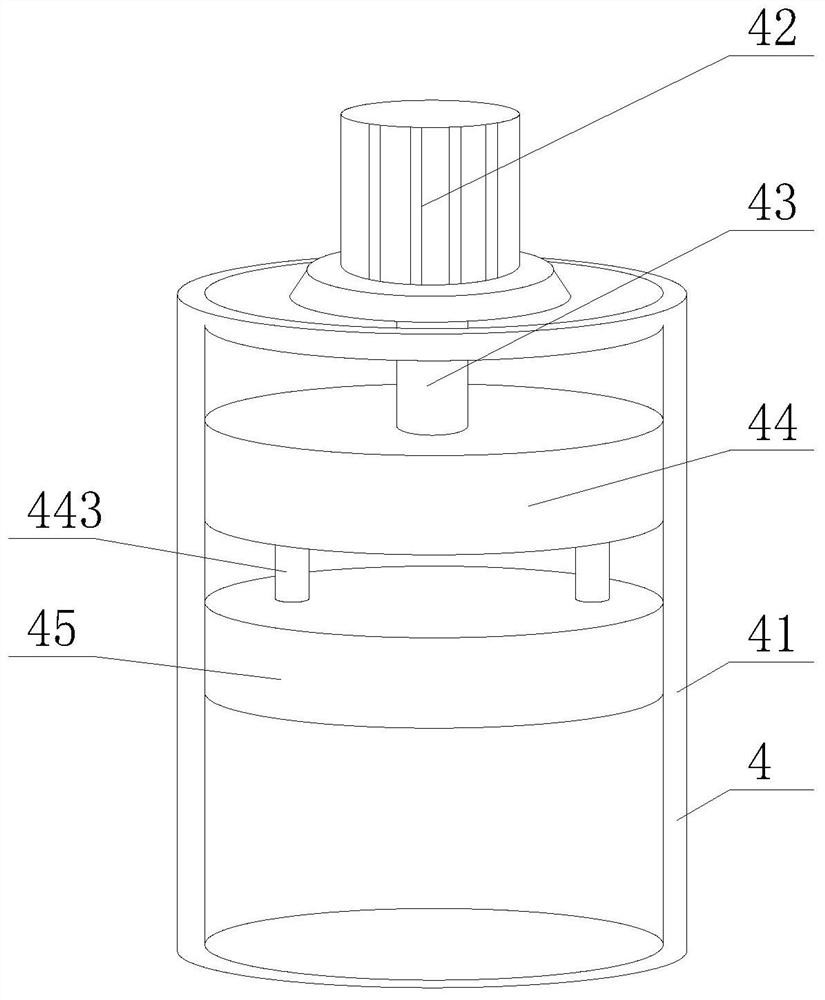

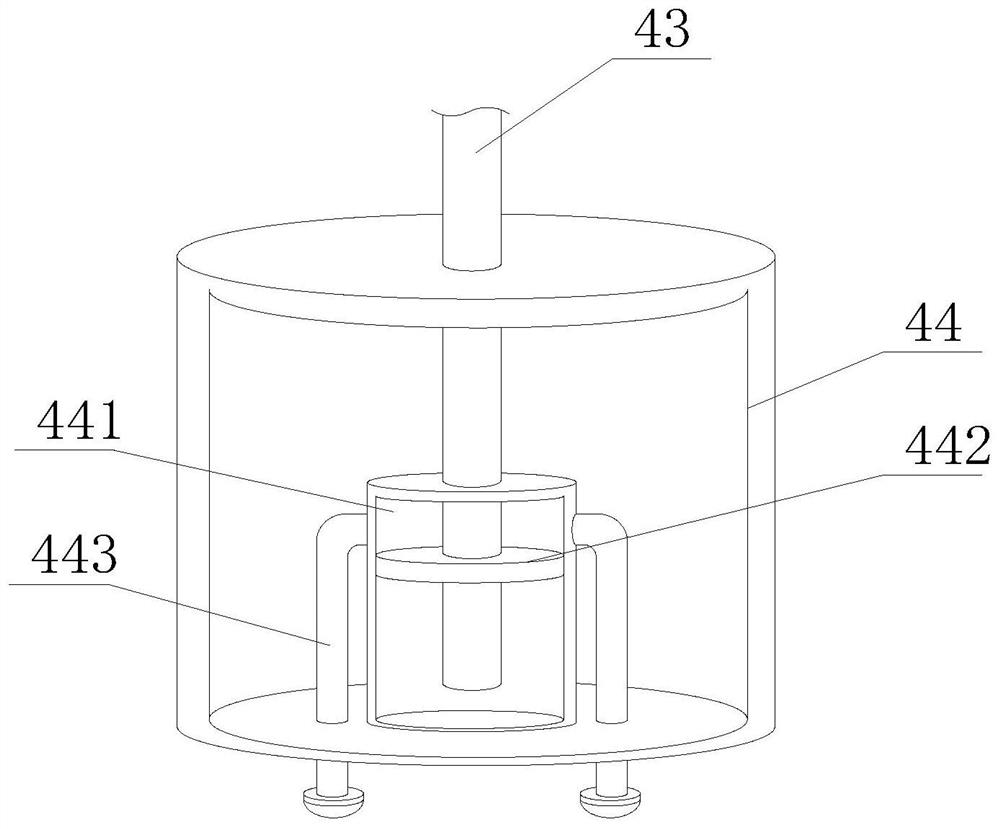

[0049] Such as Figure 1-10As shown, the present invention provides a microbial fermenter with an air distributor to increase the oxygen capacity, comprising a fermenter body 1, a cover plate 2 and support legs 3, the top of the fermenter body 1 is movably equipped with a cover plate 2, fermented The bottom of the tank body 1 is fixedly connected with support legs 3, the top of the cover plate 2 is provided with an exhaust device 4, the top of the inner cavity of the fermenter body 1 is provided with an air suction device 5, and the bottom of the inner cavity of the fermenter body 1 is fixed. The stirring device 6 is connected, the exhaust device 4 includes an exhaust pipe 41, the inner cavity of the exhaust pipe 41 is fixedly sleeved with an air distributor body 45, and the inner cavity of the exhaust pipe 41 is fixedly sleeved with a fixed box 44, fixed The bottom of the inner cavity of the box 44 is fixedly connected with a clean water tank 441, the inner cavity of the clea...

Embodiment 2

[0052] Such as Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the suction device 5 includes an elastic hose 51, and the inner cavity of the elastic hose 51 is fixedly sleeved with a baffle plate 511, and the baffle plate The inner cavity of 511 is provided with a through hole 512, the inner cavity of the through hole 512 is fixedly sleeved with a barrier cotton 513, one side of the top of the elastic hose 51 is fixedly connected with a cylinder 53, and the top of the cylinder 53 is fixedly connected with a support plate 54 to support One side of the plate 54 is fixedly connected to the top side of the inner cavity of the fermenter body 1, and a leakage hole is opened on one side of the bottom of the elastic hose 51, and one end of the elastic hose 51 extends to the outside of the fermenter body 1, and the elastic hose 51 The other side of the top is fixedly connected with a suction pump 52 .

[0053] In th...

Embodiment 3

[0055] Such as Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the stirring device 6 includes a stirring plate 62, the outer wall of the stirring plate 62 is movably connected with a baffle 65, and one side of the baffle 65 is fixed A vibrator 67 is connected, and a spring 66 is fixedly connected to the other side of the baffle plate 65. One end of the spring 66 is fixedly connected to the surface of the stirring plate 62. The bottom of the inner cavity of the fermenter body 1 is fixedly connected to a fixed column 61, and the fixed column 61 The number is two, a straight rod 63 is flexibly connected between the two fixed columns 61, the outer wall of the straight rod 63 is fixedly sleeved in the inner cavity of the stirring plate 62, and the front of the fixed column 61 is fixedly connected with a motor 64, and the output of the motor 64 The end is fixedly connected to one end of the straight rod 63.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com