Spray head suitable for carbide slag flue gas desulfurization

A technology of sprinkler head and carbide slag, which is applied in the field of flue gas desulfurization, can solve the problems such as the inability to make full use of the solubility and high reactivity of carbide slag, and achieve the effects of eliminating alkaline scaling factors, improving desulfurization efficiency, and reducing desulfurization energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

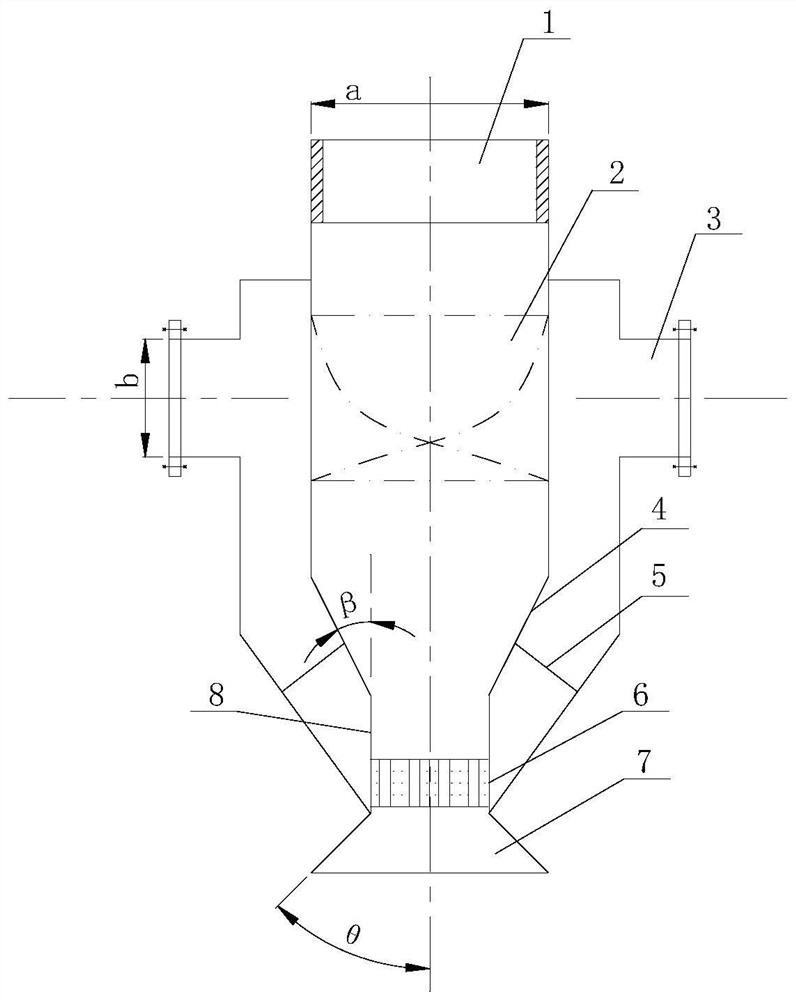

[0027] Such as figure 1 As shown, the spray head suitable for calcium carbide slag flue gas desulfurization in this embodiment includes a main channel 1 and an outer channel 3 surrounding the main channel 1, and an inlet and an injection port 7 are respectively provided at both ends of the main channel 1 , between the inlet and the injection port 7, a swirl guide body 2, a constriction section 4, a throat 8 and a mixing suction port 6 are arranged in sequence, and an inlet is provided on the outer channel 3, and the outer channel 3 passes through the mixing suction port 6 and the main channel 1, the fluids in the main channel 1 and the outer channel 3 are mixed at the mixing inlet 6 and ejected through the injection port 7.

[0028] In this embodiment, the main channel 1 is mainly used for the circulation of the main fluid (i.e. circulating desulfurization slurry); it can be understood that the main channel 1 has an inlet for the main fluid to enter and an injection port 7 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com