Rolling element having integrated electronics for use in rolling bearing

A technology of rolling bearings and rolling elements, applied in rolling contact bearings, bearing components, bearings in rotating motion, etc., can solve problems such as shortened service life and disadvantageous circuit boards, and achieve time and cost saving, easy implementation, and stress reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the individual figures, identical components are always provided with the same reference symbols and are therefore usually also named or mentioned only once in each case.

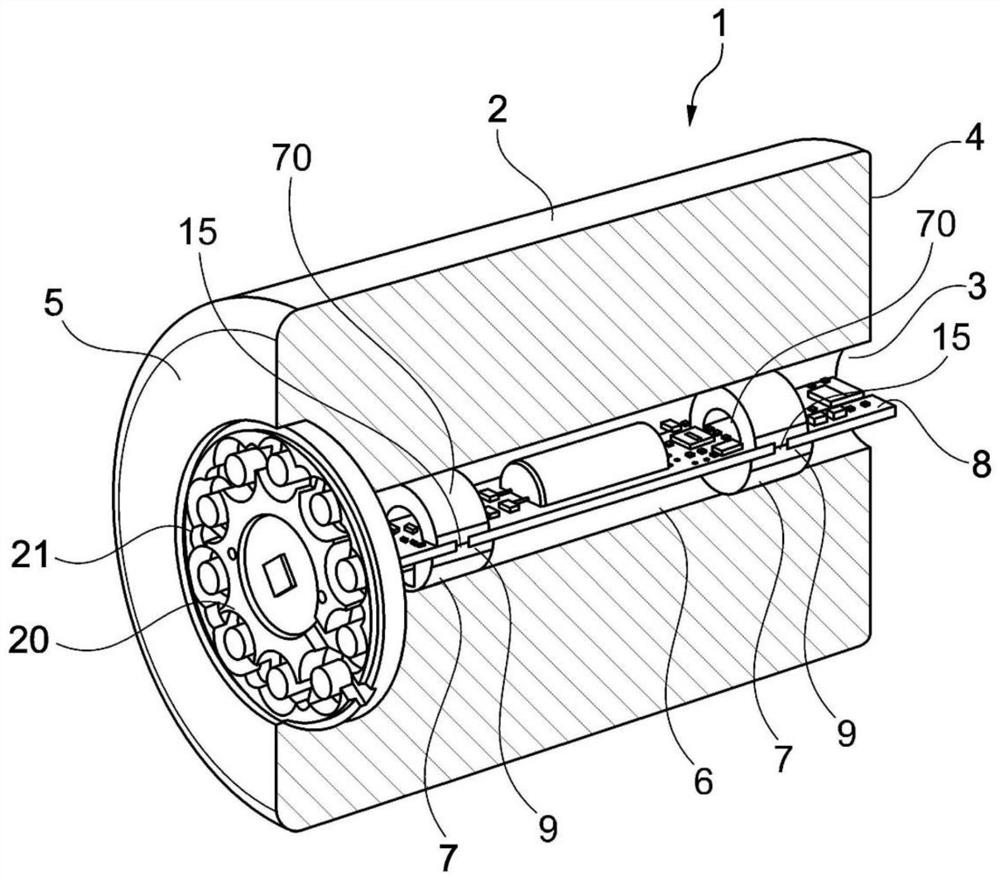

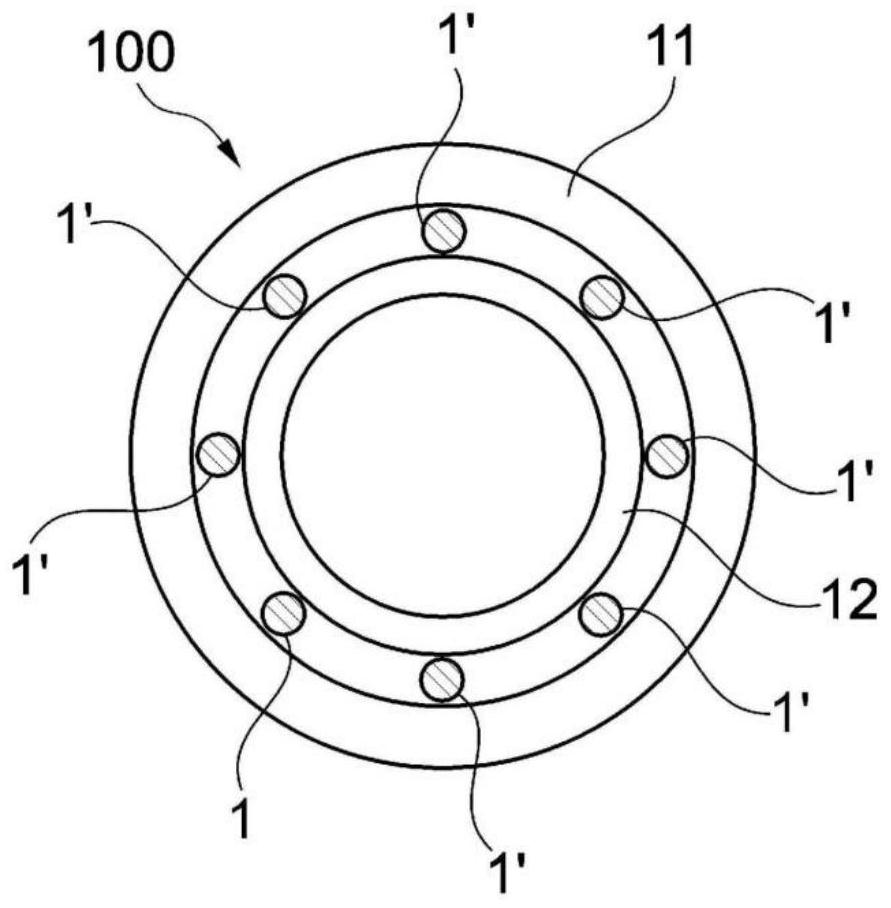

