An electro-hydraulic emergency shutdown system and control method for testing process

A testing process and control method technology, applied in the field of oil and natural gas exploration and testing, can solve the problems of restricting the response time of the shutdown system, difficult testing operations, and high risks, so as to strengthen the comprehensive safety control capability, improve reliability and interactivity , the effect of improving the off-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0060] Different from the traditional control system that uses compressed air as the control signal, the present invention uses the current as the control signal and carries out the control logic design. Shutdown provides a new means of control.

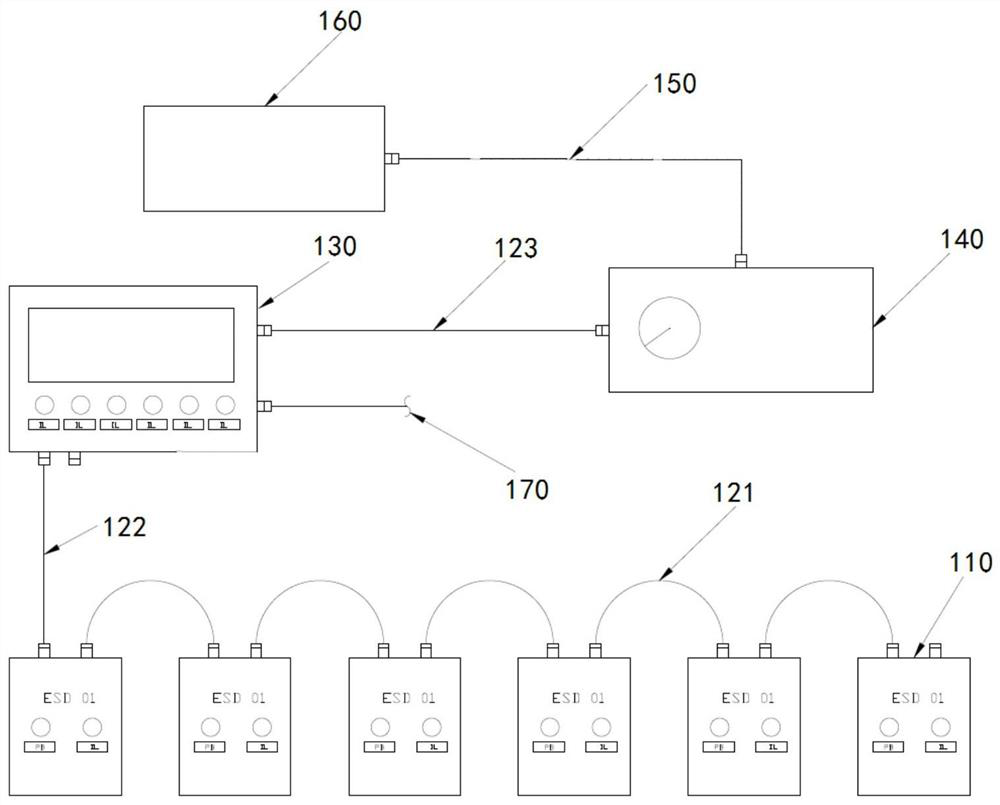

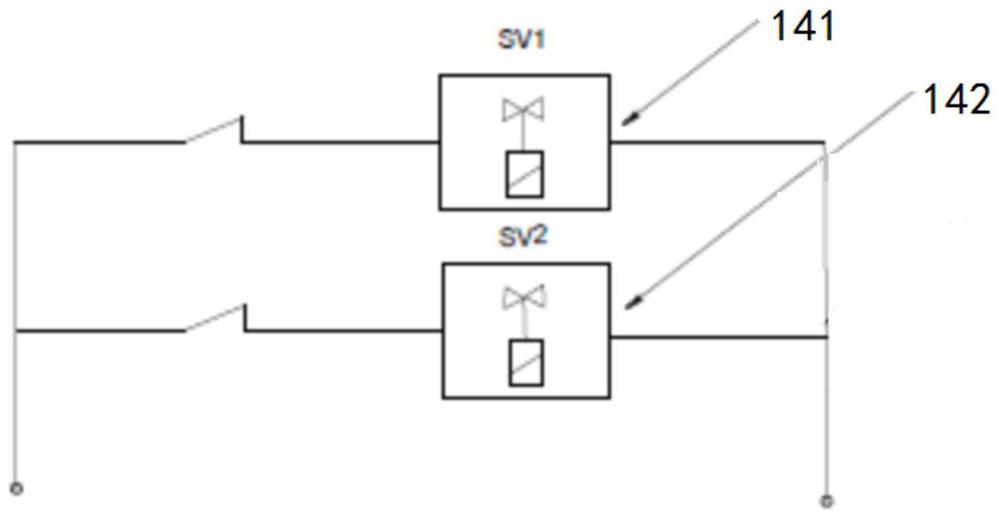

[0061] like figure 1As shown, the present invention provides an electro-hydraulic emergency shutdown system for a testing process, including: a plurality of remote control button boxes 110, a first multi-core cable 121, a second multi-core cable 122, a third multi-core cable The cable 123, the electric control panel 130, the solenoid valve box 140, the induction gas line 150, the hydraulic control panel 160 and the data communication interface 170, wherein the connection sequence of the plurality of remote control button boxes 110 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com