High-pressure ball valve

A high-pressure ball valve and valve body technology, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., to improve sealing performance, facilitate stable installation, and reduce frictional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

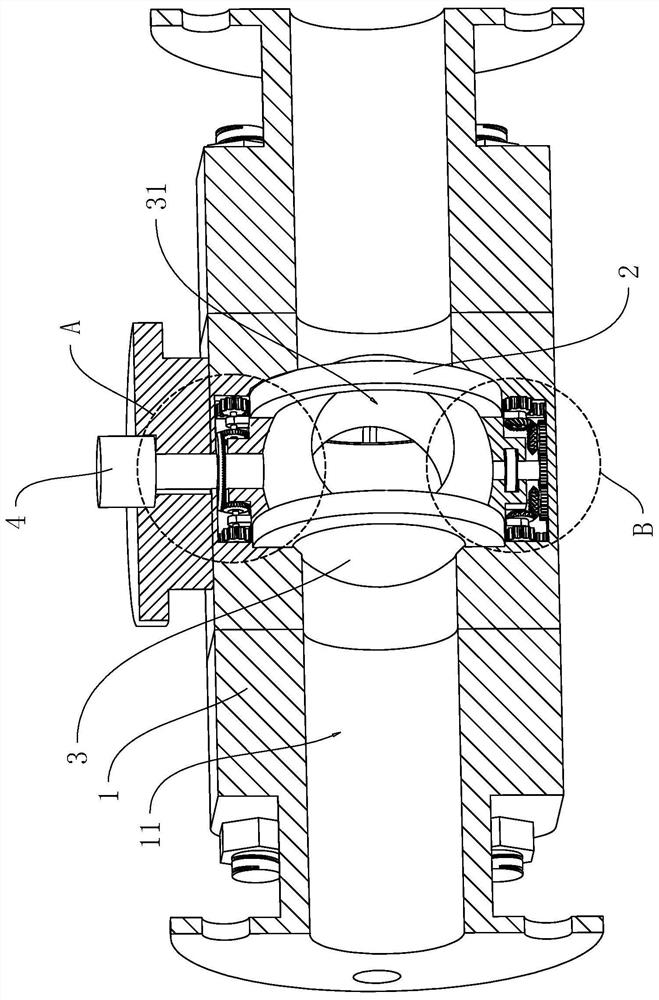

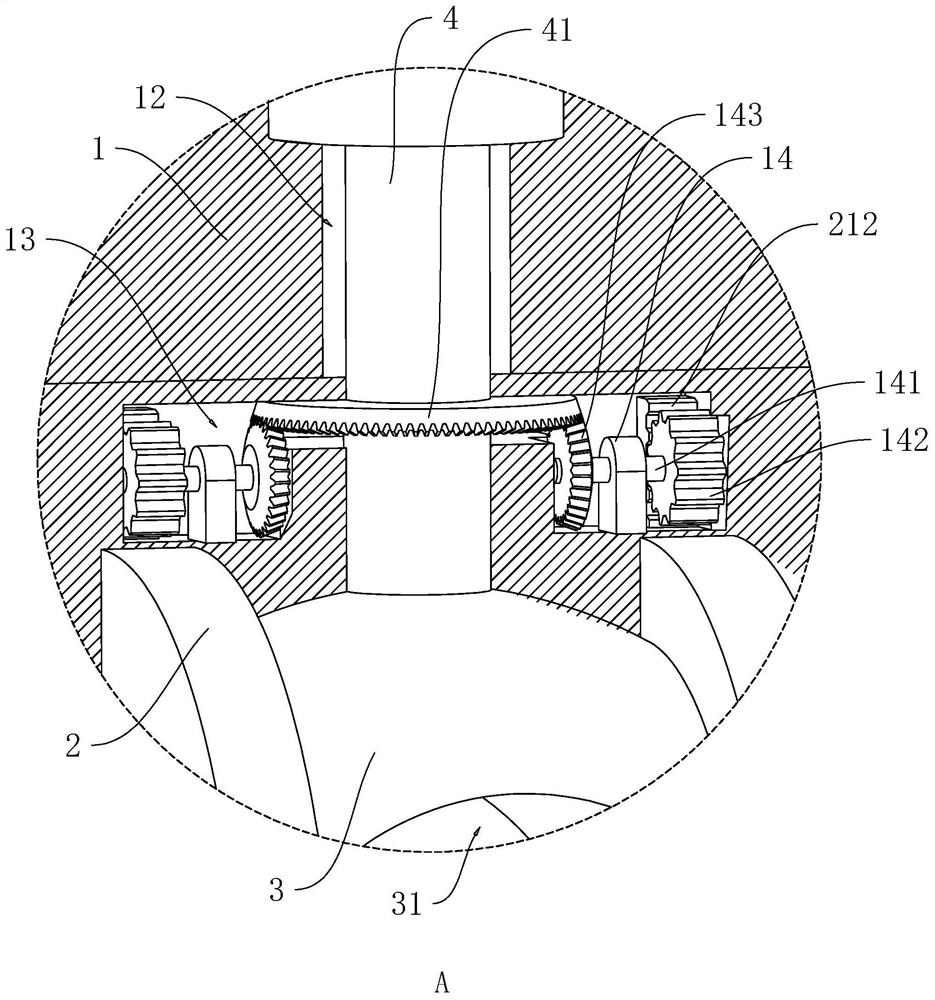

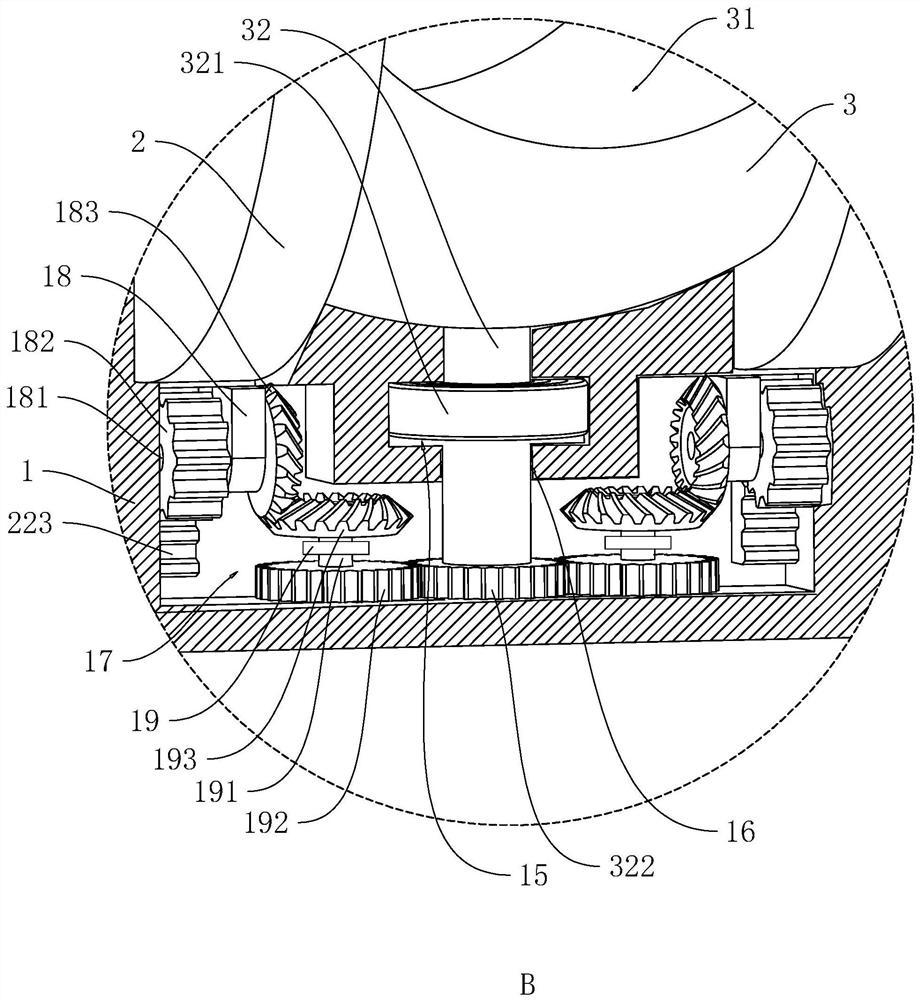

[0037] The following is attached Figure 1-4 The application is described in further detail.

[0038] The embodiment of the present application discloses a high-pressure ball valve. refer to figure 1 with figure 2 , the high-pressure ball valve includes a valve body 1, and both ends of the valve body 1 are provided with pipes 11, and the two pipes 11 are fixedly connected with the external water inlet pipe and the water outlet pipe through flanges, so that the fluid in the external water inlet pipe can be Stay in the water outlet pipe along the pipeline 11 of the valve body 1.

[0039] A valve ball 3 is rotatably connected to the inside of the valve body 1, and a valve stem 4 is fixedly installed on the top of the valve ball 3, and the end of the valve stem 4 away from the valve ball 3 stretches out of the valve body 1, and on the top of the valve ball 3 The valve body 1 is also provided with a rotating hole 12 communicating with the two pipelines 11, and the rotating hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com