Rolling-cut transverse shearing device

A rolling-cutting and cross-cutting technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problem of short shearing length, inability to realize thin plate and strip cross-cutting, cut-to-length segmentation, shearing, etc. Cutting and other problems, to achieve the effect of reducing wear, simple and reasonable structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

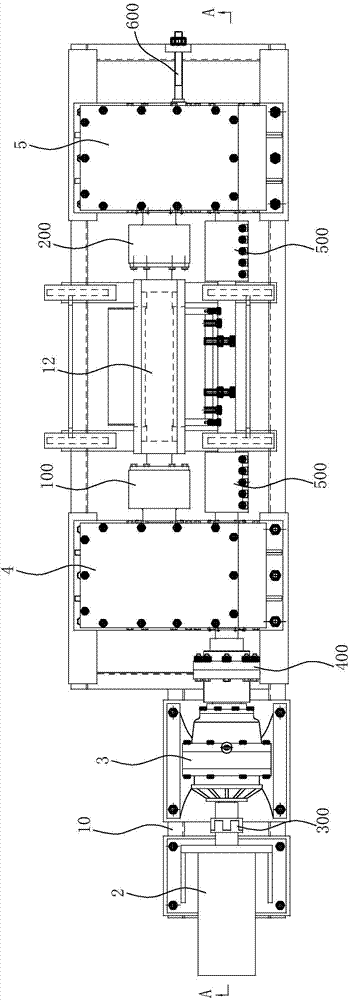

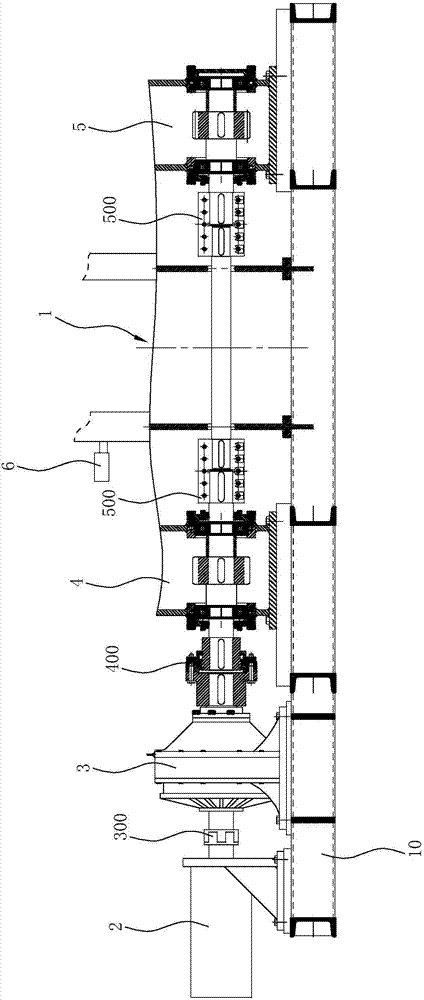

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] Such as Figure 1~6 As shown, the roll-cutting type cross-shearing device of this embodiment is applied in the shearing process of plate and strip materials. The rails 900 are connected, and the discharge end is connected with the discharge rail 800 . The rolling shearing device in this embodiment includes a frame 10 , an upper and lower shearing mechanism 1 and a drive assembly connected to the upper and lower shearing mechanism 1 . The driving assembly in the present embodiment includes servo motor 2, cycloid reducer 3, first gearbox 4 and second gearbox 5, the output shaft of servo motor 2 is connected with cycloid reducer 3 through a quincunx coupling 300 The input shaft transmission connection, the input end of the first gearbox 4, the second gearbox 5 is connected with the output shaft transmission of the cycloid reducer 3 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com