High-flux material synthesis equipment and method based on micro-fluidic chip

A technology of microfluidic chips and synthesis equipment, which is applied in chemical instruments and methods, feeding devices, control/regulation processes, etc., can solve the problems of poor material repeatability, low accuracy and controllability of reaction parameters, and low research efficiency, etc. Achieve the effect of improving the preparation accuracy, reliable microfluidic high-throughput synthesis and detection process, and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

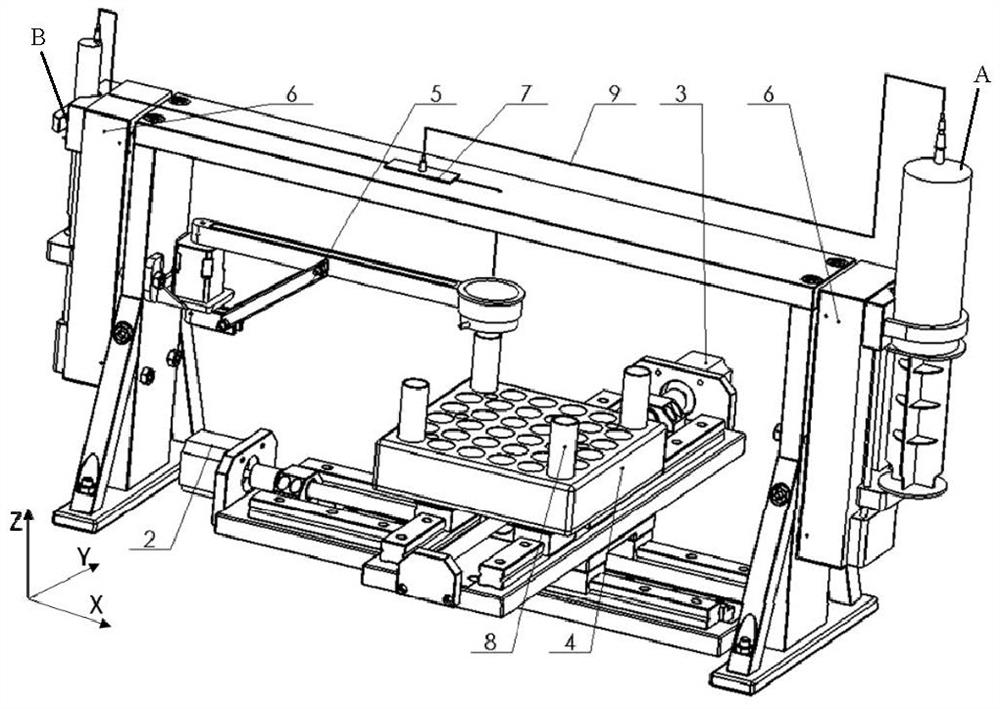

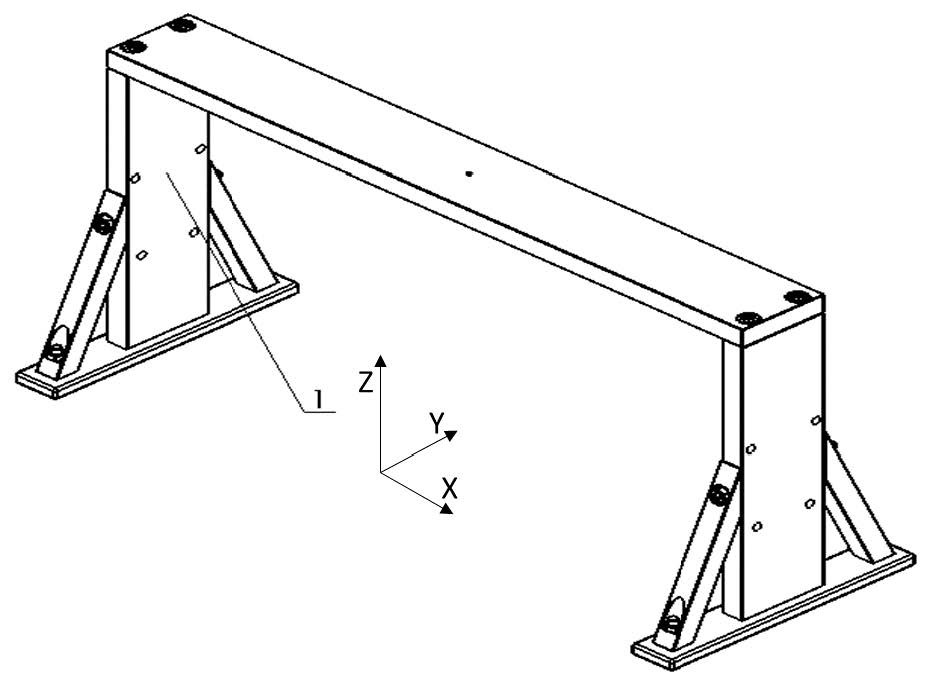

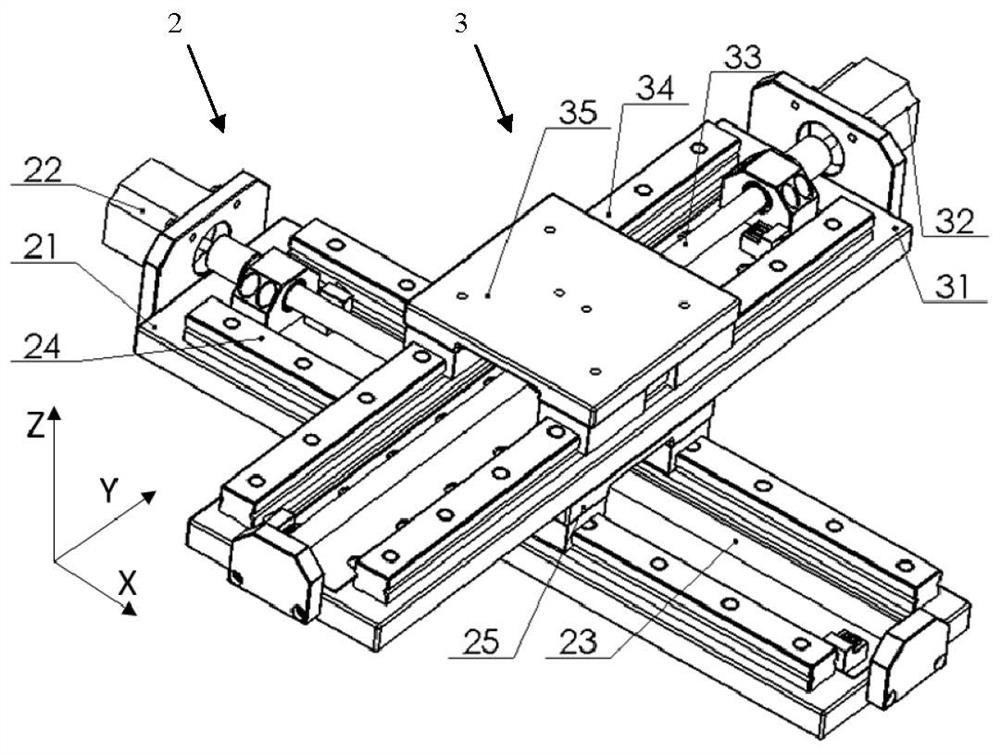

[0052] A high-throughput material synthesis device based on a microfluidic chip is provided here. figure 1 It is a schematic diagram of the overall structure of a high-throughput material synthesis device according to an embodiment of the present invention. The following will figure 1 The left-right direction when the middle face is viewed towards the gantry support 1 is defined as the first axis direction, that is, the X-axis direction, and the front-rear direction that is orthogonal to the X-axis direction in the horizontal plane is defined as the second axis direction, that is, the Y-axis direction, and the orthogonal The up and down vertical extension direction of the horizontal plane fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com