Squeezing and filtering mechanism for raspberry wine brewing

A technology of extrusion filtration and raspberry, which is applied in the field of extrusion filtration mechanism for raspberry wine making, can solve the problems of fruit juice turbidity, poor quality and taste, low filtration retention efficiency, etc., and achieve the effect of sufficient extrusion filtration and not easy to block materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

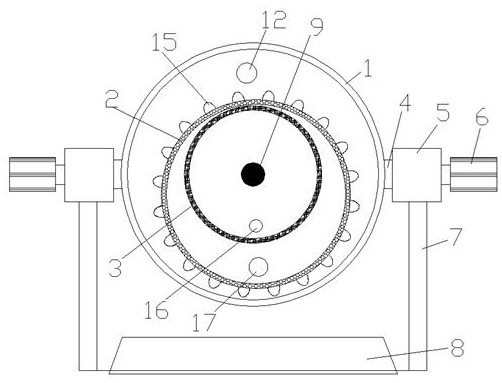

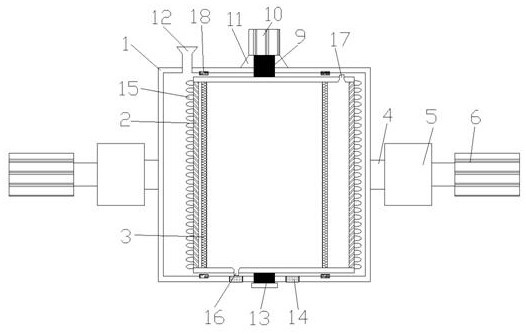

[0036] Refer Figure 1-2A raspberry brewed is used as an extrusion filter mechanism including a torrel 1, and the eccentric cartridge 2 provided in the flip cylinder 1 and the liquid barrel 3 disposed in the eccentric tube 2, and the middle portion of the outer arc surface of the flip cylinder is configured. The two flip shafts 4, the two flip shafts 4 are arranged horizontally, and the two flip shafts 4 are connected to the flip cylinder 1 axis, and the flip shaft 4 is connected to one end of the pot body 1 is connected in the gearbox 5. On the output gear, the input gear within the replacement box 5 is connected to the active shaft of the flip drive motor 6, and the bottom of the replacement case 5 is connected at the top end portion of the U-shaped frame 7, and the upper surface of the U-shaped frame 7 is fixed. There is a collection box 8, and the collection box 8 opens from the middle of the two flip shafts 4; the center of the turbine 1 is attached to the axial hole activity,...

Embodiment 2

[0042] According to a raspberry brewing extrusion filter mechanism according to Example 1, the present invention also implements a raspberry clarified juice, which includes the following steps:

[0043] S1, test: According to the structure of claim 1, the made of flip cylinder 1 is mounted in place, the test flip shaft 4 rotation speed, the flip cylinder 1 rotation and sealing conditions;

[0044] S2, feed, eccentric extrusion: open material strip 12, add raspberry fruit and fill the cavity between the flip cylinder 1 and the ejection 2, open the flip drive motor 6, so that the flip shaft 4 rotation is 10-14R / MIN, cause the fruit to move in the direction of the tunnel 1 axis, and thereby increasing the friction between the conical bumps 15, improving the efficiency of the broken peel juice;

[0045] The rotary drive motor 10 is opened so that the rotating shaft 9 rotational speed reaches 300-500 r / min, and the extrusion between the inner wall of the inner wall of the tunnel 1 ...

Embodiment 3

[0051] In order to further optimize the effects of the present invention, the present embodiment also limits the minimum distance between the outer wall of the liquid barrel 3 in Example 1 and the inner wall of the eccentric tube 2, that is, objectively forms the eccentric cartridge 2 and the tap tube 1. The liquid cartridge 3 is tangent with the eccentric cartridge 2 and the flip cylinder 1 is concentrically disposed with the liquid barrel 3, forming two bladder cavities, the outer bladder cavity for extrusion and once filtration The internal bladder cavity is used for secondary filtration;

[0052] Further, there is a heating plate in the inner arc surface in the flip cylinder 1 for heating; alcohol and sugar can also be added to the material strip 12, and the sealed flush cartridge 1 can be directly used as a fermentation place, which can be used directly for simple rough The brewing equipment uses fermentation to promote extrusion pulverization effect, and extruded pulverizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com