Device and method for selecting nozzles in gas well testing

A technology for nozzles and gas wells, which is applied to the field of nozzle selection devices in gas well testing, can solve problems such as high personnel requirements, great influence of human factors, and inability to provide nozzle combinations, and achieves the effect of scientific selection methods and engineering requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

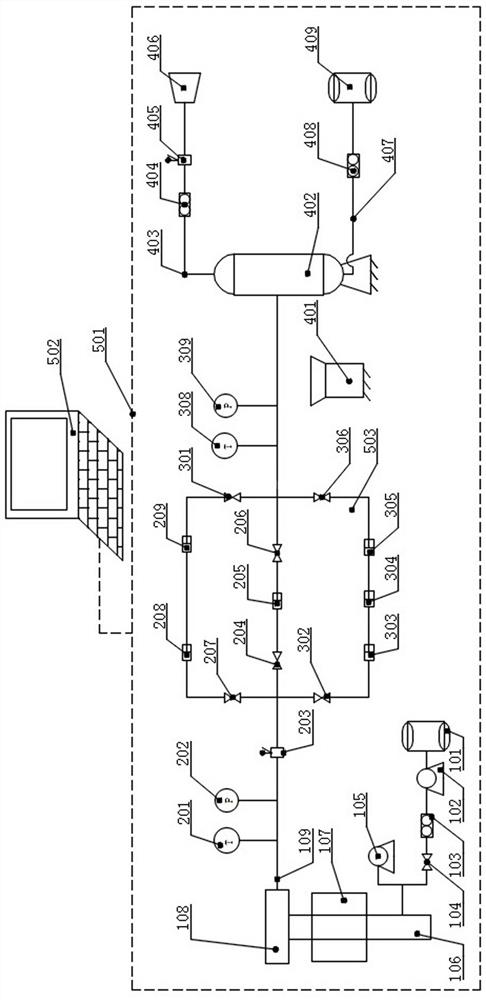

[0065] The present invention provides a fuel nozzle selection device in gas well testing, including a natural gas supply system, a gas well test multi-working condition simulation system, a fuel nozzle multi-combination testing system 503 and a control device; wherein,

[0066] The oil nozzle multi-combination testing system 503 includes various oil nozzle combinations arranged in parallel through pipelines;

[0067] The multi-working condition simulation system for gas well testing includes a surface flow pipeline 109, and the nozzle multi-combination testing system 503 is connected to the surface flow pipeline 109, and one end of the surface flow pipeline 109 is connected to a test string 106 , the test column 106 is connected with a vacuum pump 105; the other end of the surface flow pipeline 109 is connected with a gas-liquid two-phase separator 402; the gas outlet end of the gas-liquid two-phase separator 402 is connected with a gas flow A pipeline 403, the gas flow pipeli...

Embodiment 2

[0083] The method for selecting oil nozzles provided by the present invention using the oil nozzle selection device in the gas well test of the above-mentioned embodiment 1 includes the following steps

[0084] (1) Before the test starts, check the connection between the test pipe string 106 and other devices and check the sealing condition of the pipeline connection; use the vacuum pump 105 to pump the inside of the test pipe string 106 to a vacuum state, and turn off the vacuum pump 105; carry out the test of the first-level oil nozzle combination; Open the primary switch a204 and the primary switch b206, connect the pipelines of the primary nozzle combination, and close the pipelines of the secondary nozzle combination and the tertiary nozzle combination;

[0085] ① Open the intake valve 104 and the booster pump 102 to inject natural gas into the test pipe string 106 through the natural gas supply system and pressurize it, and monitor the pressure in the test pipe string 106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com