Computer hard disk gasket assembling equipment and method

A technology for computer hard disks and assembling equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as poor safety and low efficiency of rubber gaskets, improve safety, avoid palm damage, and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

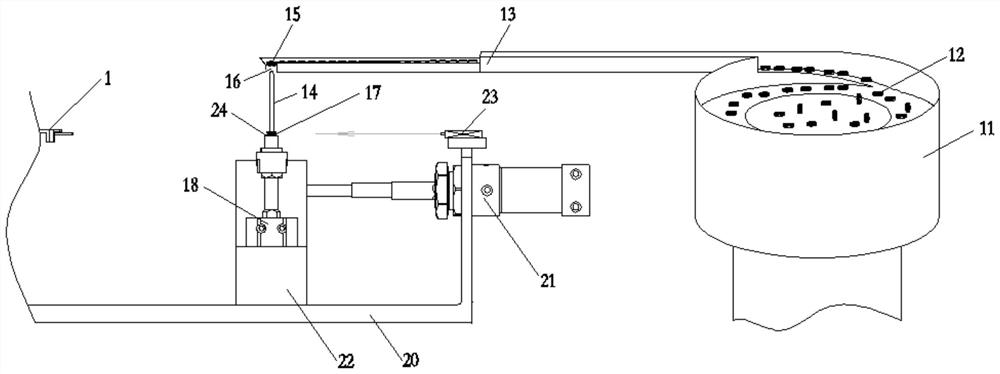

[0048] Such as image 3 As shown, a computer hard disk gasket assembly equipment includes a vibrating feeder 11. The vibrating feeder 11 belongs to existing common equipment and will not be described in detail here. The vibrating feeder 11 is provided with a gasket delivery track 13. A material guide port 16 is provided at the end of the gasket conveying track 13, the diameter of the material guide port 16 is 5mm larger than the outer diameter of the gasket, and the height of the material guide port 16 is equal to the thickness of the gasket. Directly below the material guide port 16 is vertically provided with a threading rod 14 with a stopper 24. The threading rod 14 is a solid rod made of stainless steel. The outer diameter of the threading rod 14 is smaller than the aperture of the washer. The lower part of 14 is fixedly connected to the telescopic rod of the vertical telescopic device 18, the driving part of the vertical telescopic device 18 is a stepping motor, and the d...

Embodiment 2

[0058] Such as Figure 4 As shown, a computer hard disk gasket assembly equipment includes a vibrating feeder 11. The vibrating feeder 11 belongs to existing common equipment and will not be described in detail here. The vibrating feeder 11 is provided with a gasket delivery track 13. A material guide port 16 is provided at the end of the gasket conveying track 13, the diameter of the material guide port 16 is 6 mm larger than the outer diameter of the gasket, and the height of the material guide port 16 is equal to the thickness of the gasket. Directly below the material guide port 16 is vertically provided with a threading rod 14 with a stopper 24. The threading rod 14 is a solid rod made of stainless steel. The outer diameter of the threading rod 14 is smaller than the aperture of the washer. The lower part of 14 is fixedly connected to the telescopic rod of the vertical telescopic device 18. The driving part of the vertical telescopic device 18 is a servo motor. After each...

Embodiment 3

[0068] Such as Figure 8 As shown, a computer hard disk gasket assembly equipment includes a vibration feeder 11, and a gasket delivery track 13 is arranged on the vibration feeder 11. A material guide port 16 is provided at the end of the gasket conveying track 13, the diameter of the material guide port 16 is 8mm larger than the outer diameter of the gasket, and the height of the material guide port 16 is equal to the thickness of the gasket. Directly below the material guide port 16 is vertically provided with a threading rod 14 with a limiter 24, the outer diameter of the threading rod 14 is smaller than the aperture of the washer, and the lower part of the threading rod 14 is fixedly connected to the telescopic rod of the vertical telescopic device 18 Above, the driving part of the vertical expander 18 is a servo motor. After each control action, the displacement of the expansion rod of the vertical expander 18 is just equal to the thickness of a rubber gasket. The vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com