Horizontal lithium battery pole piece splitting machine

A lithium battery and slitting machine technology, which is applied in the direction of battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as imperfect structures and unsatisfactory functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A horizontal lithium battery pole piece slitting machine is used for cutting battery pole pieces during the lithium battery production process. The specific structure and working principle of the slitter will be described in detail below.

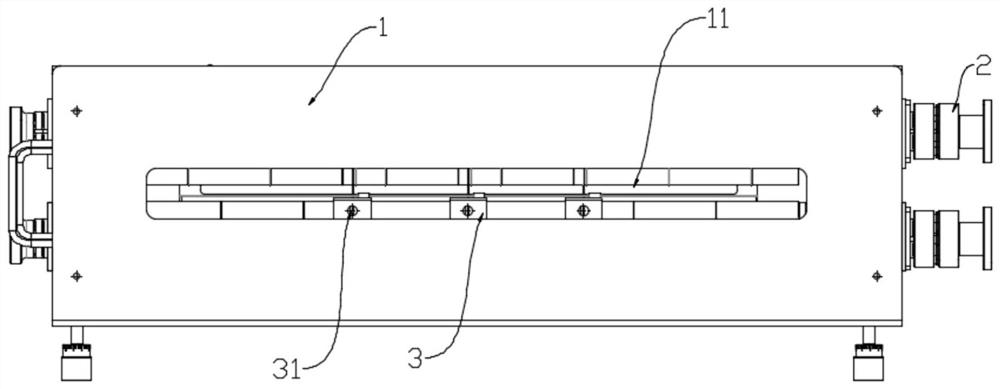

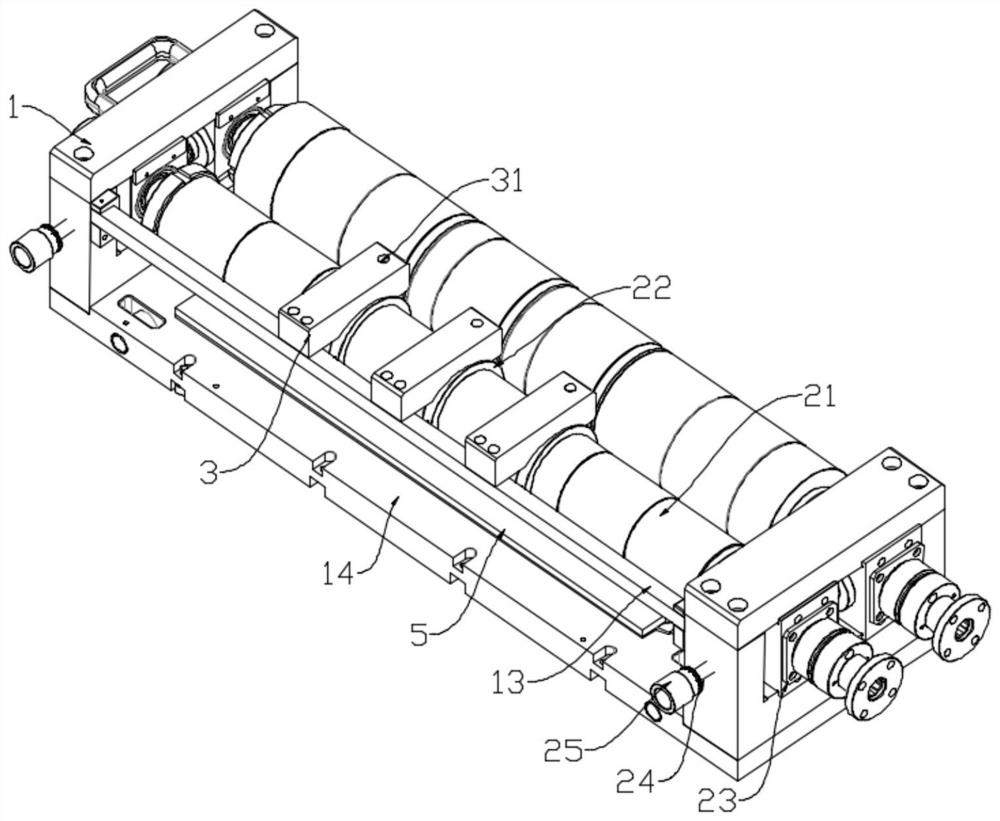

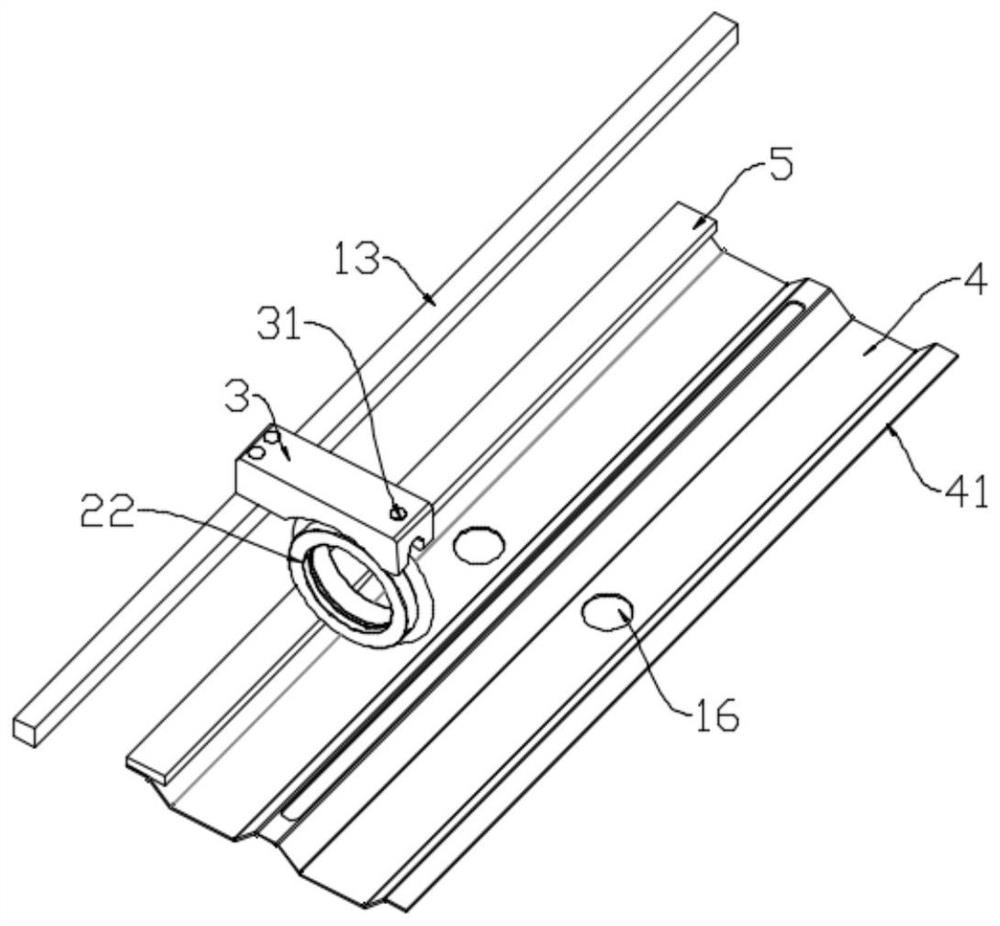

[0039] Such as Figure 1 to Figure 4 As shown, the slitting machine includes a frame 1, a cutting device 2, an alcohol wiping device 3 and a negative pressure dust removal device. The frame 1 includes a bottom plate 14, a base, a pressing plate, a top plate and side plates. Wherein, the bottom plate 14 is arranged at the bottom of the slitting machine, and is a rectangular structure. The base is a "concave" structure with grooves, and has two, the bottom width of which is consistent with the bottom width of the bottom plate 14, which are respectively arranged at the front and rear ends of the bottom plate 14. closed above. The side plates are arranged on both sides of the bottom plate 14 in the width direction, and respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com