Hanging basket for building construction

A technology of building construction and basket frame, which is applied in the direction of construction, building structure, scaffolding accessories, etc. It can solve the problems of construction personnel's difficulty in construction, small working space, and easy hardening again, so as to increase the construction space and work scope , Reasonable structural design, and the effect of improving agility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

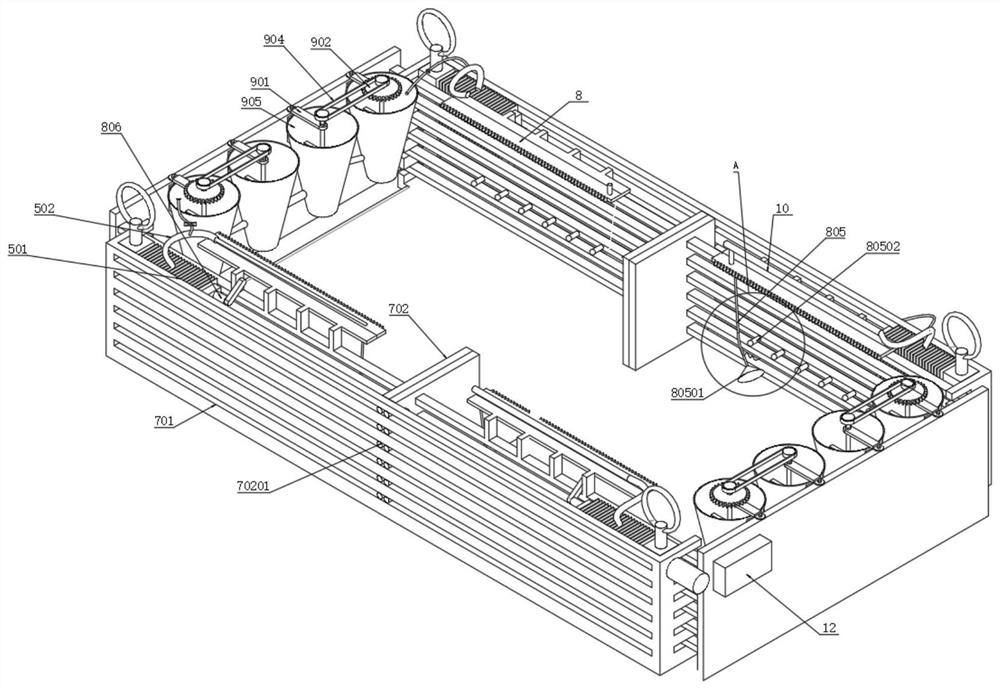

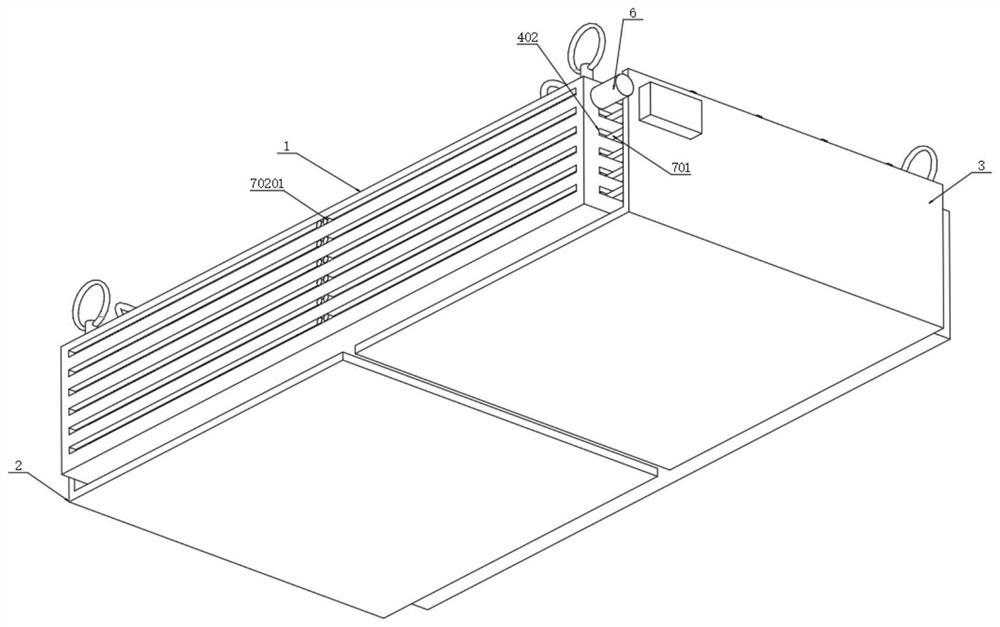

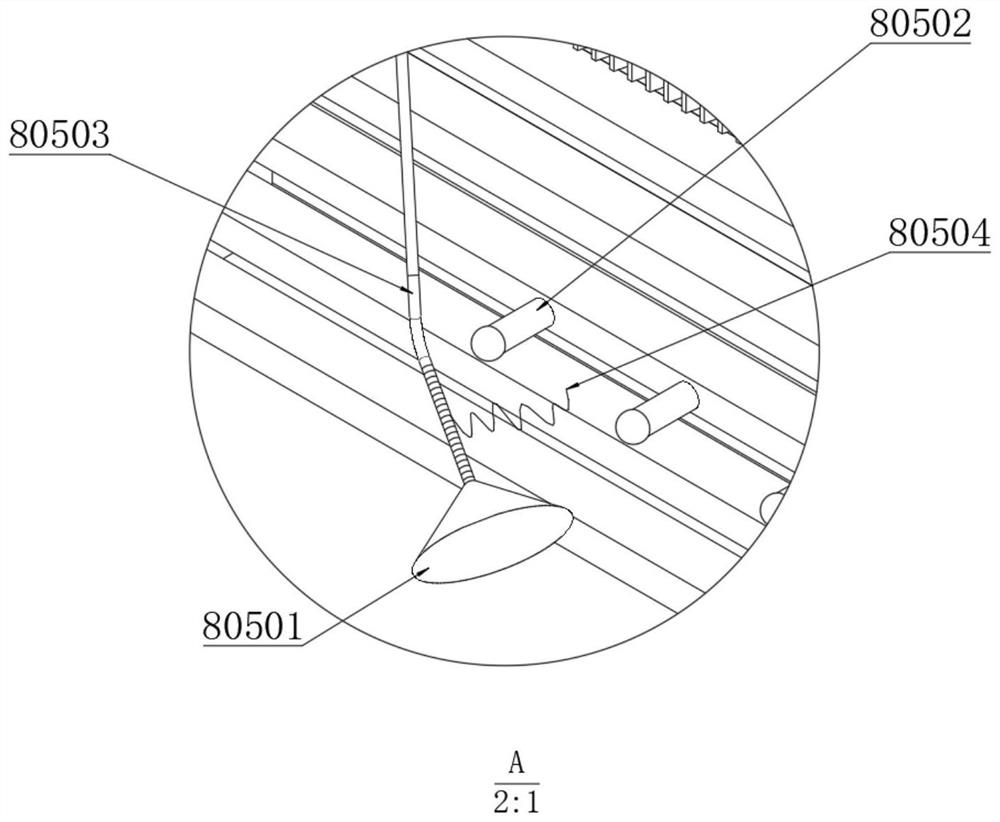

[0032] The following is attached figure 1 - Figure 7 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

[0033] A hanging basket for building construction includes an inner basket frame 1, a pressure bag mechanism 5, a synchronous gear mechanism 8, a mixing group mechanism 9 and an electric cylinder 11, such as Figure 1 to Figure 4As shown, the two sides of the inner basket 1 are provided with a first side basket 2 and a second side basket 3, and the first side basket 2 and the second side basket 3 are adjusted left and right in the inner basket 1, and the inner basket A drive motor 6 is installed on the side of the frame 1, and a two-way screw 601 for adjusting the left and right displacement of the first side basket 2 and the second side basket 3 in the inner basket 1 is installed on the transmission shaft of the drive motor 6; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com