Broadband wave-absorbing material based on 3D printing and preparation method thereof

A technology of 3D printing and wave-absorbing materials, applied in the field of wave-absorbing materials, can solve the problems of limited overall structural strength and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A broadband absorbing material based on 3D printing, which is composed of a dielectric layer and a reflective layer stacked from outside to inside, with a periodic three-dimensional structure. The dielectric layer is composed of organic resin binder, ceramic powder and absorber , the reflective layer is metal.

[0026] Further, the wave absorbing agent in the medium layer presents a gradient distribution, and the content gradually increases from the outside to the inside. The wave absorbing agent is carbonyl iron, its shape is granular, and its average particle size is 100nm. The organic resin binder is epoxy resin, and the ceramic powder is silicon carbide.

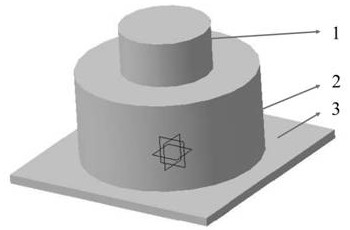

[0027] Further, the medium layer is a three-dimensional periodic array structure, and the structural unit is a cylinder with a layer number of 2. From the outside to the inside, the structural unit presents a coaxial stack from small to large, with a height of 2 mm and a radius of the bottom cylinder of 2 mm. , t...

Embodiment 2

[0037] A broadband absorbing material based on 3D printing, which is composed of a dielectric layer and a reflective layer stacked from outside to inside, with a periodic three-dimensional structure. The dielectric layer is composed of organic resin binder, ceramic powder and absorber , The reflective layer is ceramic.

[0038] Further, the wave absorbing agent in the dielectric layer presents a gradient distribution, and the content gradually increases from the outside to the inside. The wave absorbing agent is zinc oxide, which is granular in shape and has a particle size of 200nm. The organic The resin binder is amino resin, and the ceramic powder is aluminum oxide.

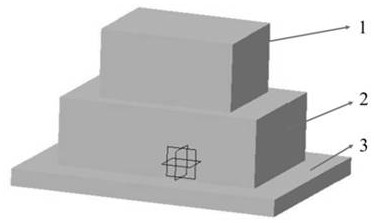

[0039] Further, the medium layer is a three-dimensional periodic array structure, the structural unit is a cuboid, the number of layers is 2, and the structural unit from the outside to the inside presents a coaxial stack from small to large, and the bottom cuboid has a length of 6mm and a width of 4mm , with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com