Urotropine distillate recycling method

An urotropine and resource-based technology, applied in chemical instruments and methods, organic chemistry, multi-stage water treatment, etc., can solve the problems of loss of ammonia and urotropine, high toxicity of waste liquid, and harm to the water environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

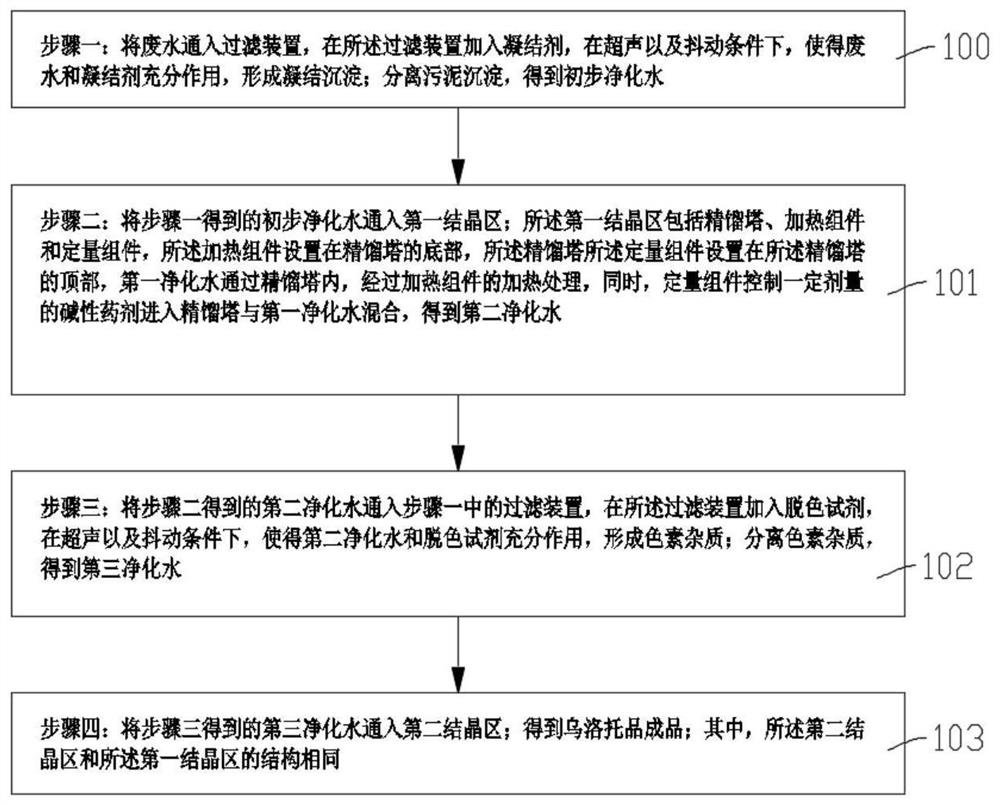

[0028] Such as Figure 1-2 A method for resource recovery of distilled liquid includes the following steps:

[0029] Step 1 100: Pass the wastewater into the filter device 1, add a coagulant to the filter device 1, and under the conditions of ultrasound and shaking, make the wastewater and the coagulant fully act to form coagulation precipitation; separate the sludge precipitation to obtain preliminary purified water ; It is worth noting that in the step 100, the COD of the wastewater is 4000-11000Mg / L;

