Retainer for rolling bearing and rolling bearing

A technology of rolling bearings and cages, which is applied to bearing components, shafts, bearings, mechanical equipment, etc., can solve problems such as cage fracture, achieve the effect of ensuring support stability and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

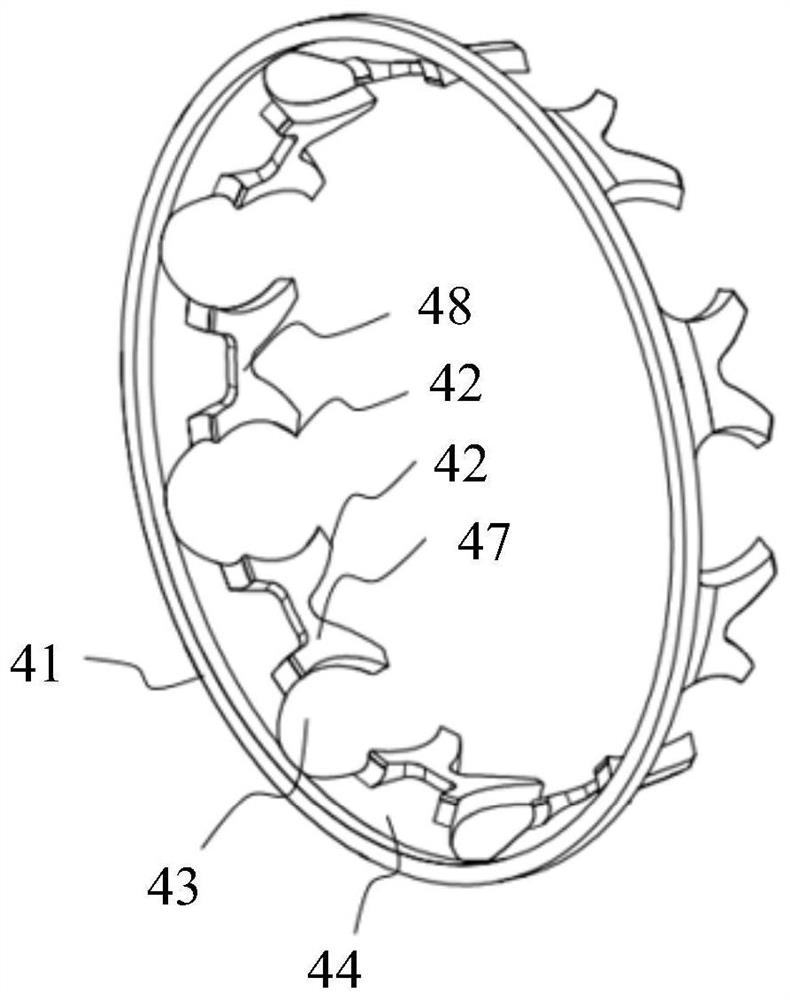

[0028] figure 1 A perspective partial sectional view of a rolling bearing according to a preferred embodiment is shown. Such as figure 1 As shown, the rolling bearing comprises an outer ring 2 and an inner ring 1 arranged coaxially and a row of rolling elements 3 arranged between the outer ring 2 and the inner ring 1 . The rolling bodies are here configured as balls 3 . The rolling bearing also includes a cage 4 integrally made of nylon material to isolate and guide the balls 3 .

[0029] The cage 4 according to the present embodiment consists of Figure 2 to Figure 5 show.

[0030] figure 2 with image 3Perspective views of the cage viewed from different viewing angles are shown. As shown in the figure, the cage 4 has a cage ring 41 and a cage beam protruding from an axial end face of the cage ring 41, the cage beam here having a substantially flat design and extending approximately in the axial direction of the bearing . A pocket 43 for accommodating the balls 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com