A kind of spare tire support assembly and automobile

A technology of bracket assembly and body, applied in the field of auto parts, can solve the problems of laborious replacement, high quality, heavy tires, etc., and achieve the effect of avoiding shaking and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

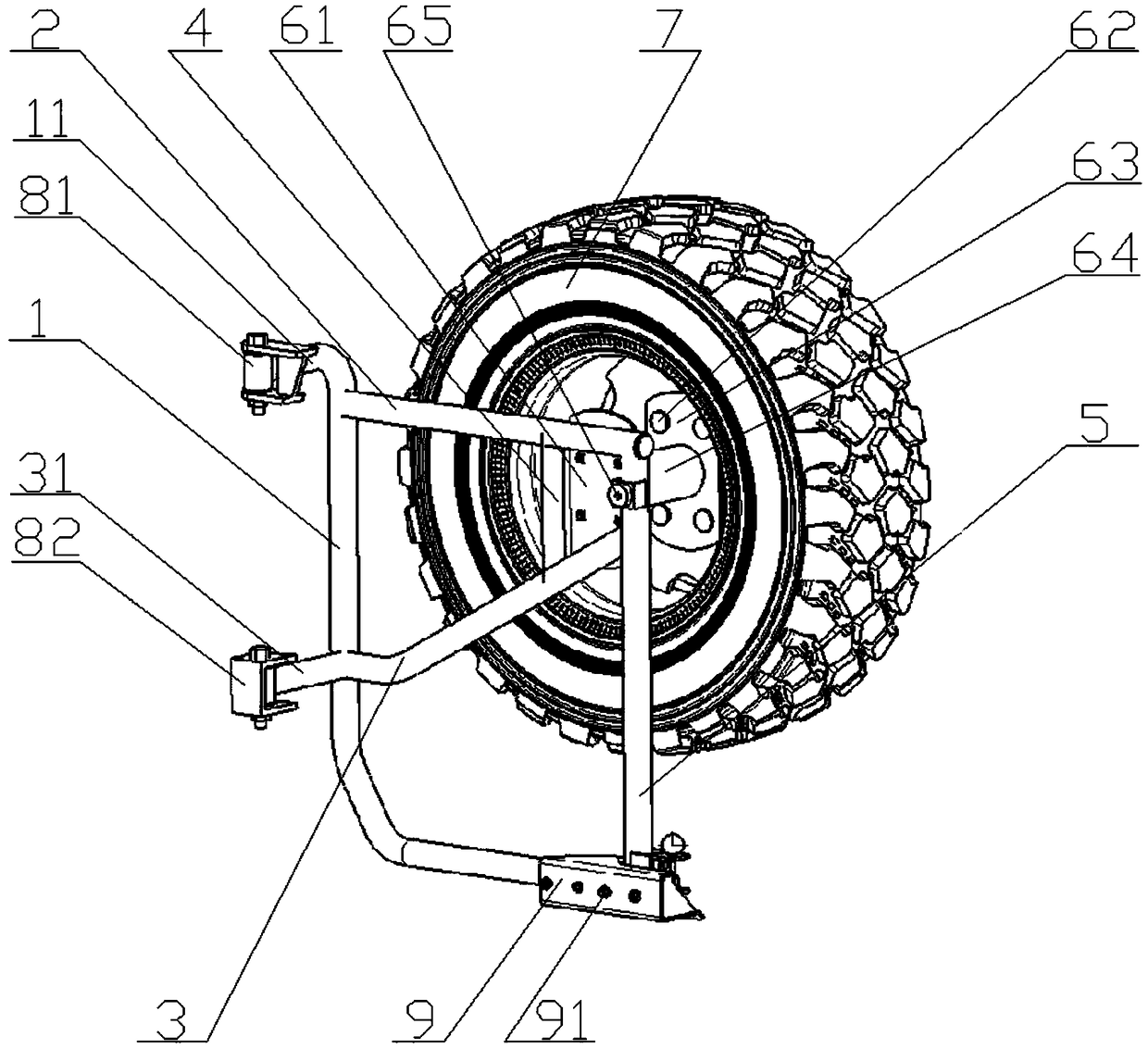

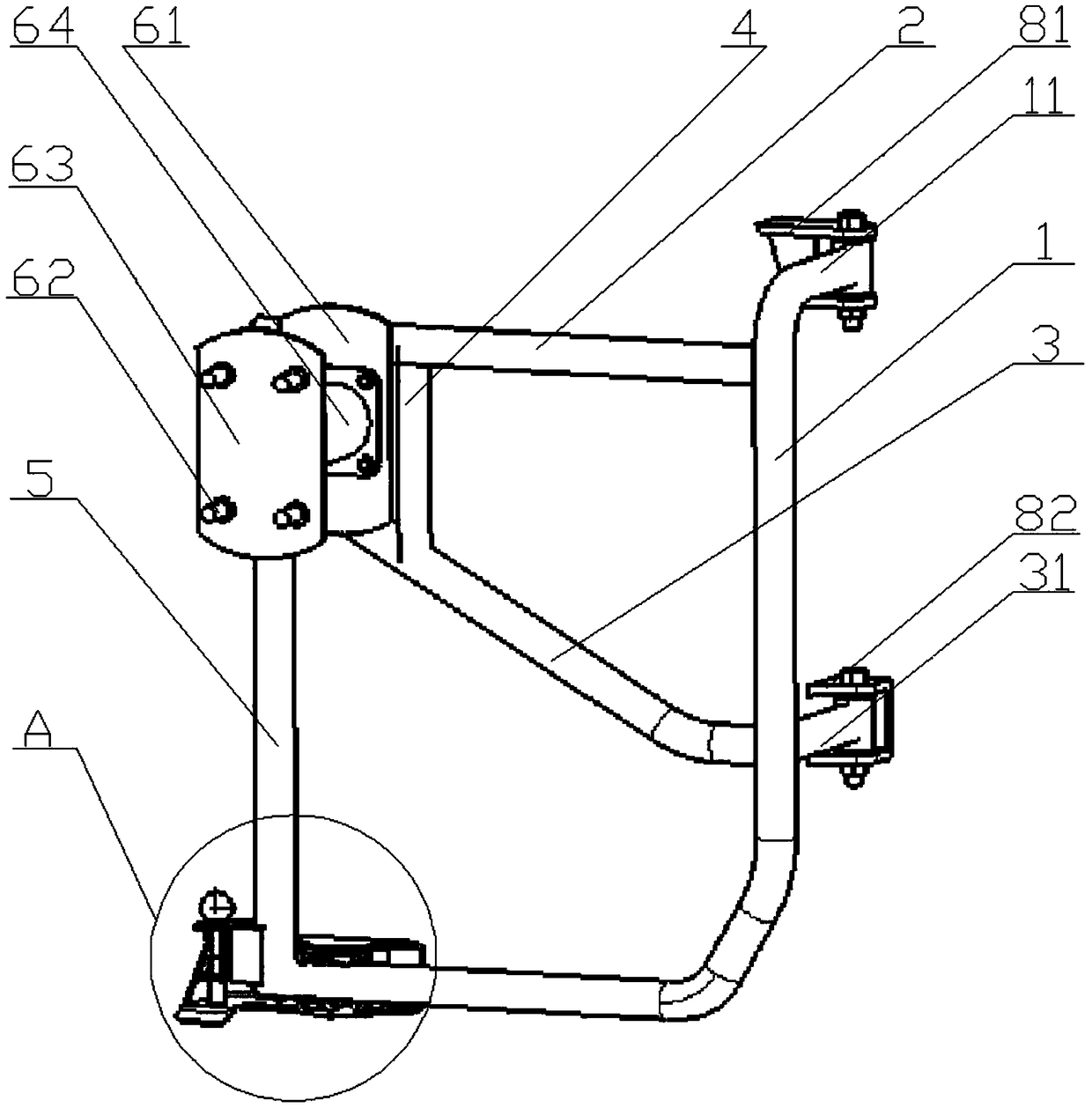

[0029] Such as Figure 1-4 As shown, a spare tire bracket assembly, including

[0030] Support mechanism, a support structure composed of multiple support rods combined with each other;

[0031] The mounting seat mechanism is provided with the first side of the support mechanism for connecting with the vehicle body;

[0032] A spare tire mounting seat is arranged on a second side of the support mechanism for mounting a spare tire, and the first side is the side opposite to the second side;

[0033] The limit mechanism (9) is arranged on the first side of the support mechanism and is used to limit and lock the support mechanism.

[0034] The support mechanism includes: a first support rod 1, a second support rod 2, a third support rod 3 and a fifth support rod 5. The upper part of the first support rod 1 is connected to the mounting seat mechanism and is L-shaped. One end of the two support rods 2 is connected to the upper part of the first support rod 1 and the other end is...

