a cloth cutting machine

The technology of a cloth cutting machine and a cloth cutting knife is used in the cutting of textiles, papermaking, and textile materials. and the effect of falling gently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

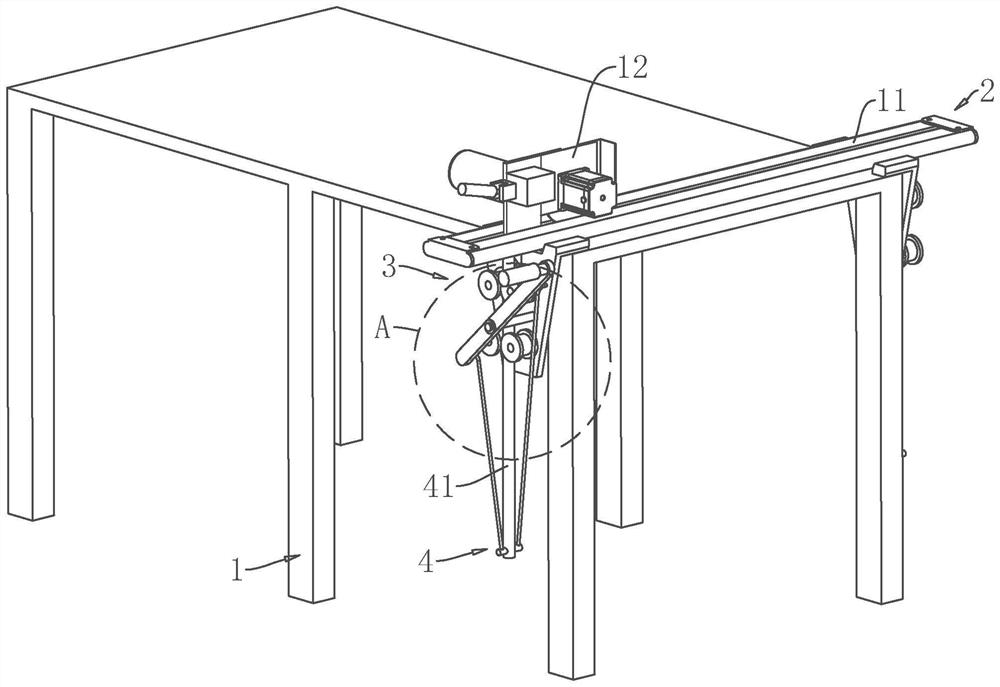

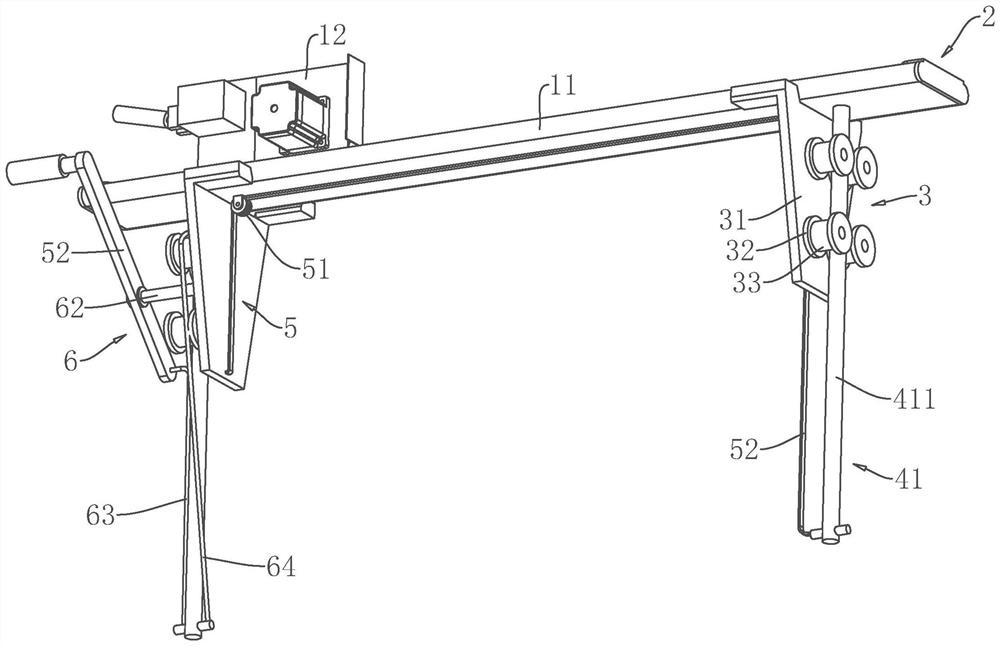

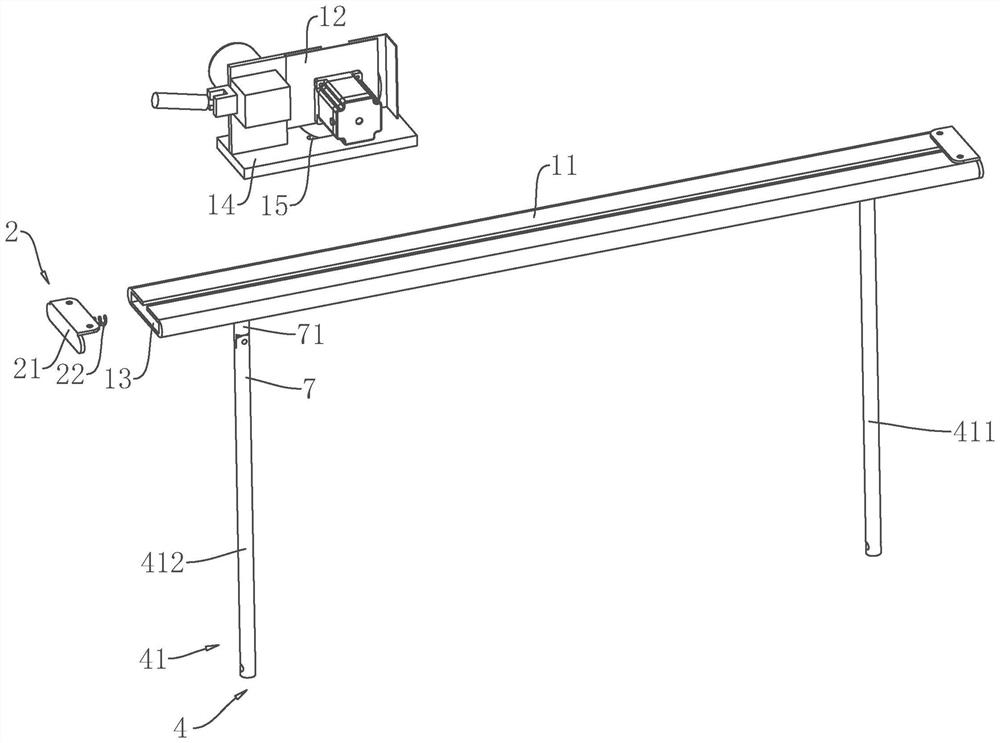

[0032] The following is attached Figure 1-5 The application is described in further detail.

[0033] The embodiment of the present application discloses a cloth cutting machine. refer to figure 1 and figure 2 , the cloth cutting machine includes a workbench 1. A guide plate 11 and a cloth cutting knife 12 are arranged on the top surface of the workbench 1 . A buffer component 2 , a support component 3 , a limit component 4 , a lifting component 5 and a lifting component 6 are also installed on the workbench 1 .

[0034] refer to figure 1 and image 3, the guide plate 11 is elongated and placed horizontally on the top surface of the workbench 1, both ends of the guide plate 11 are located outside the workbench 1, and the top surface of the guide plate 11 is provided with a strip-shaped guide groove 13, The guide groove 13 is arranged along the guide plate 11 , and both ends of the guide groove 13 are also located outside the workbench 1 . The cross section of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com