Low-voltage-driven flexible light-emitting device and preparation method and application thereof

A technology for low-voltage driving and light-emitting devices, applied in the field of materials, can solve the problems of driving voltage process optimization, potential safety hazards for users, and high driving voltage, and achieve the effects of improving use safety, improving overall strength, and reducing driving voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

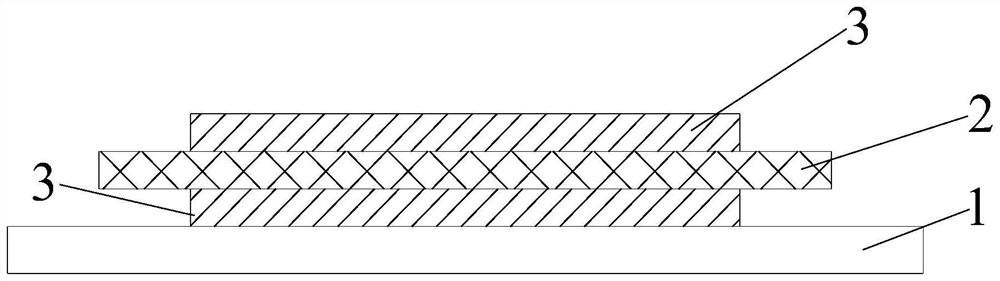

[0068] This embodiment provides a figure 1 The low-voltage driven flexible light-emitting device shown includes a flexible base layer 1 and a light-emitting layer 2 disposed on the flexible base layer 1; conductive silver layers are respectively provided on both sides of the light-emitting layer 2 3.

[0069] The preparation method of the flexible light-emitting device driven by the low voltage comprises the following steps:

[0070] (1) Spray silver nanowire solution at 0.6 MPa on the hydrophobic glass, dry at 20°C for 30 minutes, and complete the setting of the conductive silver layer 3;

[0071] (2) Spin-coat the base solution on the surface of the conductive silver layer 3 obtained in step (1), dry at 120° C. for 30 minutes, and complete the setting of the flexible base layer 1; the spin-coating speed is 600 r / min, and the spin-coating time is 60 s;

[0072] (3) The conductive silver layer 3 is spin-coated with the luminescent layer slurry on the surface of the flexible ...

Embodiment 2

[0081] This embodiment provides a figure 1 The low-voltage driven flexible light-emitting device shown includes a flexible base layer 1 and a light-emitting layer 2 disposed on the flexible base layer 1; conductive silver layers are respectively provided on both sides of the light-emitting layer 2 3.

[0082] The preparation method of the flexible light-emitting device driven by the low voltage comprises the following steps:

[0083] (1) Spray silver nanowire solution at 0.5MPa on hydrophobic glass, dry at 10°C for 40 minutes, and complete the setting of conductive silver layer 3;

[0084](2) Spin-coat the base solution on the surface of the conductive silver layer 3 obtained in step (1), dry at 110° C. for 40 min, and complete the setting of the flexible base layer 1; the spin-coating speed is 500 r / min, and the spin-coating time is 80 s;

[0085] (3) The conductive silver layer 3 is spin-coated with the luminescent layer slurry on the surface of the flexible base layer 1, ...

Embodiment 3

[0094] This embodiment provides a figure 1 The low-voltage driven flexible light-emitting device shown includes a flexible base layer 1 and a light-emitting layer 2 disposed on the flexible base layer 1; conductive silver layers are respectively provided on both sides of the light-emitting layer 2 3.

[0095] The preparation method of the flexible light-emitting device driven by the low voltage comprises the following steps:

[0096] (1) Spray silver nanowire solution at 0.8 MPa on the hydrophobic glass, dry at 30°C for 20 minutes, and complete the setting of the conductive silver layer 3;

[0097] (2) Spin-coat the substrate solution on the surface of the conductive silver layer 3 obtained in step (1), dry at 130°C for 20min, and complete the setting of the flexible substrate layer 1; the spin-coating speed is 800r / min, and the spin-coating time is 50s;

[0098] (3) The conductive silver layer 3 is spin-coated with the luminescent layer slurry on the surface of the flexible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com