[0039] figure 1 A schematic view of a rolling body 1 according to an exemplary embodiment of the invention is shown. Such a rolling body 1 is mounted in a rolling bearing and serves for the movable guidance of the first bearing ring 11 and the second bearing ring 12 to one another, in particular for the movable guiding of the inner ring 12 arranged in the outer ring 11 of the anti-rotation arrangement. Movement guidance (see image 3 ). In this case, usually a plurality of rolling bodies are arranged between the outer ring 11 and the inner ring 12 and roll on the running surfaces of the outer ring 11 and the inner ring 12 .

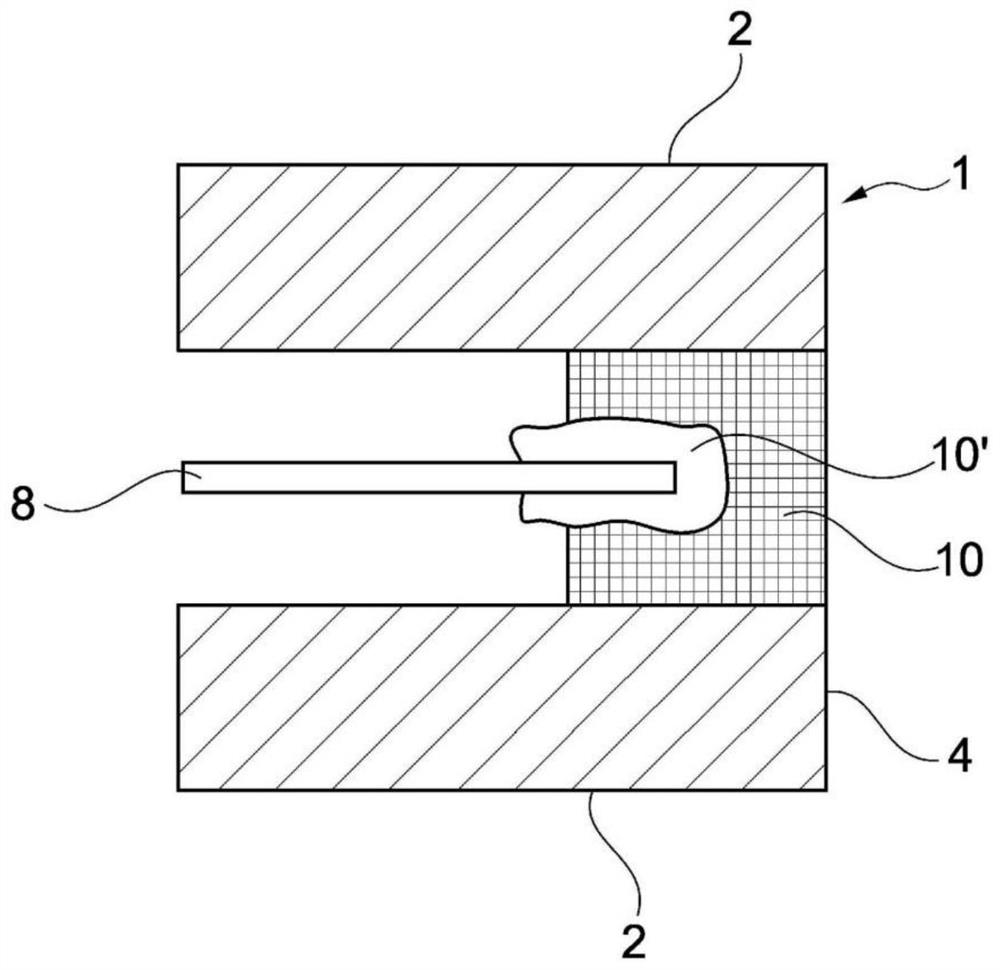

[0040] The rolling element 1 here comprises a cylindrical or substantially conical body with an outer sleeve 2 serving as a running surface on which an outer ring 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com