Method and device for regulating air pressure in an ultra-high-speed elevator shaft

A technology of air pressure adjustment and elevator shaft, which is applied in the direction of transportation and packaging, elevators and elevators in buildings, etc. It can solve the problems of affecting the comfort of the car, the noise outside the hall, the obvious difference in the effect of the vent, and the uncertain effect on the spot. Achieve the effects of improving the lack of self-closing force, reducing the piston effect, and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

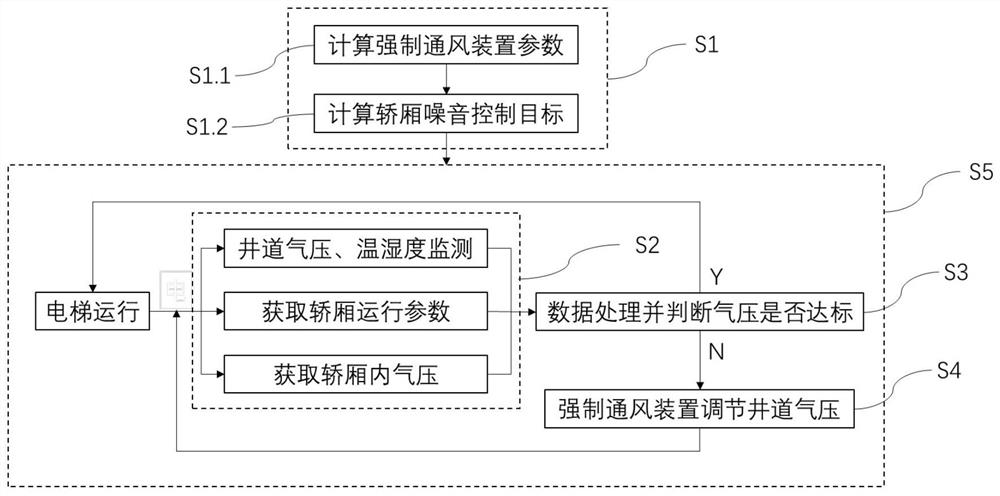

[0039] Embodiment 1: This embodiment is a method for adjusting the air pressure of an ultra-high-speed elevator shaft.

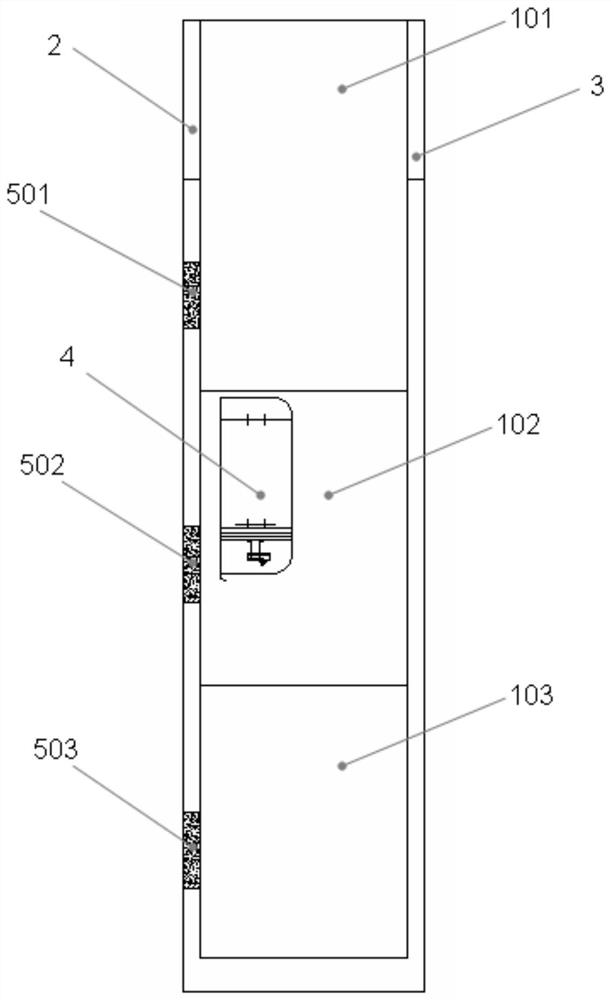

[0040] like figure 2 As shown, the ultra-high-speed elevator hoistway includes hoistway top 101, hoistway middle 102, hoistway bottom 103, hoistway front wall 2, hoistway rear wall 3, and the car 4 runs up and down in the hoistway. The method for adjusting the air pressure of the ultra-high-speed elevator shaft of this embodiment does not require large-area natural ventilation openings in the shaft, but only needs to open the ventilation openings of the forced ventilation pressure regulating device in the shaft. The vents in this embodiment are provided on the front wall of the well, wherein the vents 501 are provided on the top 101 of the well, the vents 502 are provided in the middle 102 of the well, and the vents 503 are provided on the bottom 103 of the well, and each vent is equipped with forced ventilation Pressure regulating device (not shown in the...

Embodiment 2

[0050] Embodiment 2: This embodiment is another method for adjusting the air pressure of an ultra-high-speed elevator shaft.

[0051] The hoistway parameters and car parameters in this embodiment are the same as those in the first embodiment; in this embodiment, a set of forced ventilation and pressure regulating device is set at the top of the hoistway, and the forced ventilation opening is opened at the top of the hoistway, and at the same time, it is set on the sidewall of the hoistway at the bottom of the hoistway. figure 1 The natural vent used in the prior art shown; the forced ventilation pressure regulating device includes two axial fans: one axial fan and two axial fans; the two axial fans are connected in parallel to the direction of forced ventilation in opposite directions of air flow. There is an air duct in the air duct, and the air door has two working positions: position 1 and position 2; when the air door is in position 1, only the axial flow fan 1 is connected...

Embodiment 3

[0061] Embodiment 3: This embodiment is an air pressure regulating device for an ultra-high-speed elevator shaft.

[0062] like figure 2 As shown, the ultra-high-speed elevator hoistway includes hoistway top 101, hoistway middle 102, hoistway bottom 103, hoistway front wall 2, hoistway rear wall 3, and the car 4 runs up and down in the hoistway. The hoistway air pressure regulating device in this embodiment includes a controller (not shown in the figure), a hoistway air pressure and temperature and humidity monitoring device (not shown in the figure), a forced ventilation pressure regulating device (not shown in the figure), the hoistway air pressure and The temperature and humidity monitoring device and the forced ventilation pressure regulating device are all connected to the controller. The shaft air pressure and temperature and humidity monitoring device monitors the shaft air pressure, temperature and humidity data in real time and sends it to the controller, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com