Aerodynamic noise reducing structure of centrifugal gas compressor

A gas compressor and aerodynamic noise technology, which is applied in the field of compressor noise reduction, can solve the problems of compressor supercharger noise, supercharger high-frequency noise, etc., to reduce air resistance, reduce processing accuracy, and be easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

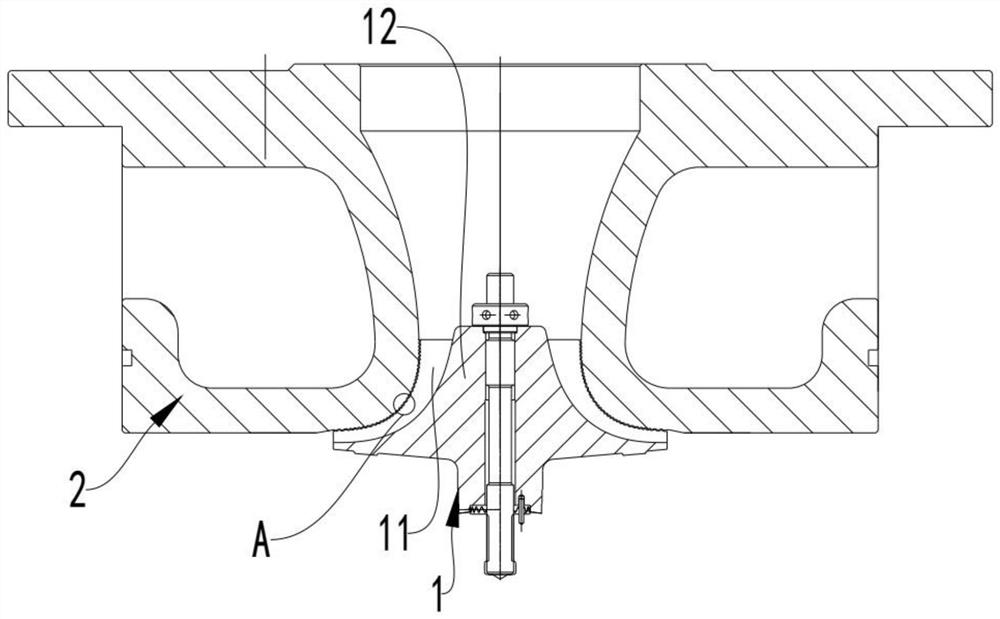

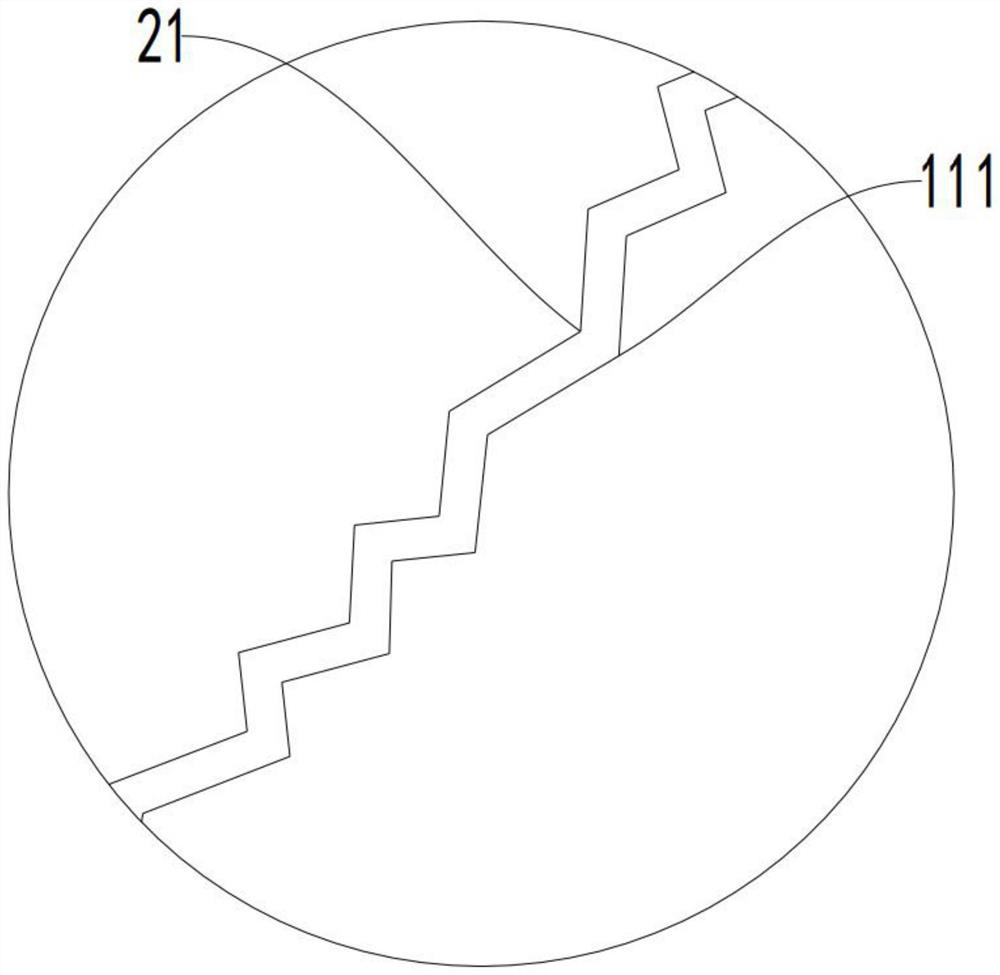

[0029] like figure 1 and 2 shown,

[0030] A structure for reducing aerodynamic noise of a centrifugal gas compressor, comprising an impeller 1 and a cover plate 2; the cover plate cover is arranged above the impeller 1; the impeller 1 comprises a plurality of alternately arranged long blades 11 and The short blade 12; the processing profile of the long blade 11 is provided with a plurality of grooves 111 equidistantly arranged along the processing profile, and the processing profile on the inner side of the cover plate 2 is provided with all the grooves 111. The groove 111 matches the bump 21 .

