Personalized maxillofacial bone fracture plate based on 3D printing technology and manufacturing method thereof

A 3D printing and manufacturing method technology, applied in the field of medical devices, can solve the problems of high alloy strength, difficult bending of titanium plates, and difficulty in meeting the application in the field of oral and maxillofacial surgery, and achieve the effect of reducing costs and avoiding metal fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

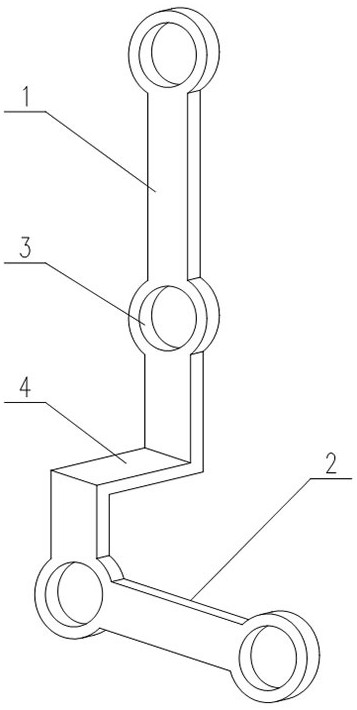

[0033] A personalized maxillofacial bone plate based on 3D printing technology, the personalized maxillofacial bone plate includes an upper bone plate 1, a connecting plate 4 and a lower bone plate 2 connected in sequence, one end of the upper bone plate 1 is connected to One end of the plate 4 is vertically connected, one end of the lower bone plate 2 is vertically connected to the other end of the connecting plate 4, and several fixing holes 3 are arranged on the upper bone plate 1 and the lower bone plate 2, so as to personalize the maxillofacial The bone plate becomes wider at the position where the fixing hole 3 is provided;

[0034] Wherein, the upper bone plate 1 can be one or more sequentially connected connecting units, the connecting unit includes a fixing plate and a matching plate, one end of the fixing plate is connected with the matching plate, and the matching plate is a circular plate, The fitting plate is provided with a fixing hole 3, the aperture of the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com