High-internal-phase Pickering emulsion, preparation method and application thereof, and mayonnaise containing high-internal-phase Pickering emulsion

A Pickering emulsion, high internal phase technology, applied in the field of food processing, can solve problems such as low density lipoprotein, and achieve the effects of simple operation, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

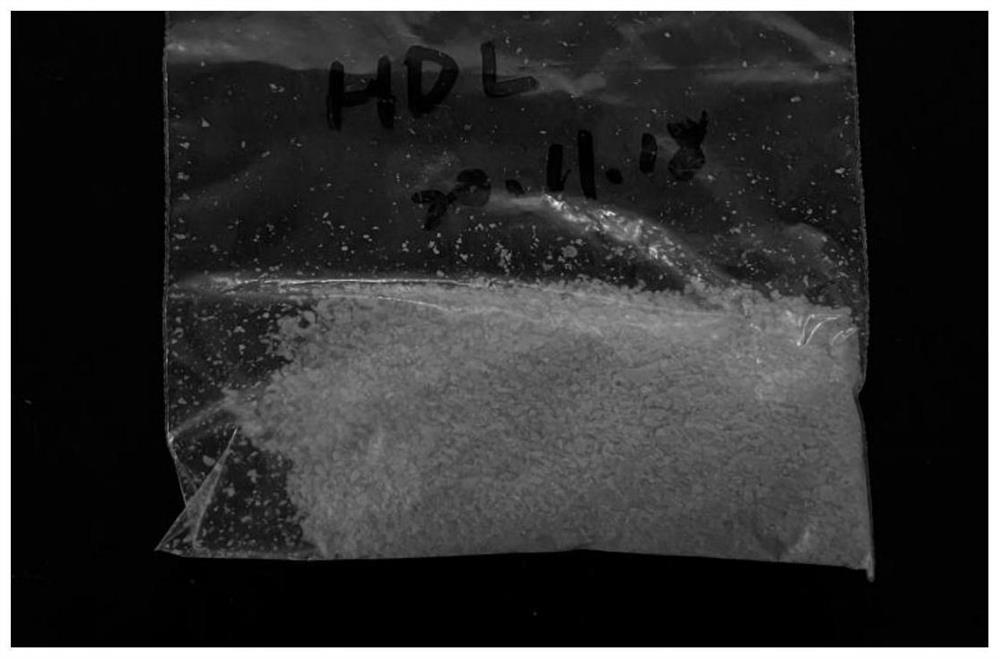

[0030] In the present invention, the preparation method of the high-density lipoprotein particles derived from egg yolk preferably comprises the following steps:

[0031] Mix egg yolk particles with water, heat in a water bath at 60-70°C, let stand and separate layers, remove upper layer floating matter, collect lower layer precipitates, and dry the lower layer precipitates to obtain egg yolk-derived high-density lipoprotein particles. In the present invention, the mass ratio of the egg yolk particles to water is preferably (0.5-1.5):(0.5-1.5), more preferably 1:1. In the present invention, the temperature of the water bath heating is preferably 65° C., and the time of the water bath heating is preferably 2 hours to 6 hours. In the present invention, the drying method is preferably freeze drying, and the drying time is preferably 24 hours. In the present invention, the egg yolk granules are preferably prepared by conventional preparation methods in the art. During the specifi...

Embodiment 1

[0042] 1. Preparation of egg yolk granules (hen egg granules):

[0043]Open the egg and carefully remove the yolk, then roll the complete yolk on the filter paper to absorb the remaining egg white, and then remove the yolk band with tweezers. Egg yolk was mixed with an equal amount of 0.16M NaCl solution, and mixed with a magnetic stirrer for 30 minutes to obtain diluted egg yolk liquid. Centrifuge at 8000 rpm for 20 min at 10°C. The material in the centrifuge tube is divided into two layers. The upper layer was the slurry part, which was discarded. The sediment at the bottom is collected as egg yolk particles. Wash three times with 0.16M NaCl solution, and centrifuge again under the same conditions. The granules were freeze-dried for later use.

[0044] 2. Take the egg yolk granules, add distilled water of equal quality, heat in a water bath at 65°C for 2 hours, remove the upper layer of floating matter (low-density lipoprotein), and obtain the lower layer of sediment, f...

Embodiment 2

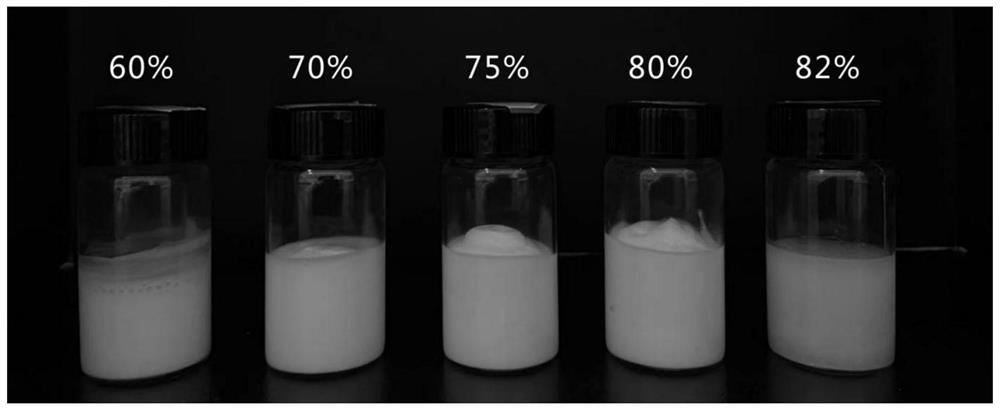

[0062] 60%: get the high-density lipoprotein particle 1g that embodiment 1 prepares, NaCl 0.05g, 4ml water are mixed, obtain mixed solution, adjust the pH of described mixed solution to 3~4, homogenize, obtain water phase; The aqueous phase was mixed with 6ml of vegetable oil and homogenized to obtain a high internal phase Pickering emulsion. The picture of the appearance after being placed for a day can be found in figure 2 .

[0063] 70%: get the high-density lipoprotein particle 1g that embodiment 1 prepares, NaCl 0.05g, 3ml water are mixed, obtain mixed solution, adjust the pH of described mixed solution to 3~4, homogenize, obtain water phase; The aqueous phase was mixed with 7ml vegetable oil and homogenized to obtain a high internal phase Pickering emulsion. The picture of the appearance after being placed for a day can be found in figure 2 .

[0064] 75%: get the high-density lipoprotein particle 1g that embodiment 1 prepares, NaCl 0.05g, 2.5ml water are mixed, ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com