Speed-adjustable and anti-jamming yarn conveyor

An anti-jamming and yarn feeder technology, which is applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problems of finished product quality problems, the inability to adjust the position of the yarn storage wheel, and the inability of workers to perceive intuitively, so as to achieve faster speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

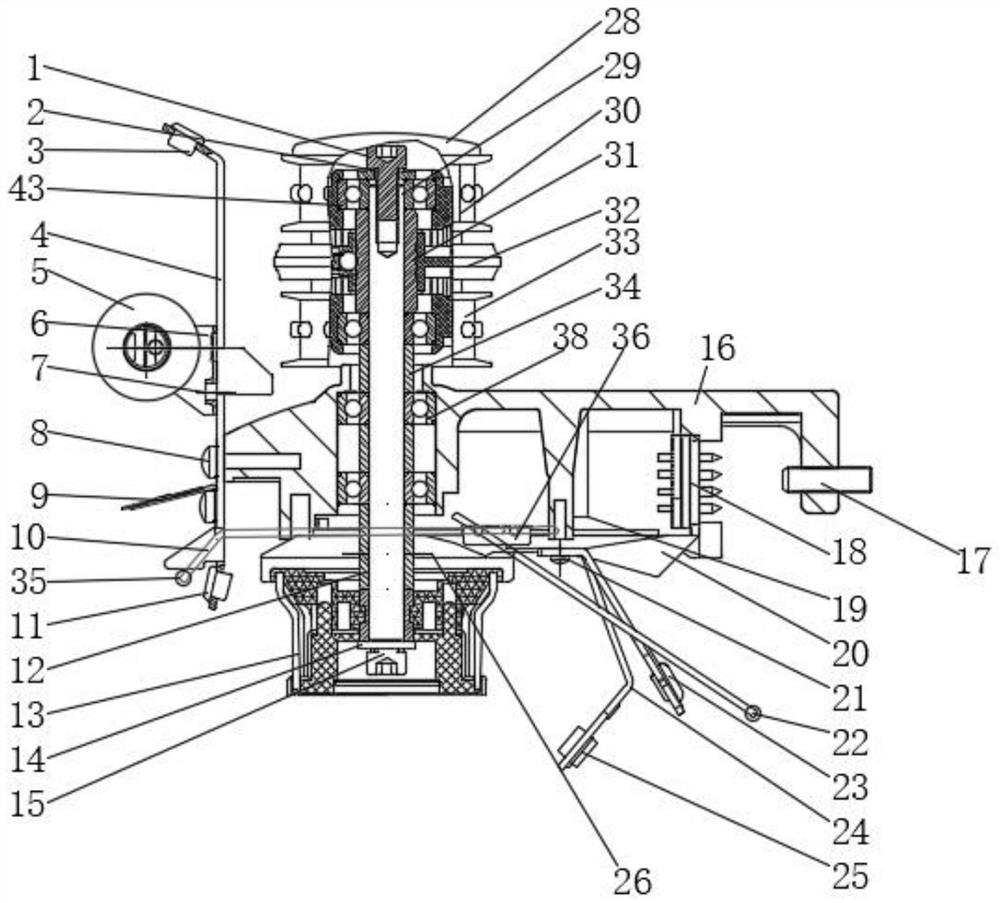

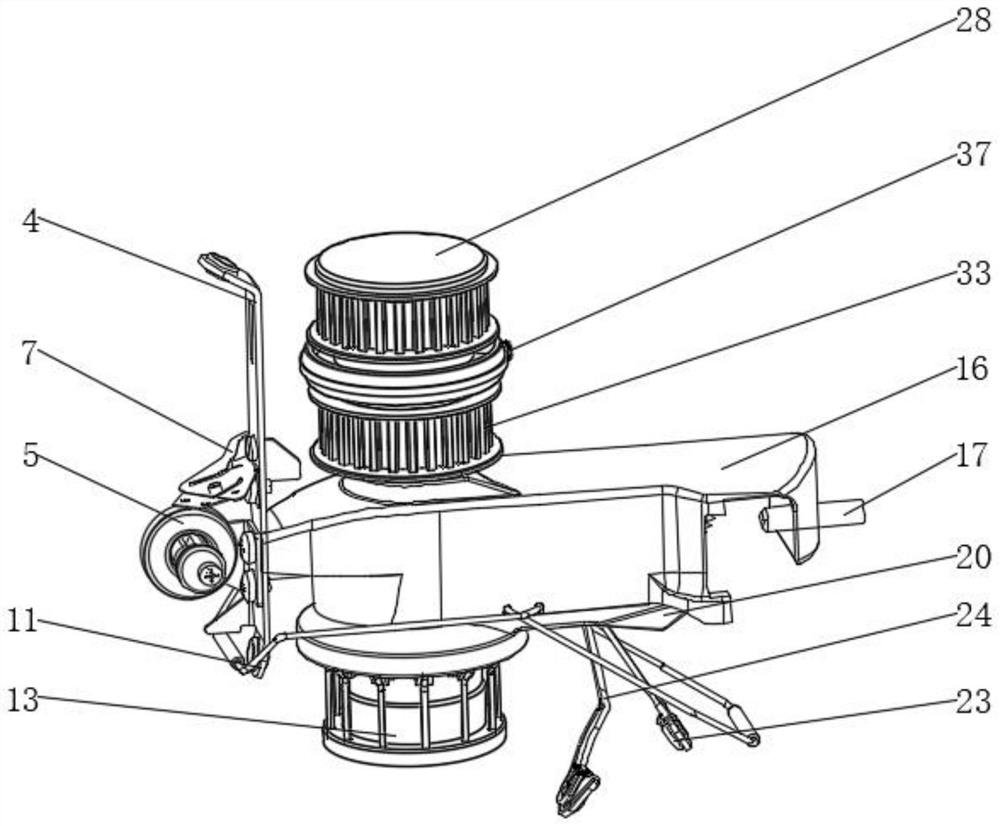

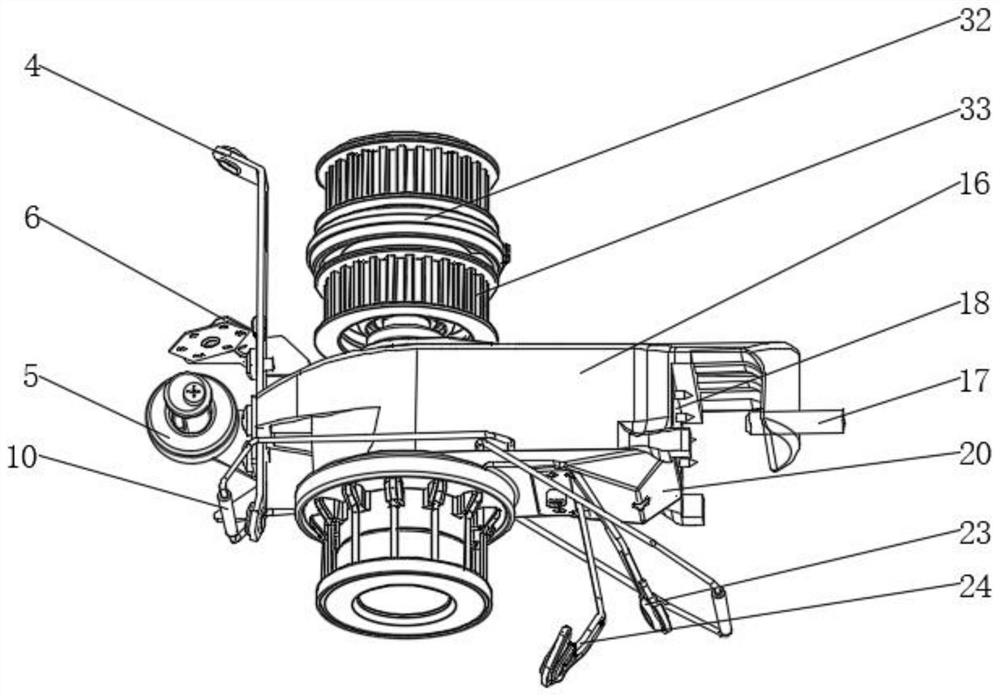

[0026] A housing 16, a lower cover 20, a main shaft 29, a clutch core 31, a clutch bonding member 32, a width plate 4, a width strip 4, a numeral 5, a nipper # 6. The cylindrical screw 1, the elastic gasket 2, and the front pride 10, the outer side of the inner portion of the housing 16 is connected to the feed plate 4, and the internal fixing sleeve of the jumper plate 4 has a porcelain eye one 3, which The left end of the feeder 4 is fixedly connected to the feed bonding member 5, and the left end of the jumper plate 4 is connected by a bolt, and the interior sliding connection of the clamping plate 6 has a tray screw one 7. The outer side of the disk head screw one 7 is connected to the inner side of the feeder plate 4, and the inner sliding of the jumper plate 4 has a tray screw two 8, and the outer side of the cutting screws. The inside of the housing 16 is connected by a threaded connection.

[0027] Wherein, the internal fixation of the housing 16 has two bearing one 38, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com