Pipe fitting forming machining method and device for pre-welded bifurcated branch pipes

A bifurcated branch pipe and forming processing technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of poor weld quality and inability to complete welding, optimize the forming process, save the difficulty of welding complex shapes, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with specific embodiments.

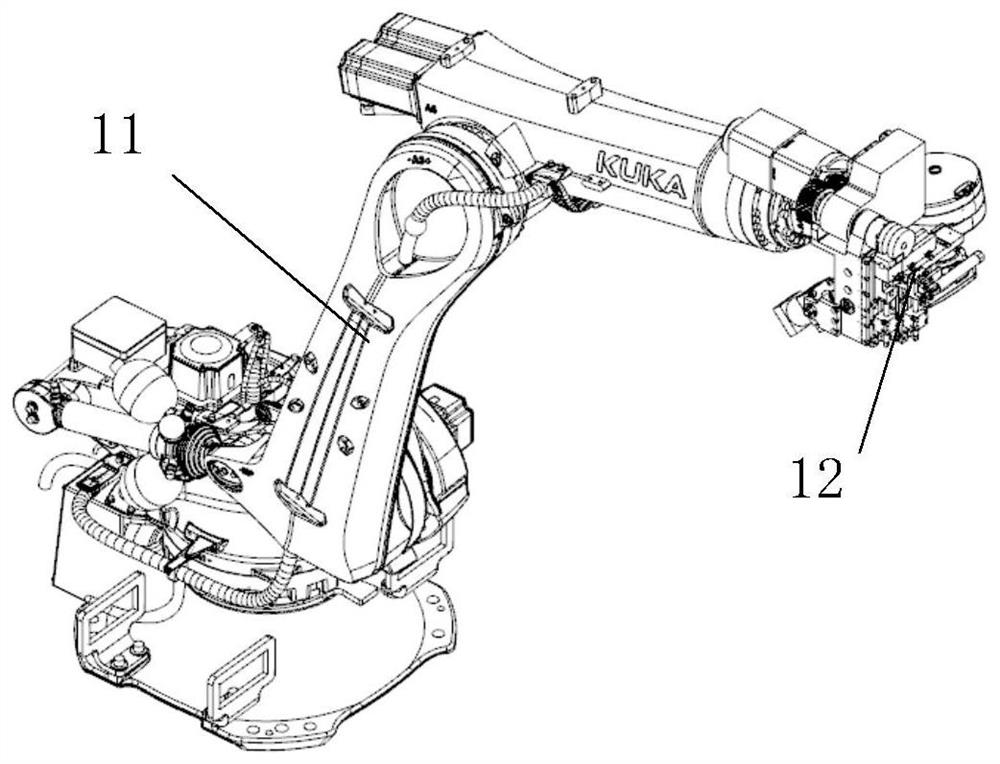

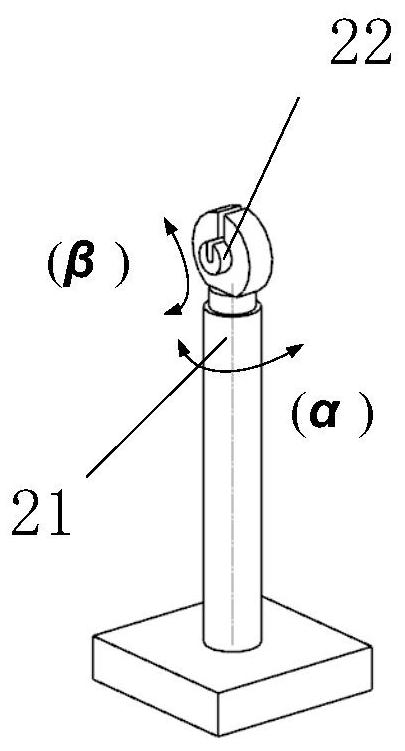

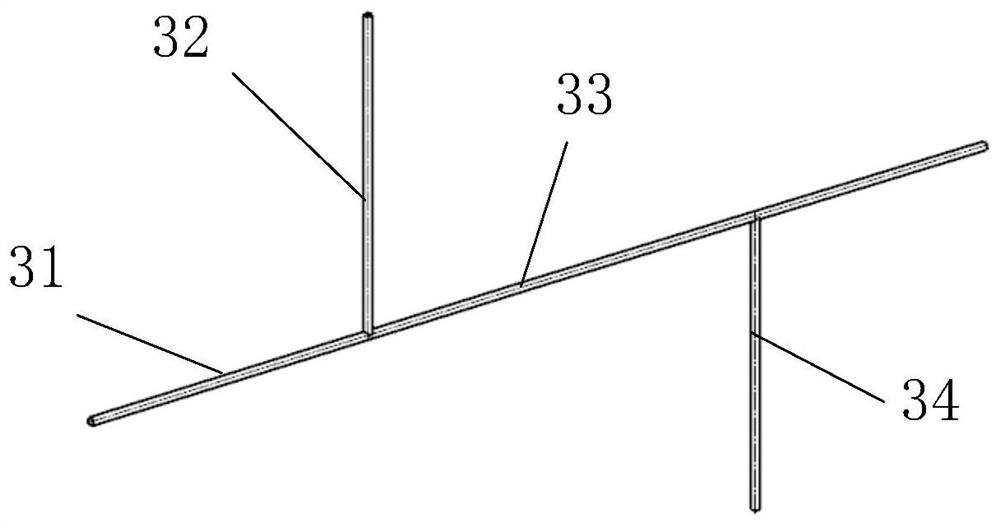

[0039] figure 1 It is a structural schematic diagram of a pipe bending robot in the present invention, figure 2 It is a structural schematic diagram of the clamping and rotating device in the present invention, image 3 It is a structural schematic diagram of the tube blank to be formed in the present invention, Figure 4 It is a schematic diagram of the pipe bending robot clamping the pipe blank in the present invention, Figure 5 It is a schematic diagram of the bending forming of the first part of the main pipe in the present invention, Figure 6 It is a schematic diagram of the position and posture adjustment of the first branch pipe to be bent in the present invention, Figure 7 It is a schematic diagram of the bending and forming of the first branch pipe in the present invention, Figure 8 It is a schematic diagram of the position and attitude adjustment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com