Sterilization and disinfection device used before processing of meat can

A sterilizing device and canned food technology, applied in the field of canned food processing, can solve the problems of meat food deterioration and affecting the health of eaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

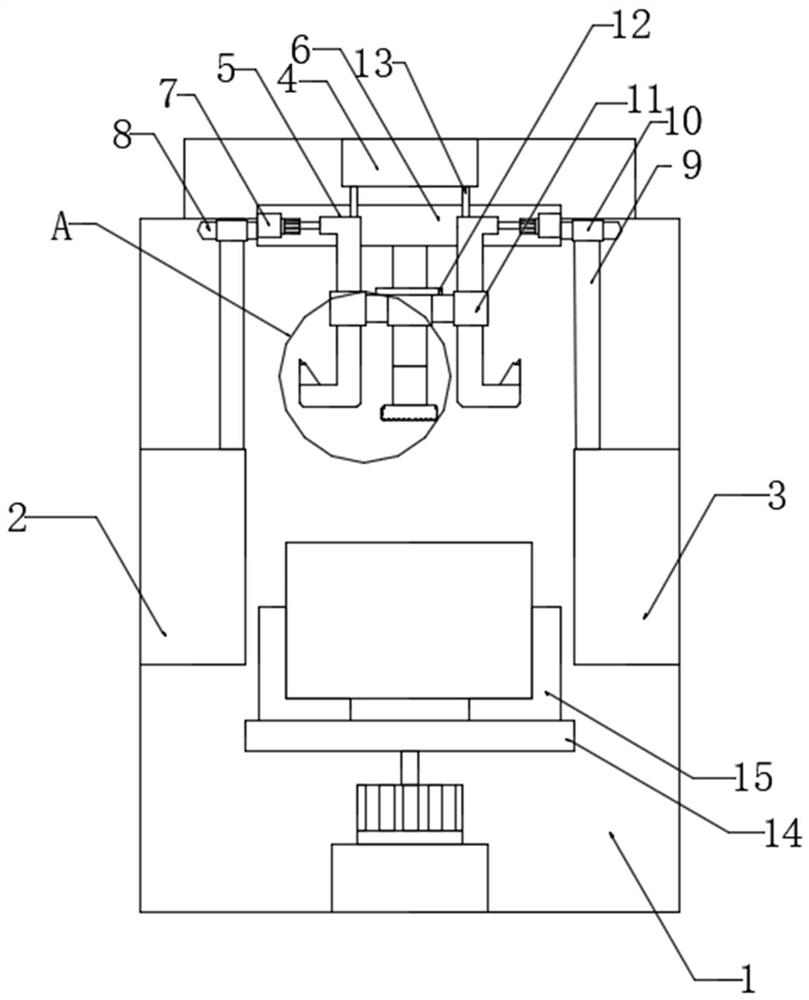

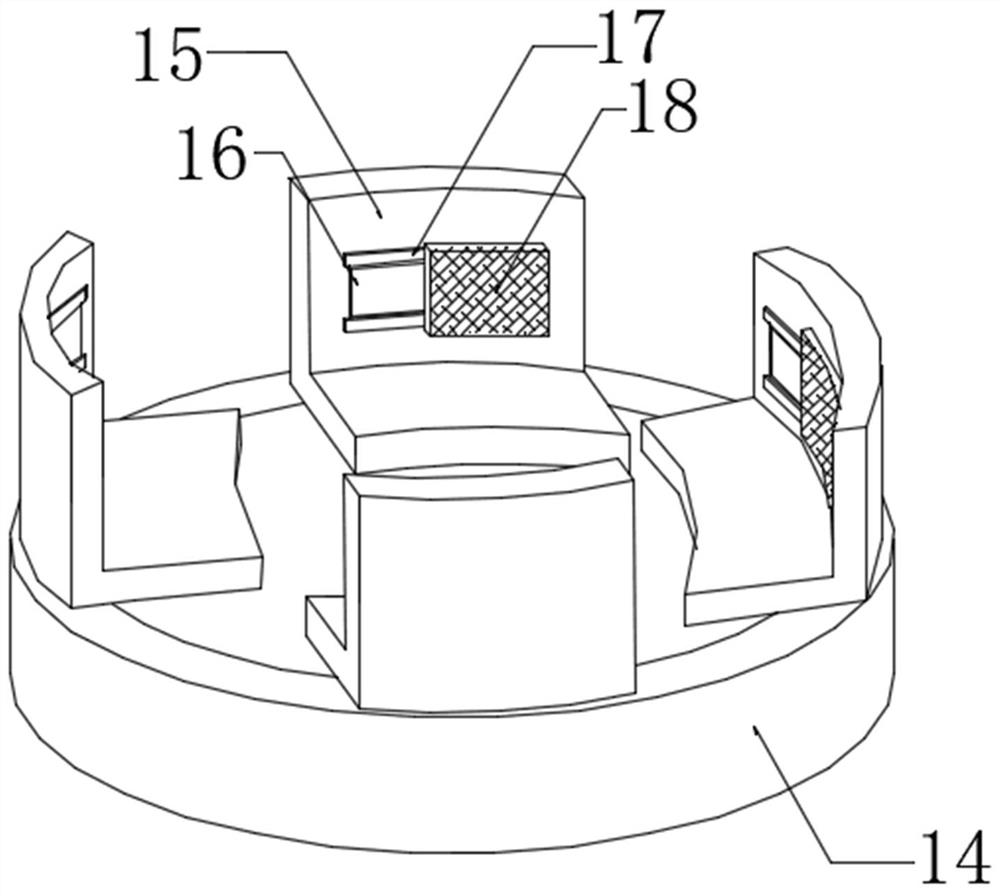

[0030] Such as Figure 1-6As shown, a sterilizing device for canned meat before processing, including an installation cylinder (1), the two sides of the installation cylinder (1) are respectively provided with a placement port (2) and a removal port (3), and the installation cylinder (1) There are several installation blocks (11) inside, the installation blocks (11) are arc-shaped, the middle parts of several installation blocks (11) are installed with connecting rods (5), and the top of the installation cylinder (1) is installed with a support plate (6), one side of the top of the connecting rod (5) is installed with the push rod of the first push rod motor (7), and the other end of each first push rod motor (7) is installed on the support plate (6) Inside, the bottom of the support plate (6) is equipped with an extension rod (35), and the middle part of the extension rod (35) is equipped with a shielding plate (12);

[0031] Sleeve pipes (27) are installed at both ends of s...

Embodiment 2

[0036] Such as Figure 1-6 As shown, a sterilizing device for canned meat before processing, including an installation cylinder (1), the two sides of the installation cylinder (1) are respectively provided with a placement port (2) and a removal port (3), and the installation cylinder (1) There are several installation blocks (11) inside, the installation blocks (11) are arc-shaped, the middle parts of several installation blocks (11) are installed with connecting rods (5), and the top of the installation cylinder (1) is installed with a support plate (6), one side of the top of the connecting rod (5) is installed with the push rod of the first push rod motor (7), and the other end of each first push rod motor (7) is installed on the support plate (6) Inside, the bottom of the support plate (6) is equipped with an extension rod (35), and the middle part of the extension rod (35) is equipped with a shielding plate (12);

[0037] Sleeve pipes (27) are installed at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com