Hydraulic driving device applied to molded surface forming of wind tunnel nozzle

A driving device and surface forming technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of drive mechanism damage, small space size, processing, installation and motion errors, etc., to avoid Effects of destructive effects, improvement of driving ability, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

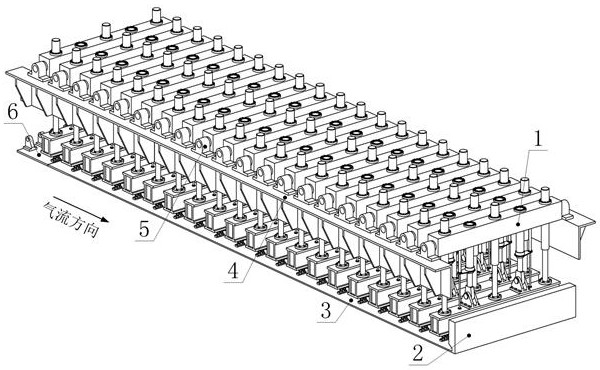

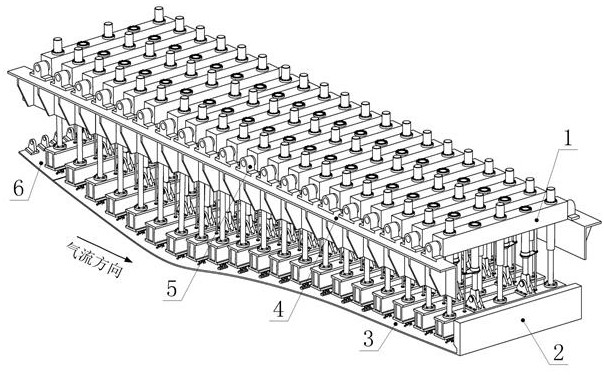

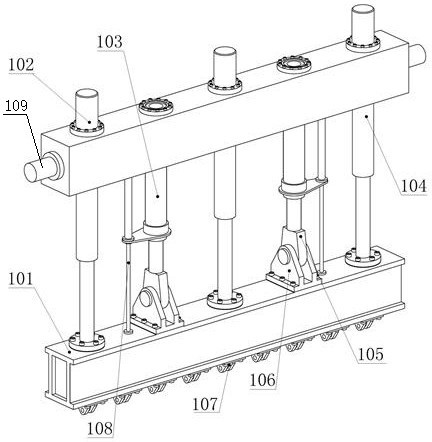

[0025] It can be seen from the drawings that in this embodiment, the profile of the wind tunnel nozzle includes a flex plate, a flex plate support frame, and a profile compensation mechanism; one end of the flex plate is connected to the flex plate support frame, and the other end of the flex plate is connected to the profile The compensation mechanism is connected; a support frame is set above the flex plate; several hydraulic drive devices connected with the flex plate are set on the support frame along the airflow direction; the hydraulic drive device includes an upper beam, a lower beam, a guide mechanism and a hydraulic drive mechanism; the guide The mechanism and the hydraulic drive mechanism are fixed on the upper beam and fixedly connected with the upper end surface of the lower beam.

[0026] A flexible plate hinge seat is provided on the upper end surface of the flexible plate; a flexible plate hinge is provided on the lower end surface of the lower beam; the flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com