Automatic boxing and packaging equipment for blocky products

A technology of automatic boxing and packaging equipment, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of error-prone, low efficiency, and uneven packaging quality, and achieve the effect of facilitating automatic packaging and avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

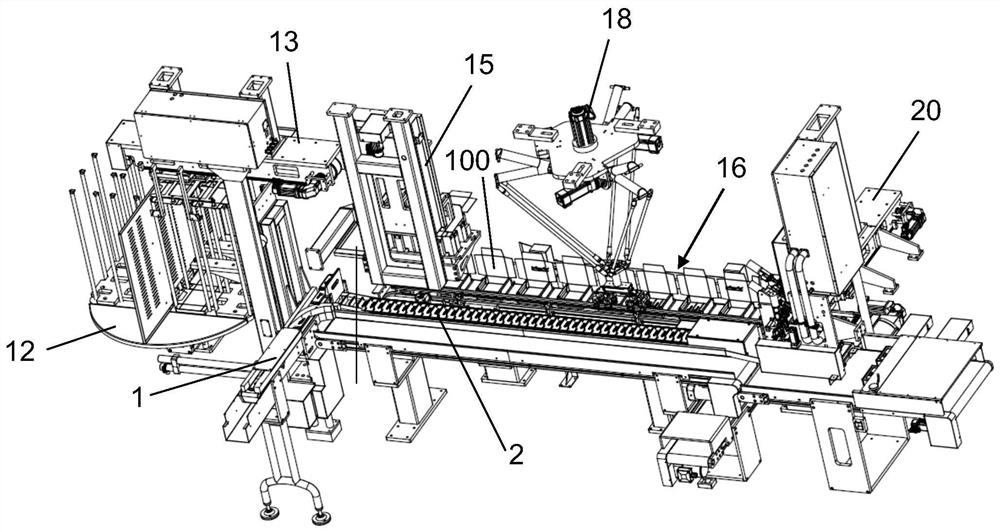

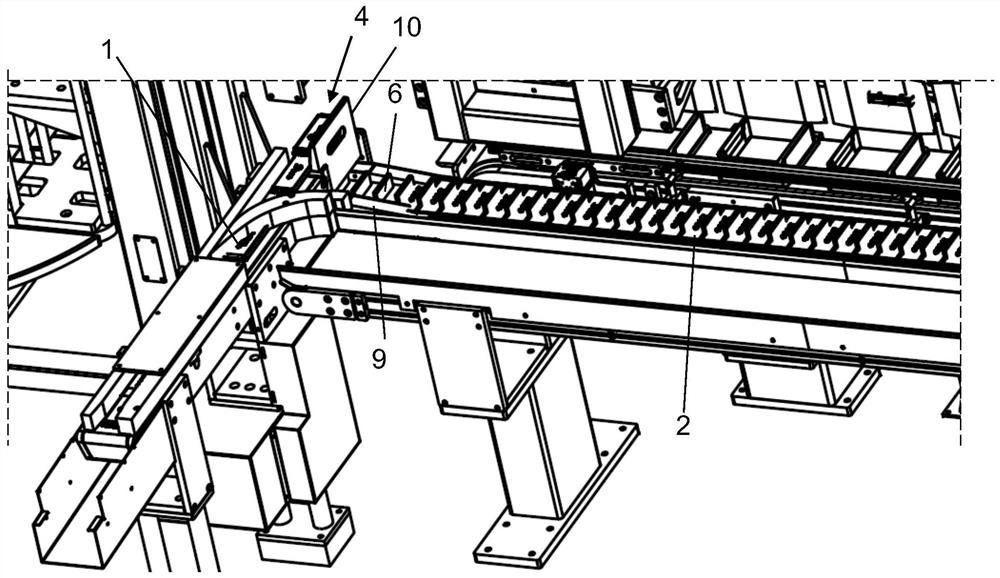

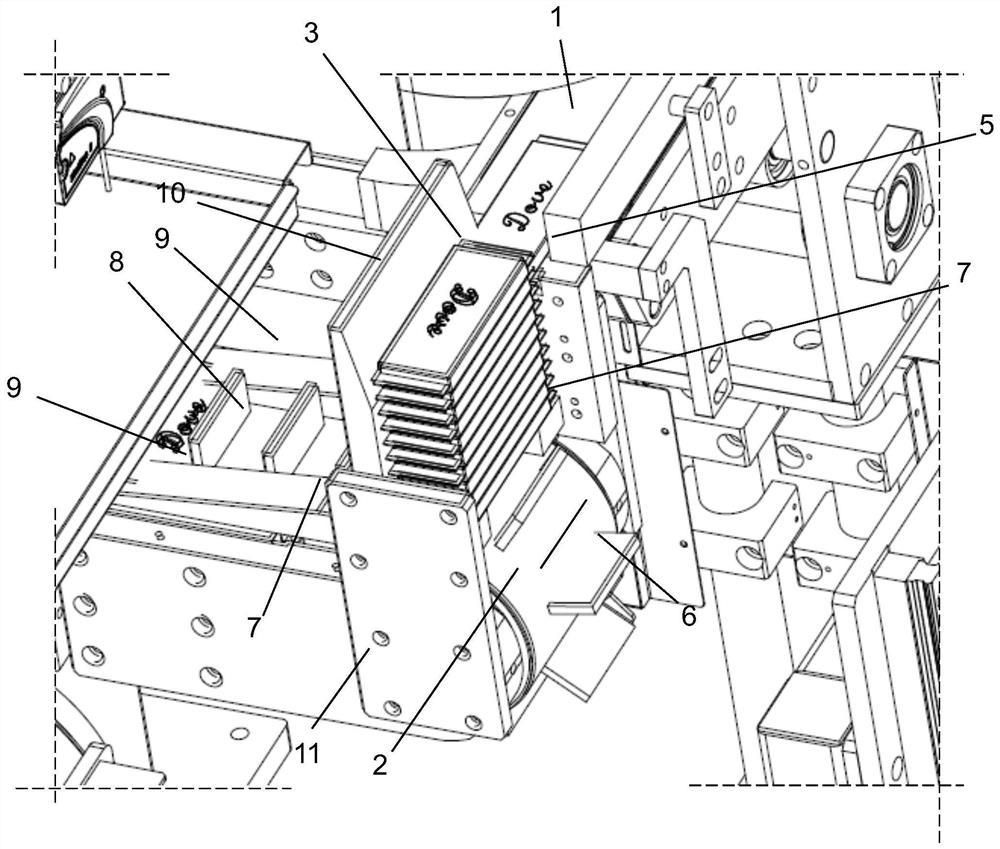

[0044] The automatic box packing equipment of block product of the present invention is as Figure 1 ~ Figure 3 As shown, it mainly includes a feeding conveyor belt 1 and a sorting conveyor belt 2 arranged horizontally and vertically. The feeding conveyor belt 1 is used to transport block products such as chocolate before packaging. They are transported vertically and sequentially (the products 3 are arranged adjacently in the width direction), and the end of the feeding conveyor belt 1 is provided with a product stacking bin 4 above the sorting conveyor belt 2 . Baffles 6 are arranged at intervals on the sorting conveyor belt 2 , and accommodating chambers 8 matching the products 3 are formed between the baffles 6 . The lower part of the silo 4 is fixed with a support step 7 for the product 3, the top of the support step 7 is plane and higher than the finishing conveyor belt 2 and lower than the baffle plate 6, and the baffle plate 6 is lower than the lowermost piece on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com