A container bag and its automatic bagging system

A container bag, automatic technology, used in packaging, packaging machines, transportation and packaging, etc., can solve the problems of inability to meet the requirements of automatic loading of container bags, large bag body, complex structure, etc., to save production management costs, The effect of saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

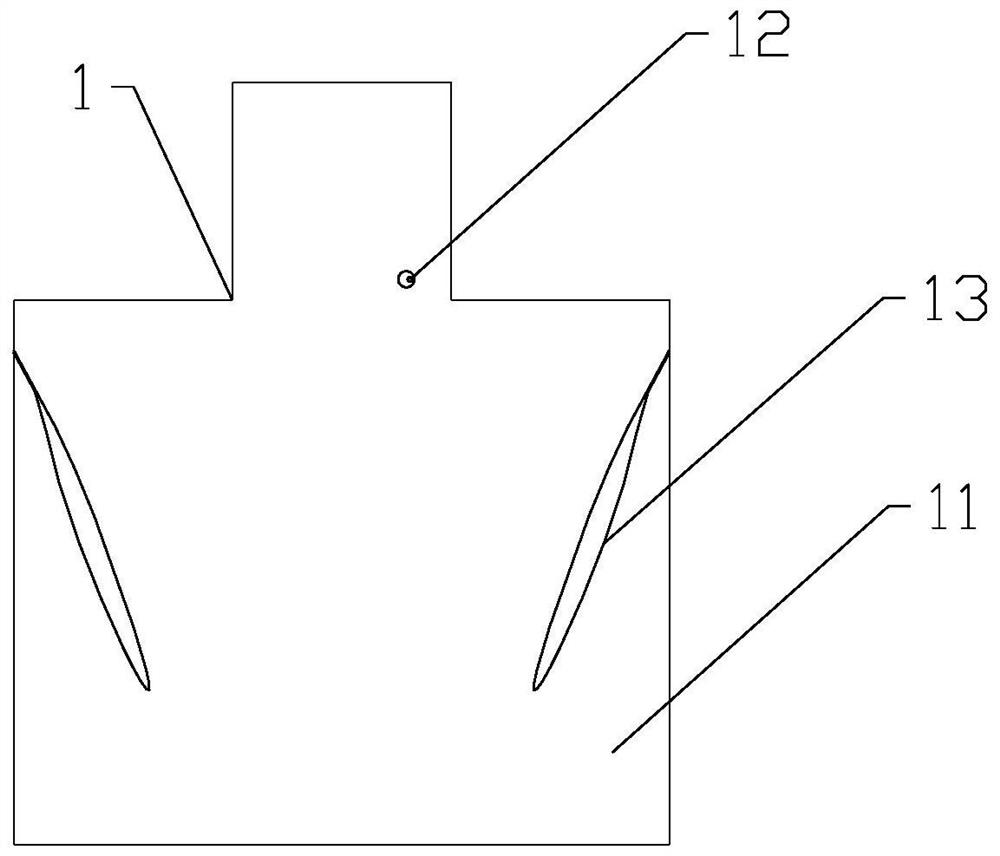

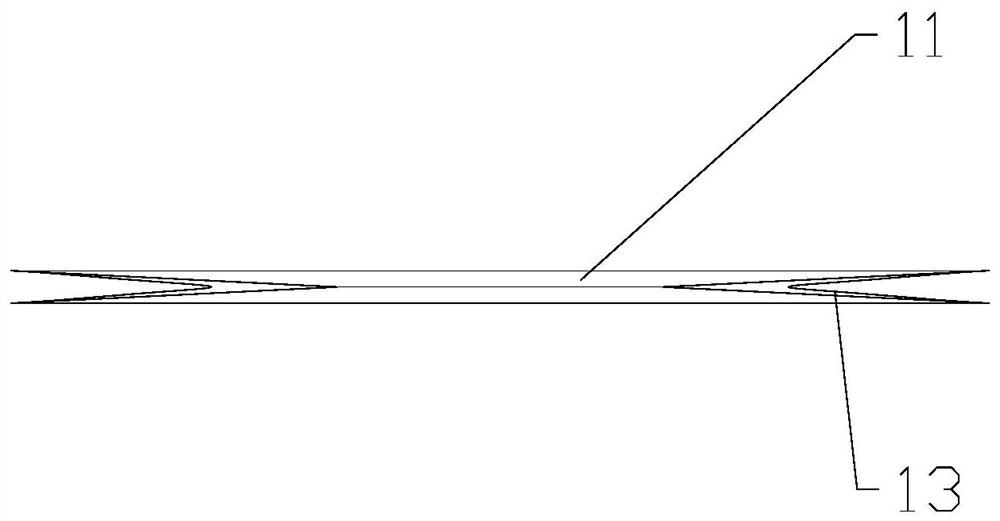

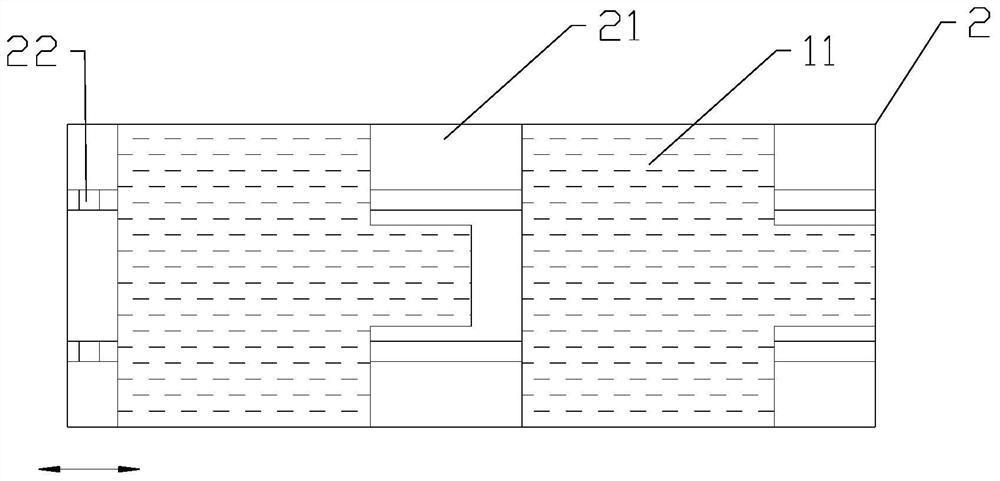

[0048] Please refer to figure 1, the present embodiment provides a container bag 1 and its automatic bagging system, which includes a container bag 1, a sling 13, a flat bed mechanism 2, a sorting and positioning mechanism 3, a clamping mechanism 4, grabbing and hooking Mechanism 5, the container bag 1 includes a woven bag 11, a moisture-proof cover film, and a one-way air release valve 12, and the sling 13 is connected to both sides of the woven bag 11 to form an overall bag shape. The flat bed mechanism 2 includes a flat plate 21, a push rod 22 and Sliding plate 23, sorting and positioning mechanism 3 comprises sorting suction cup 31, upper suction cup 32, lower suction cup 33, roller 34 and cylinder 35, and clamping mechanism 4 comprises mouthpiece bar 41, clamping bar 42, mouthpiece clip 43 and Pull bag suction cup 44, grasping and hook mechanism 5 include arm bar 51, telescopic arm 52, sling claw 53, sensor 54 and suspension hook 55; Container bag 1 is in the filling proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com