Probe mechanism and variable-temperature vacuum probe platform

A probe and vacuum technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem that the probe is easy to scratch the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

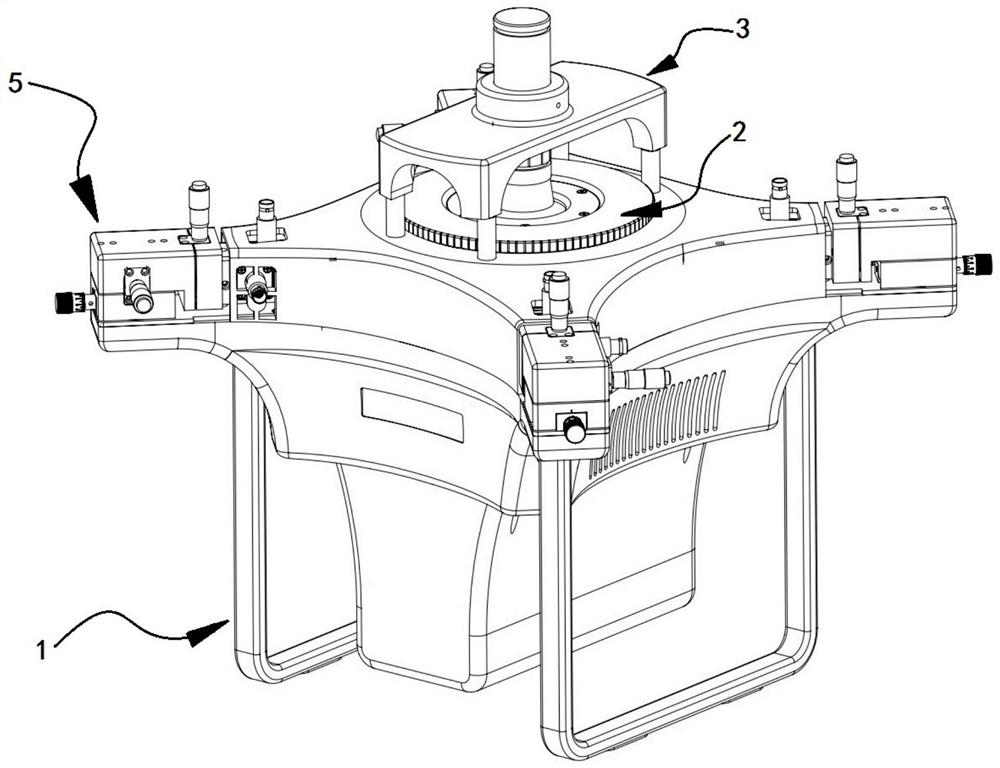

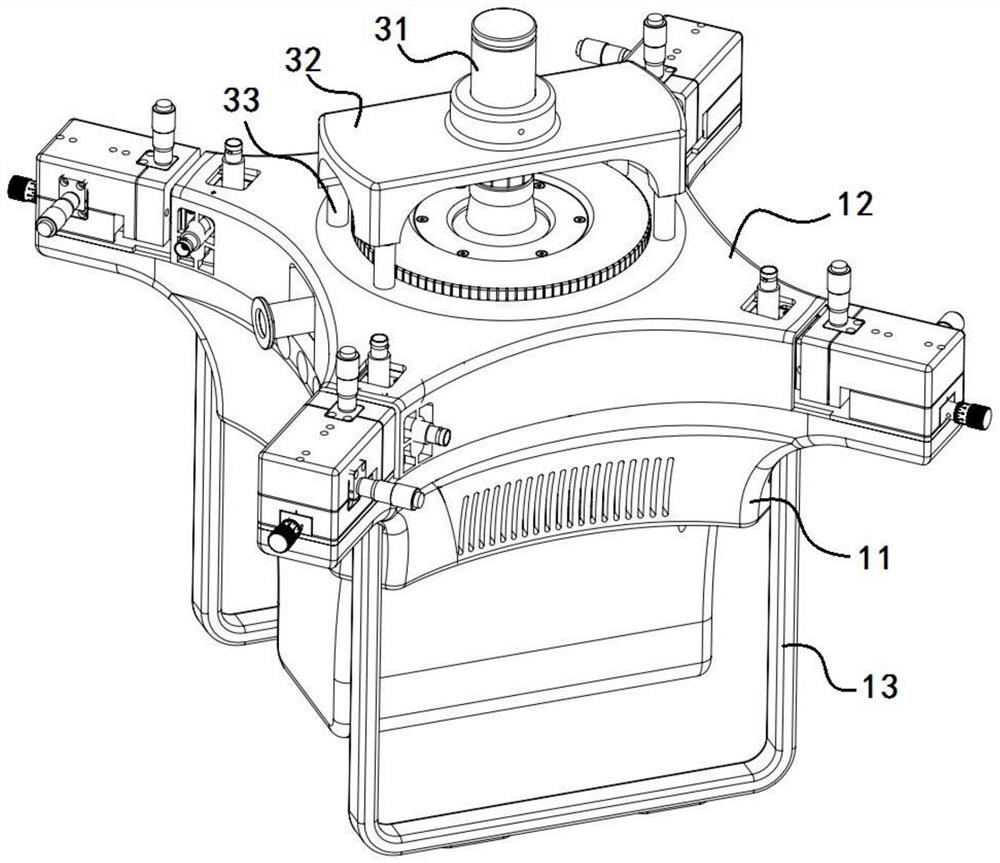

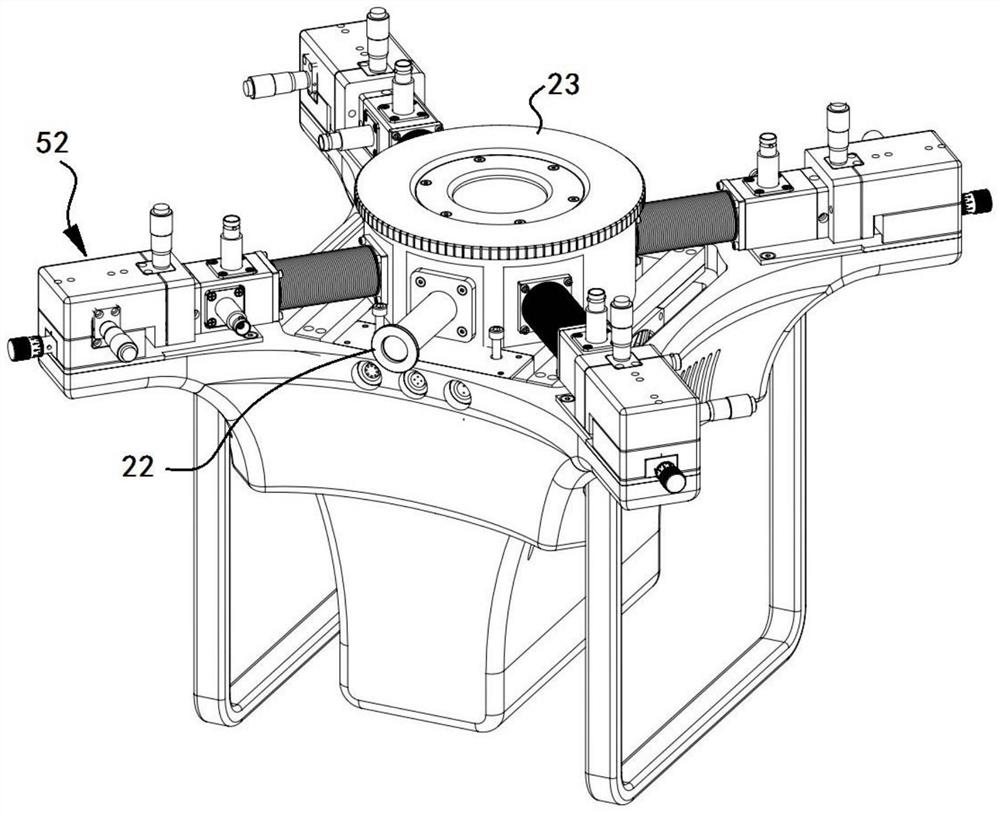

[0034] The invention provides a variable temperature vacuum probe platform, such as figure 1 and figure 2 As shown, it includes a fixing mechanism 1, a vacuum mechanism 2, a microscope mechanism 3, a sample supporting mechanism 4, a plurality of probe mechanisms 5, and a heating and cooling mechanism 6. The fixing mechanism 1 includes a first housing 11, a second housing 12, two A U-shaped bracket 13, the interior of the first housing 11 is hollow and the top is open, the interior of the second housing 12 is hollow and the bottom is open, the top of the second housing 12 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com