Weeding device for agricultural planting

An agricultural, work box technology, applied in the direction of agriculture, spraying devices, agricultural machinery and implements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

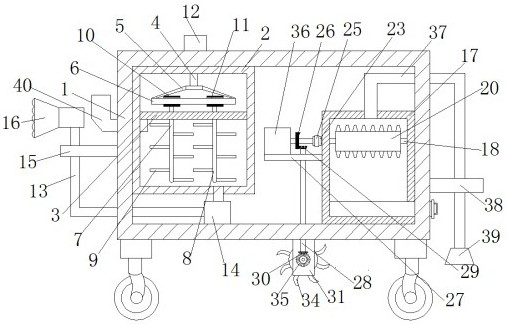

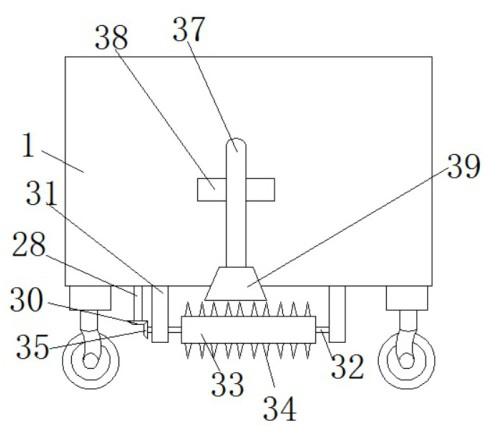

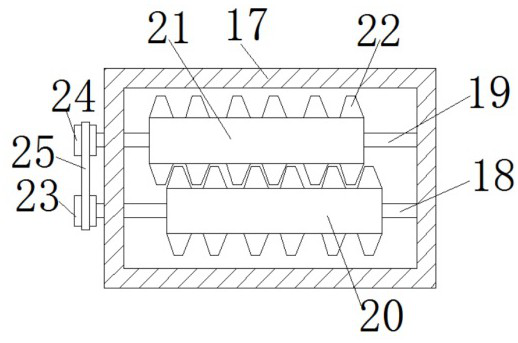

[0028] refer to Figure 1-5 , a weeding device for agricultural planting, comprising a work box 1, a mixing and spraying mechanism and a crushing mechanism are provided in the work box 1, a weeding mechanism is provided at the bottom of the work box 1, and the stirring and spraying mechanism includes a stirring box 2, a dividing plate 3 , drive rotating rod 4, rotating frame 5, tooth steel ring 6, first stirring rod 7, second stirring rod 8, two stirring blades 9, first gear 10, second gear 11, stirring motor 12, chemical spraying Pipe 13, spraying pump 14, branch tube plate 15 and nozzle 16, mixing box 2 is located in working box 1, mixing box 2 is fixedly connected to working box 1, partition 3 is fixedly connected to mixing box 2, and driving rotating rod 4 is connected to working box 1 and the top of the mixing box 2 are rotationally connected, the rotating frame 5 is fixedly connected to one end of the driving rotating rod 4, the toothed steel ring 6 is fixedly connected ...

Embodiment 2

[0039] refer to Figure 1-5 , a weeding device for agricultural planting, comprising a work box 1, a mixing and spraying mechanism and a crushing mechanism are provided in the work box 1, a weeding mechanism is provided at the bottom of the work box 1, and the stirring and spraying mechanism includes a stirring box 2, a dividing plate 3 , drive rotating rod 4, rotating frame 5, tooth steel ring 6, first stirring rod 7, second stirring rod 8, two stirring blades 9, first gear 10, second gear 11, stirring motor 12, chemical spraying Pipe 13, spraying pump 14, branch tube plate 15 and nozzle 16, mixing box 2 is located in working box 1, mixing box 2 is welded to working box 1, partition 3 is welded to mixing box 2, and driving rotating rod 4 is connected to working box 1 and the top of the mixing box 2 are rotationally connected, the rotating frame 5 is welded to one end of the driving rotating rod 4, the toothed steel ring 6 is welded to the rotating frame 5, and the first stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com