[0031] Preferably, the cross section of the groove 111 is triangular, and the depth of the groove 111 is 0.5-1.5 mm.

Embodiment 2

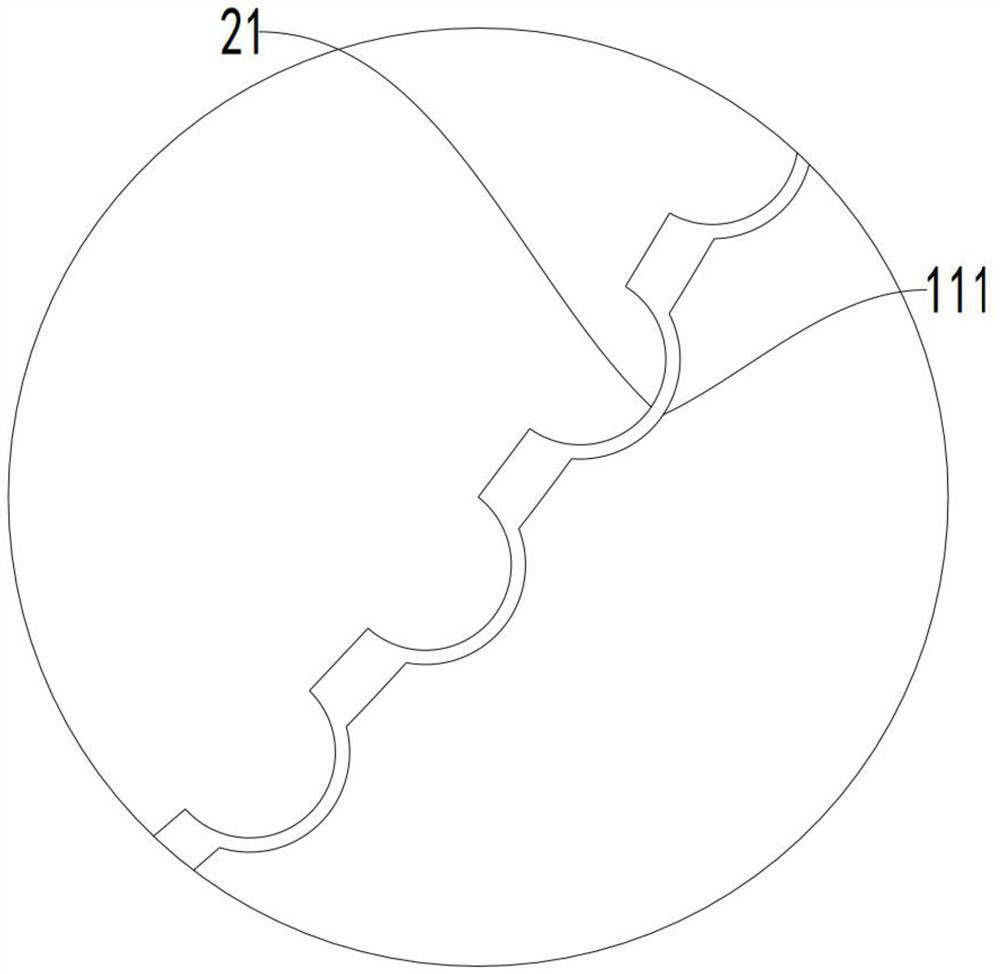

[0033] like figure 1 and 3 As shown, a structure for reducing aerodynamic noise of a centrifugal gas compressor includes an impeller 1 and a cover plate 2; the cover plate cover is arranged above the impeller 1; the impeller 1 includes a plurality of alternately arranged long The blade 11 and the short blade 12; the machining profile of the long blade 11 is provided with a plurality of grooves 111 arranged at equal intervals along the machining profile, and the machining profile on the inner side of the cover plate 2 is provided with a plurality of grooves 111. There are bumps 21 matching the grooves 111 .

[0034] Preferably, the cross section of the groove 111 is a semicircle, and the depth of the groove 111 is 0.5-1.5 mm.

Embodiment 3

[0036] like figure 1 and 4 As shown, a structure for reducing aerodynamic noise of a centrifugal gas compressor includes an impeller 1 and a cover plate 2; the cover plate cover is arranged above the impeller 1; the impeller 1 includes a plurality of alternately arranged long The blade 11 and the short blade 12; the machining profile of the long blade 11 is provided with a plurality of grooves 111 arranged at equal intervals along the machining profile, and the machining profile on the inner side of the cover plate 2 is provided with a plurality of grooves 111. There are bumps 21 matching the grooves 111 .

[0037] Preferably, the cross section of the groove 111 is rectangular, and the depth of the groove 111 is 0.5-1.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com