Quick sorting system and method for retired power batteries

A sorting system and power battery technology, applied in sorting and other directions, can solve the problems of reducing the available energy of battery packs, decommissioned battery packs cannot be directly matched with energy storage systems, and there are potential safety hazards, so as to achieve a small error in data testing accuracy. , The sorting method is simple and convenient, and the test time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

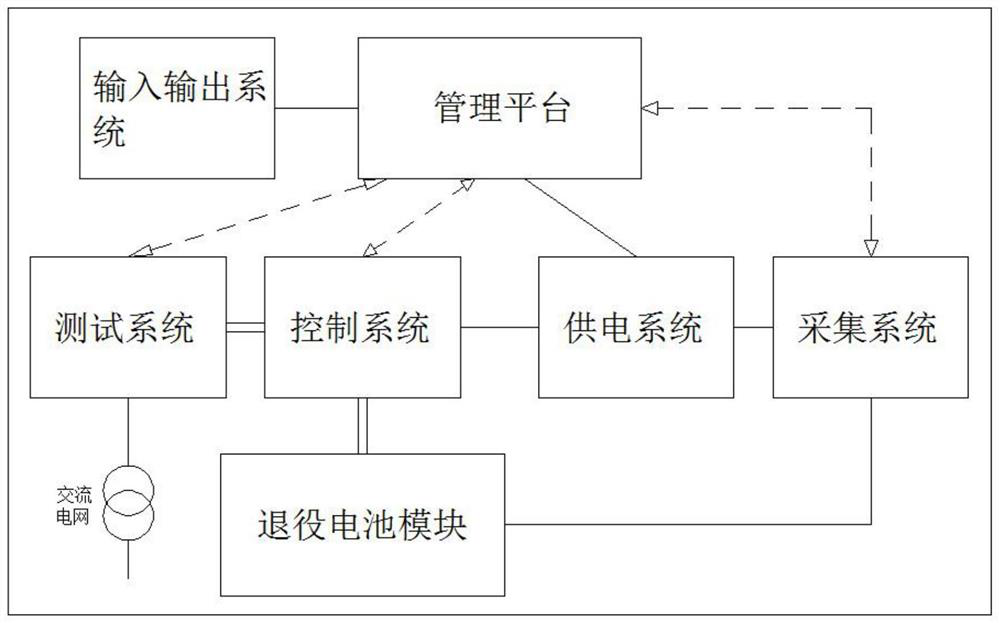

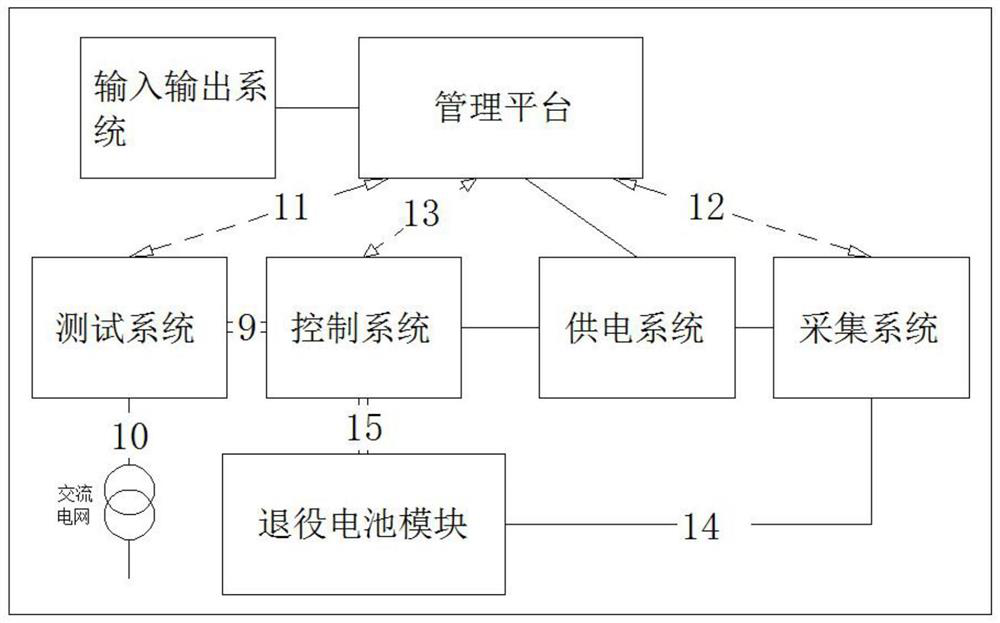

[0052] see image 3 , taking AC220V / 10kW sorting system for sorting retired 12.8V200Ah battery modules of BYD E6 models as an example.

[0053] Sorting system structure see image 3 , including a management platform, a test system, an acquisition system, a control system, an input and output system, a power supply system, an AC grid, and a decommissioned battery module, wherein the management platform is connected to the test system, the acquisition system, and the control system through communication lines 11, 12, and 13, respectively. System connection; the first end of the test system is connected to the control system through the DC power line 9, the second end is connected to the AC power grid through the AC power line 10, and communicates with the management platform through the communication line 11; the acquisition system communicates with the decommissioned battery through the acquisition harness 14 The modules are connected, and also connected to the management plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com