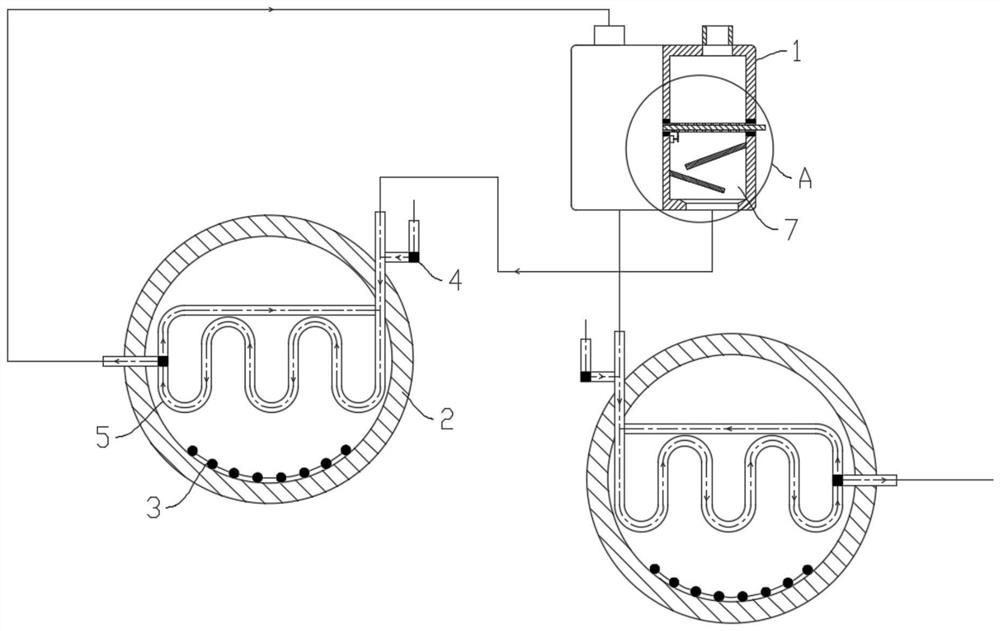

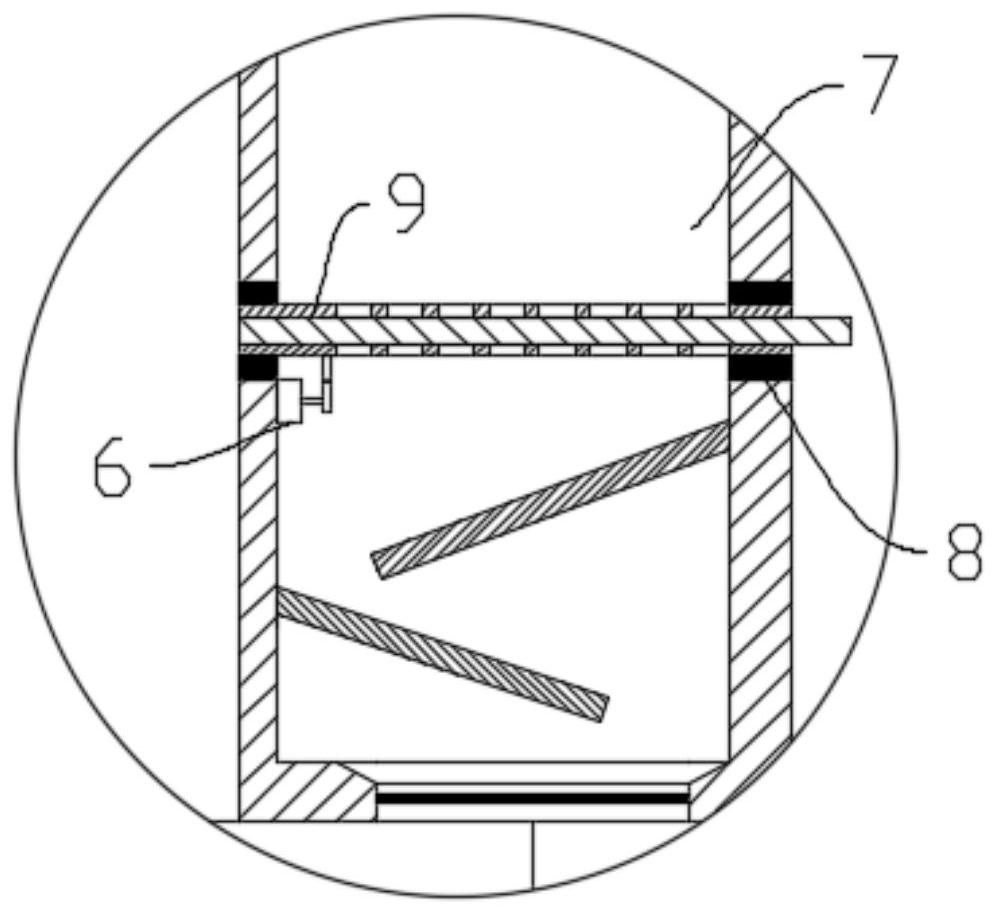

[0030] Step 2 101: pass the preliminary purified water obtained in step 1 into the first crystallization zone; the first crystallization zone includes a rectification tower 2, a heating assembly 3 and a quantitative assembly 4, and the heating assembly 3 is arranged in the rectification tower 2 The quantitative component 4 is arranged at the top of the rectification tower 2. The first purified water passes through the rectification tower 2 and is heated by the heating compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com