Misassembly preventive system for electrical product assembly

An error-proofing system and technology for electrical products, applied in the field of error-proofing systems, can solve the problems of slow image data speed, small structure of electronic components, and high requirements for component size, and achieve the effect of reducing the possibility of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

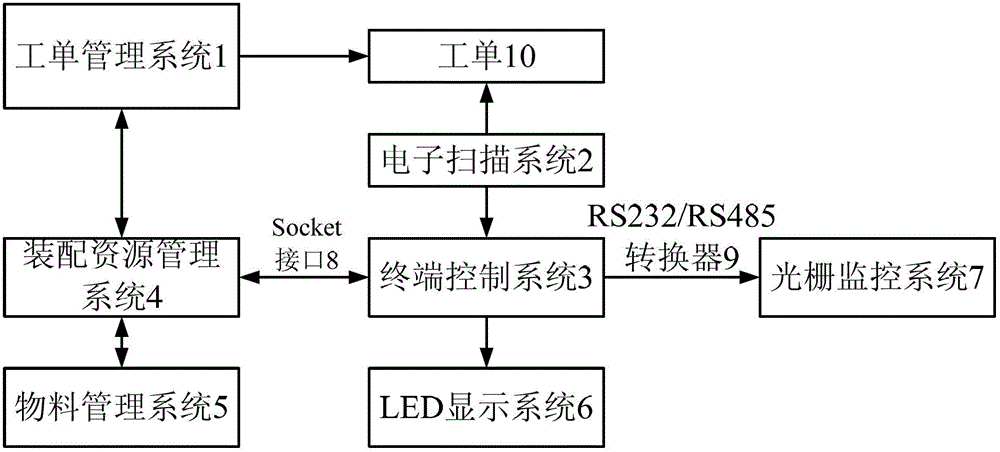

[0017] Such as figure 1 As shown, an anti-wrong assembly system for electrical product assembly includes: work order management system 1, electronic scanning system 2, terminal control system 3, assembly resource management system 4, material management system 5, LED display system 6 and grating monitoring System 7, wherein: the work order management system 1 generates and prints the work order 10 according to the assembly plan, and the electronic scanning system 2 is installed on the station of the assembly line to scan the barcode information on the work order 10 and send it to the terminal control system 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com