A manipulator device for power equipment maintenance

A technology for power equipment and manipulators, which is applied to manipulators, transmission devices, switch devices, etc., can solve the problems of inability to clamp and fix test clips, unfavorable test clips sent to high places to clamp power equipment, and inability to adapt to the use of test clips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

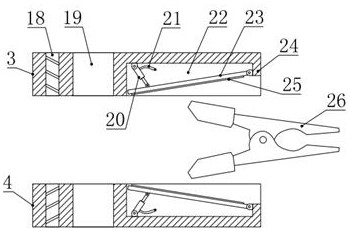

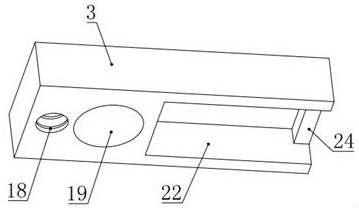

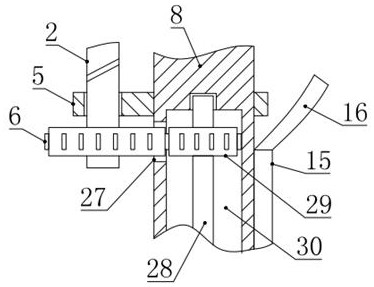

[0024] see Figure 1-4 , in an embodiment of the present invention, a manipulator device for power equipment maintenance includes an insulating rod 8, the upper part of the insulating rod 8 is provided with an upper splint 3 and a lower splint 4 for sliding, and the upper splint 3 and the lower splint 4 are vertical Arranged directly opposite to each other, a set of pneumatic adjustment splint assemblies are respectively installed on the opposite side of the upper splint 3 and the lower splint 4, and a control assembly for simultaneously controlling the two sets of pneumatic adjustment splint assemblies is installed on the lower part of the insulating rod 8. The side of the upper splint 3 and the lower splint 4 away from the pneumatic adjustment splint assembly is threadedly connected with a positive and negative threaded rod 2, and the upper end of the insulating rod 8 is equipped with an upper support plate 1 and a lower splint that is rotatably connected to the upper end of ...

Embodiment 2

[0027] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0028] In this embodiment, the upper splint 3 and the lower splint 4 are provided with a sliding hole 19 that is slidably connected with the insulating rod 8, and the upper splint 3 and the lower splint 4 are also provided with a threaded connection with the positive and negative threaded rod 2. Threaded hole 18; the transmission assembly includes an external transmission gear 6, a rotating ring 9, an insulating rotating rod 28 and an internal transmission gear 29, and the lower end of the positive and negative threaded rod 2 is fixed with an external transmission gear 6, and the external transmission gear 6 It is meshed with the internal transmission gear 29 provided in the insulating rod 8. A cavity 30 is provided in the insulating rod 8. The internal transmission gear 29 is located on the top of the cavity 30. The side wall of the insulating rod 8 is also provided with an external transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com