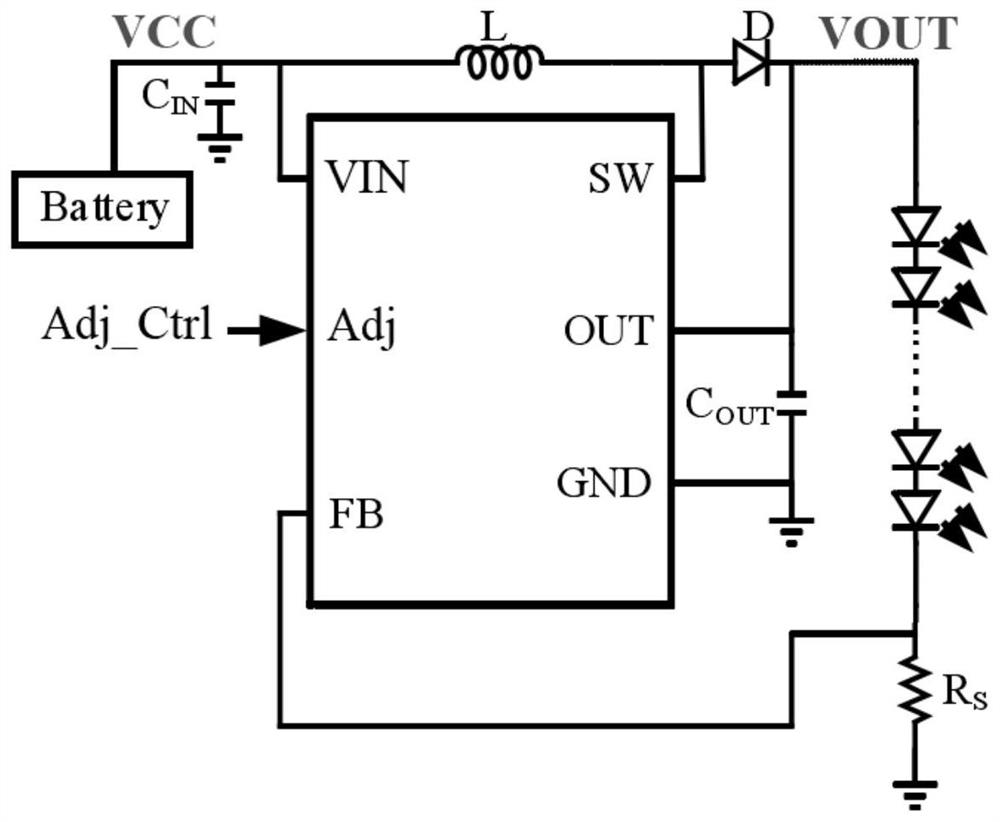

High-precision and high-reliability LED vehicle lamp driving circuit

A technology for LED vehicle lights and driving circuits, applied in the field of integrated circuits, can solve problems such as power supply voltage and substrate potential fluctuations, common mode noise, etc., and achieve the effects of improving protection accuracy, avoiding common mode noise interference, and improving circuit reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

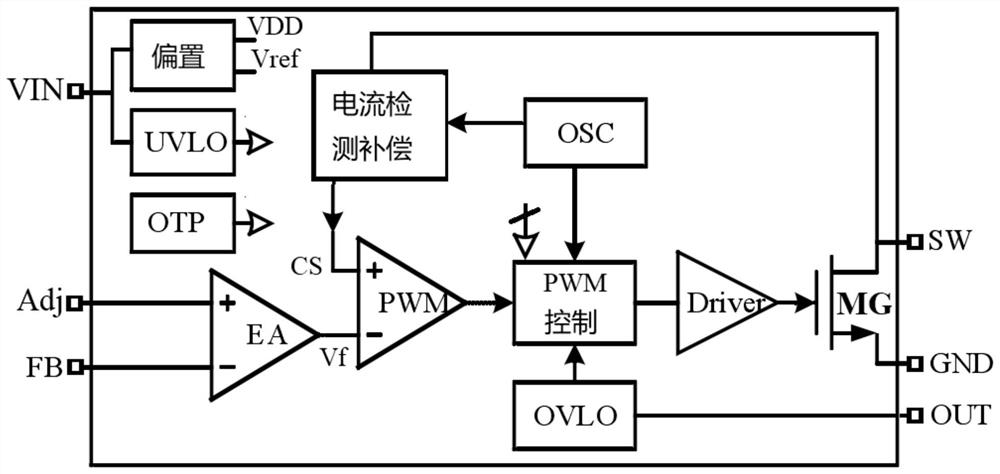

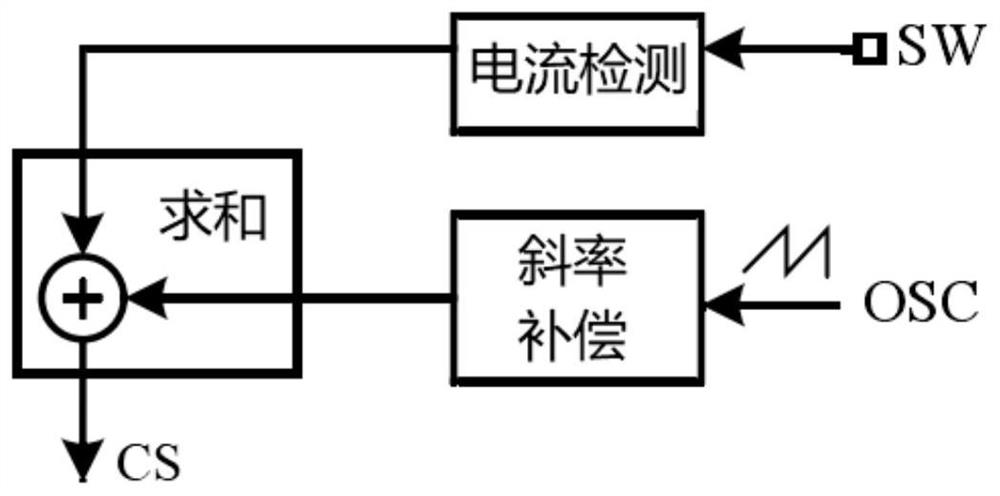

[0056] figure 2 It is a structural diagram of the high-precision and high-reliability LED lamp driving circuit of the present invention. The high-precision and high-reliability LED lamp driving circuit includes: a bias module, an error amplification module, a current detection compensation module, a pulse width modulation module (PWM), a PWM control module, a driver module (Driver), and an oscillator module (OSC) , High-precision and high-reliability under-voltage protection circuit (UVLO), high-precision and high-reliability over-voltage protection circuit (OVLO), high-precision and wide-voltage range over-temperature protection circuit (OTP) and power switch NMOS tube MG;

[0057] The functions realized by the above-mentioned circuit modules are as follows:

[0058] The bias module mainly provides reference voltage and bias voltage for other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com