Magnetic fly ash adsorption material as well as preparation method and application thereof

An adsorption material and fly ash technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as easy agglomeration of adsorption liquid, uncontrollable magnetic fly ash process, and decreased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

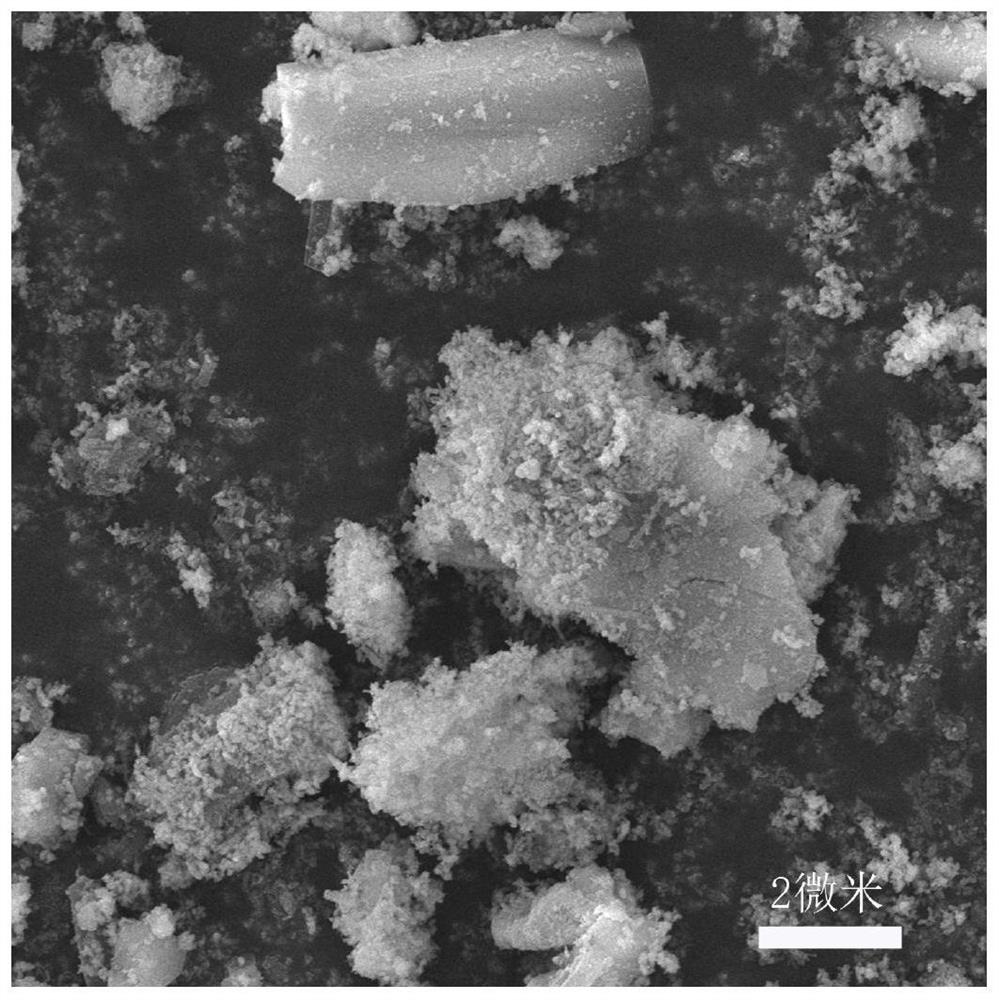

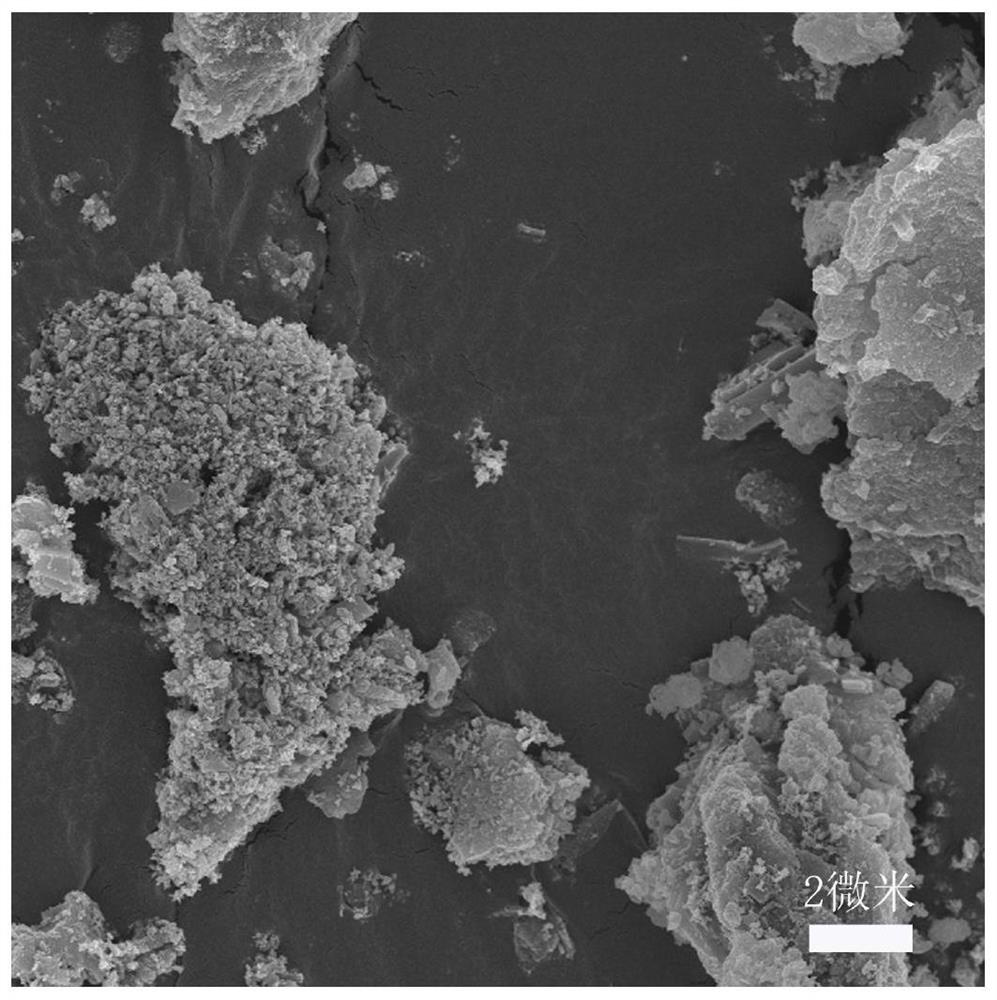

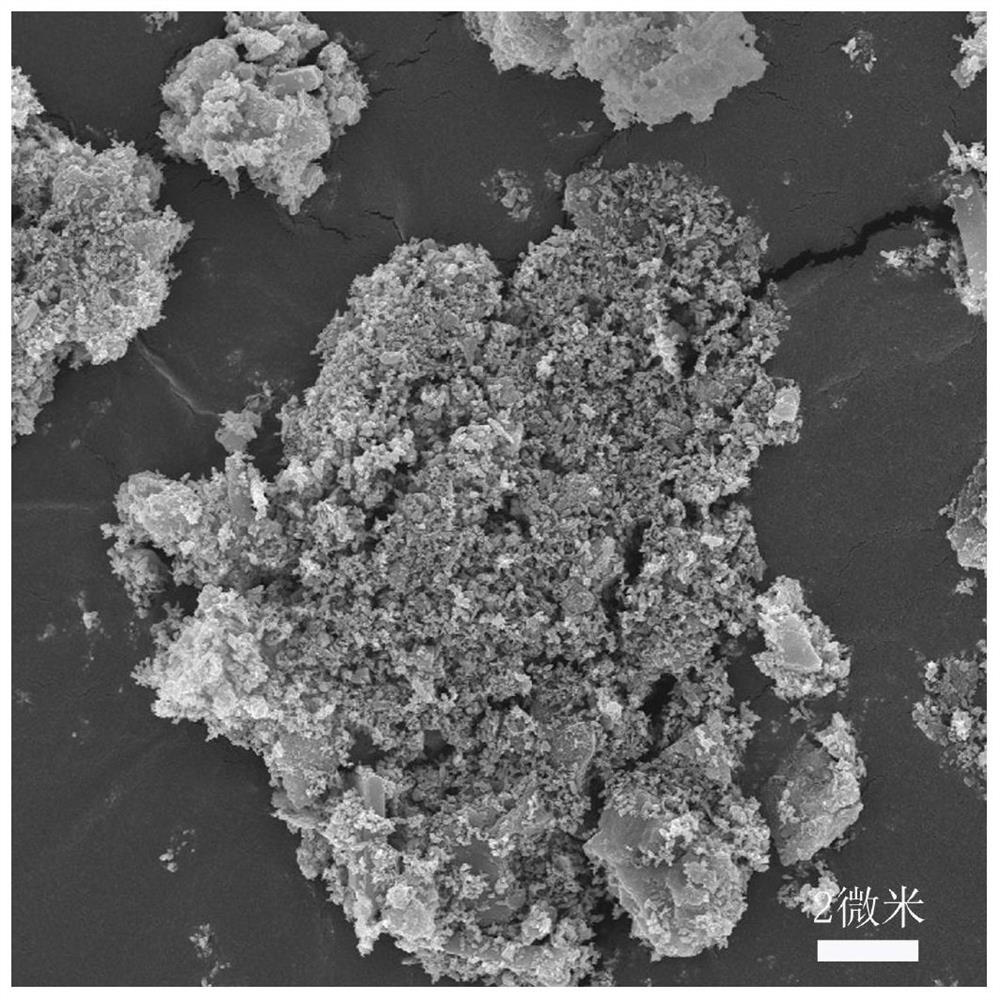

Image

Examples

Embodiment 1

[0031] (1) Pretreatment of fly ash

[0032] ①Acid modification: Take 40g of raw fly ash with a size of 5 microns and disperse them in 200mL of 1M hydrochloric acid solution, stir mechanically at room temperature for 30min, then filter, wash with water until neutral, and ultrasonically Disperse and then freeze-dry to obtain acid-modified fly ash.

[0033] ②Surface state modification: Take 0.5g of the acid-modified fly ash powder obtained in step ① and disperse it in 500mL PVP (polyvinylpyrrolidone, molecular weight: Mw=20000) solution with a mass fraction of 5%. After ultrasonic treatment for 30min, maintain the temperature at 30 Under the condition of ℃, stir mechanically for 20 hours, and finally wash the excess PVP surfactant by centrifuging with water to obtain a PVP-modified fly ash material.