Embodiment 2

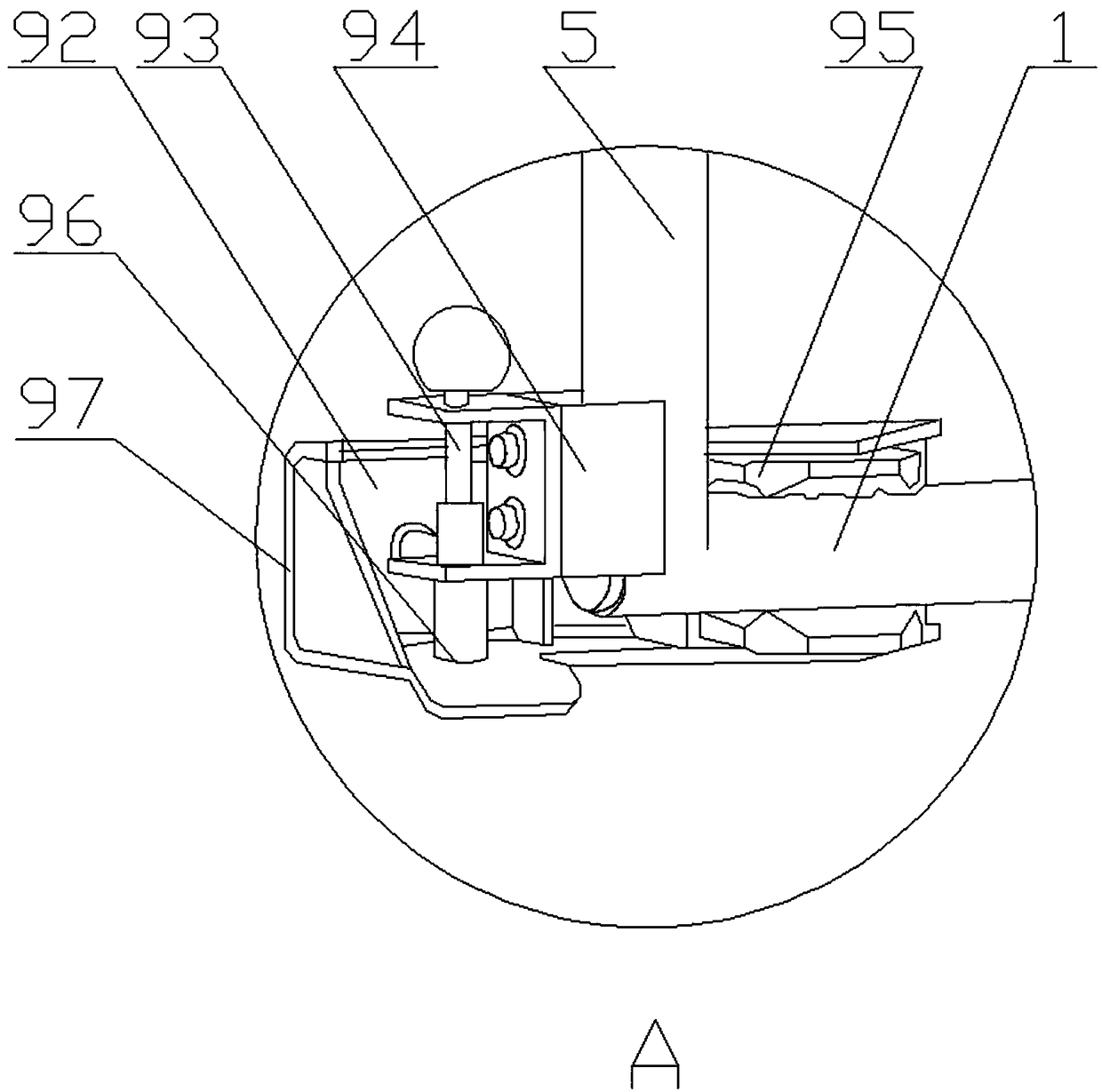

[0043] Such as Figure 4 As shown, the difference between it and Embodiment 1 is that the rear tail locking frame 92 includes a grooved bracket 97, a support block 95 arranged in the grooved bracket 97 to match the outer diameter of the first support rod 1, and a The locking hole 96 on the grooved bracket 97 and matched with the locking pin 93, and the round hole 91 arranged on the grooved bracket 97 for fixing the grooved bracket 97 to the vehicle .

[0044] In this embodiment, the rear tail locking frame in Embodiment 1 is further limited to improve its adaptability and ensure the working stability of the limit mechanism. A support block for buffering and limiting is set in the steel where it matches the first support bar, and the locking frame is set on the side of the lower end of the fifth support bar by welding, and a groove-shaped plate is arranged on the outside, and the groove-shaped The upper and lower matching assembly holes are set on the board, and the locking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com