Moving mechanism of 3D printing nozzle and printer with moving mechanism

A 3D printing and moving mechanism technology, applied in mechanical equipment, coating devices, processing drive devices, etc., can solve the problems of printing nozzle vibration, affecting the printing effect, unstable printing process, etc., to improve stability, reduce Orbital tremor effects, effects that reduce the chance of appearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

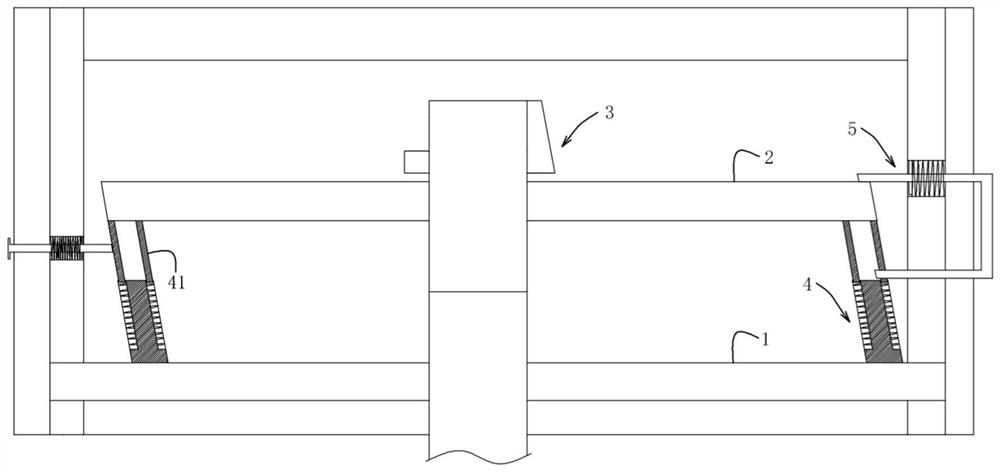

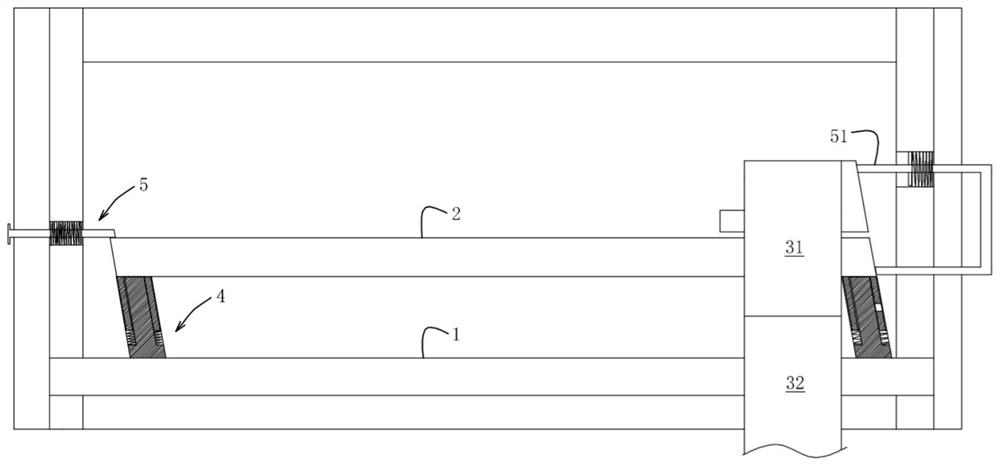

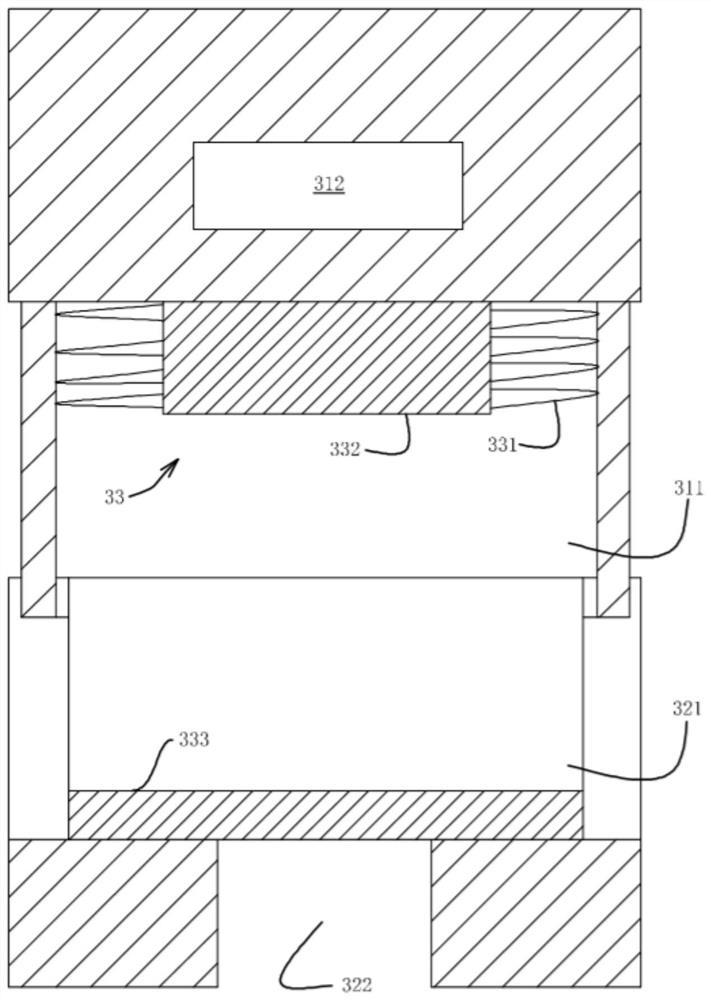

[0023] A moving mechanism for a 3D printing nozzle, comprising a first sliding track 1 and a shock-absorbing auxiliary track 2 arranged on the upper end of the first sliding track 1 and movable relative to the first sliding track 1, and also includes a 1 and the driving device 3 on the shock-absorbing auxiliary track 2 for controlling the movement of the 3D printing nozzle, wherein a gap is provided between the first sliding track 1 and the shock-absorbing auxiliary track 2, and the driving device 3 includes a sliding arrangement on the shock-absorbing auxiliary The first driving device 31 on the track 2 and the second driving device 32 vertically slidingly connected with the first driving device 31, when the driving device 3 slides to the rightmost end of the shock-absorbing auxiliary track 2, the shock-absorbing auxiliary track 2 drives the second driving device 32. A driving device 31 slides obliquely to the right and down relative to the first sliding track 1. When the driv...

Embodiment 2

[0028] A 3D printer, comprising the moving mechanism of the 3D printing nozzle described in Embodiment 1.

[0029] The principle of use of the present invention: the purpose of the moving mechanism of the 3D printing nozzle of the present invention is to reduce the tremor of the rail during the process of driving the 3D printing nozzle to reciprocate and print through the cooperation of the shock-absorbing auxiliary rail 2 and the first sliding rail 1 , so as to reduce the probability of printing ripples and improve the stability of printing;

[0030] During use, when the driving device 3 slides to the right and approaches the rightmost end of the auxiliary shock-absorbing track 2, the outer end surface of the first driving device 31 collides with the upper end of the elastic limit rod I51 and pushes the elastic limit rod I51 to the right Move until the lower end of the elastic limit rod I51 breaks away from the inner wall of the limit cylinder 41 located at the right end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com