[0034] (2) Preparation of fly ash@MIL-88B composite

[0035] Add 0.5g of the fly ash material obtained in process ② in step (1) to 100mL of the Pluronic F127 aqueous solution with...

Embodiment 2

[0041] (1) Pretreatment of fly ash

[0042] ①Acid modification: Take 12g of raw fly ash with a size of 5 microns and disperse it in 200mL of 1M hydrochloric acid solution, stir mechanically at room temperature for 20min, then filter, wash with water until neutral, and ultrasonically Disperse and then freeze-dry to obtain acid-modified fly ash.

[0043] ②Surface state modification: Take 0.3g of the acid-modified fly ash powder obtained in step ① and disperse it in 500mL PVP (polyvinylpyrrolidone, molecular weight: Mw=15000) solution with a mass fraction of 0.1%. After ultrasonic treatment for 30min, maintain the temperature at 20 Under the condition of ℃, stir mechanically for 10 h, and finally wash the redundant PVP surfactant with water centrifugation to obtain the fly ash material modified by PVP.

[0044] (2) Preparation of fly ash@MIL-88B composite

[0045]Add 0.28g of the fly ash material obtained in the process ② in step (1) to 100mL of the Pluronic F127 aqueous soluti...

Embodiment 3

[0051] (1) Pretreatment of fly ash

[0052] ①Acid modification: Take 35g of raw fly ash with a size of 10 microns and disperse it in 200mL of 2M hydrochloric acid solution, stir mechanically at room temperature for 40min, then filter, wash with water until neutral, and sonicate in an ultrasonic cleaner. Disperse and then freeze-dry to obtain acid-modified fly ash.

[0053] ②Surface state modification: Take 1g of the acid-modified fly ash powder obtained in step ① and disperse it in 500mL PVP (polyvinylpyrrolidone, molecular weight: Mw=25000) solution with a mass fraction of 5%, and after ultrasonic treatment for 40min, maintain the temperature at 40°C Under the condition of mechanical stirring for 15 hours, finally the excess PVP surfactant was washed by centrifugation with water to obtain a PVP-modified fly ash material.

[0054] (2) Preparation of fly ash@MIL-88B composite

[0055] The fly ash material of process 2. gained in 0.8g step (1) is joined in the Pluronic F127 aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com