Universal sorting equipment

A general-purpose, equipment technology, applied in sorting and other directions, can solve the problem of poor sorting effect of spherical materials, and achieve the effect of better conveying stability, good versatility and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

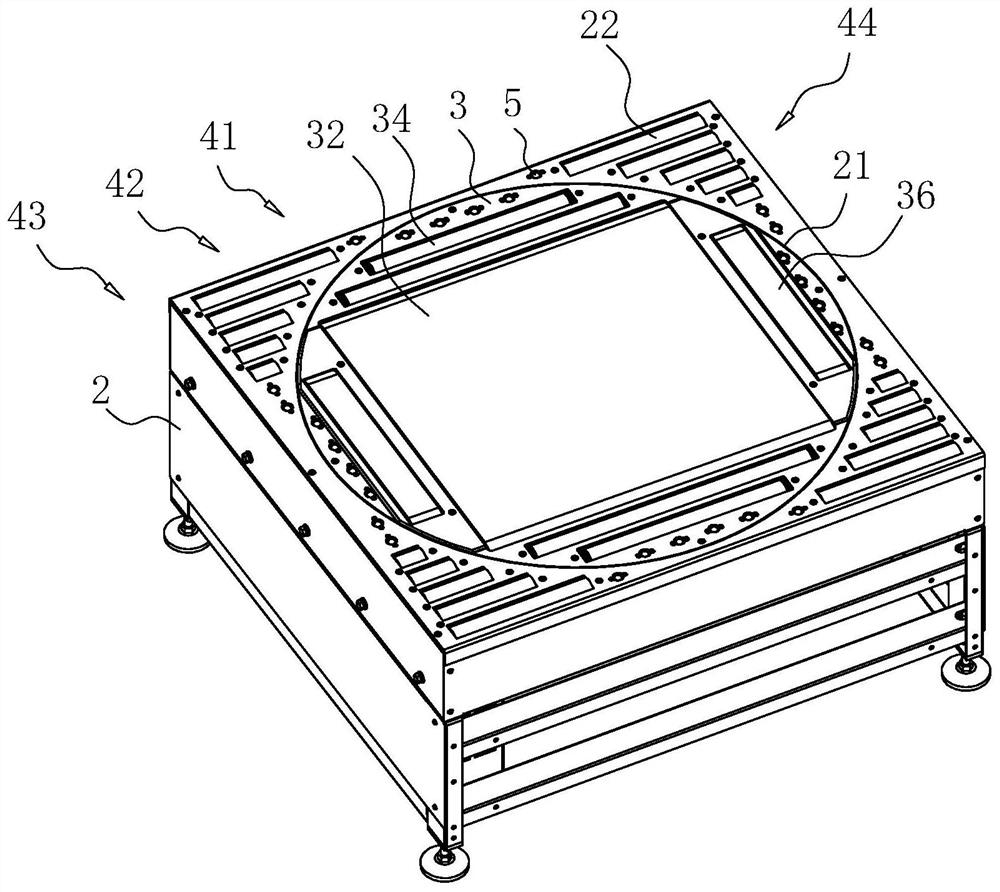

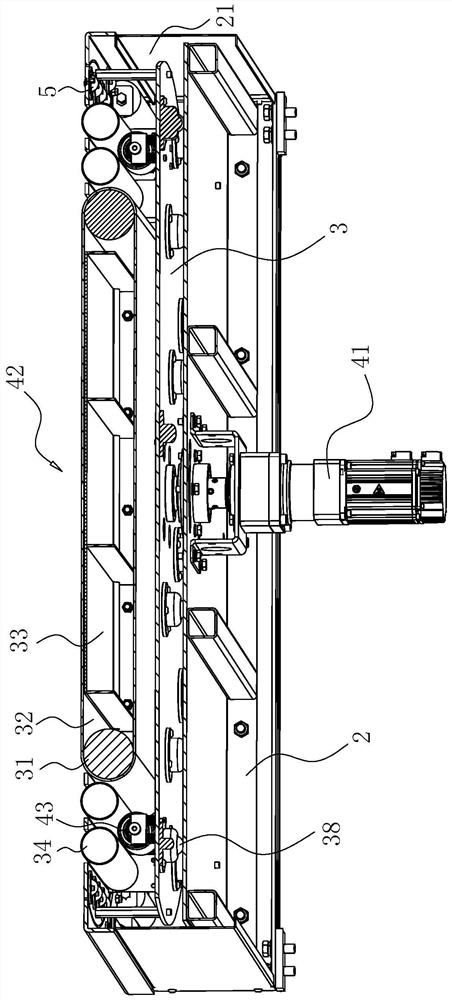

[0041] refer to figure 2 and 3, a general-purpose sorting device includes a square base 2, a circular support groove 21 is arranged on the top surface of the base 2, and a circular reversing table 3 is embedded in the gap of the support groove 21. The reversing table 3 is connected to the base 2 in rotation, and the base 2 is provided with a reversing mechanism 41 for controlling the rotation of the reversing table 3 . In order to facilitate the reversing table 3 rotation, the bottom surface of the reversing table 3 is scattered with a number of supporting universal balls 38. And rotate, effectively reduce the rotation resistance of the reversing table 3, improve the smoothness of the rotation of the reversing table 3. Two conveying rollers 31 are arranged horizontally on the reversing table 3 , the axes of the conveying rollers 31 are horizontal, and the arrangement direction of the conveying rollers 31 is perpendicular to the axial direction of the conveying rollers 31 . ...

Embodiment 2

[0051] refer to Figure 6 The difference between Embodiment 2 and Embodiment 1 is that four groups of grating obstacle sensors 6 are arranged around the base 2, and the number of the single group of grating obstacle sensors 6 is two and arranged oppositely. The four groups of grating obstacle sensors The object sensor 6 is arranged in sequence corresponding to the material input end and three material output ends of the abutment 2 . The grating obstacle sensor 6 is used to detect the moving direction of the material, and the grating obstacle sensor 6 is detachably and fixedly connected with the base 2 . The user can conveniently verify the movement direction of the material, and the grating obstacle sensor 6 is easy to disassemble and install, and easy to maintain.

[0052] refer to Figure 6 and 7 , the bottom end of the grating obstacle sensor 6 is provided with an extension block 61 , and the extension block 61 is glued and fixed on the side wall of the grating obstacle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com