Cleaning device for vertical axial flow harvester

A technology of cleaning device and harvester, which is applied to agricultural machinery and tools, threshing equipment, agriculture, etc. It can solve the problems of inability to minimize the loss rate of cleaning and impurity content, and inability to quickly adjust the screening angle and screen aperture, Woven sieve is not easy to replace and other problems, to achieve the effect of improving efficiency, reducing cleaning load, reducing loss rate and impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

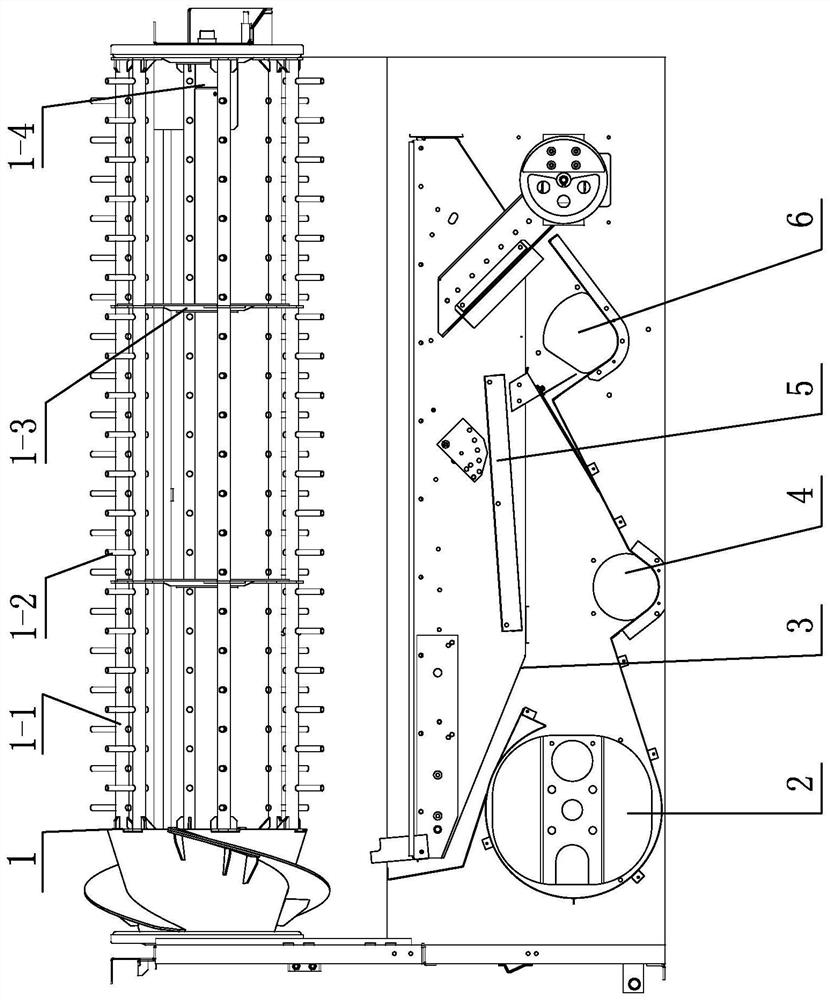

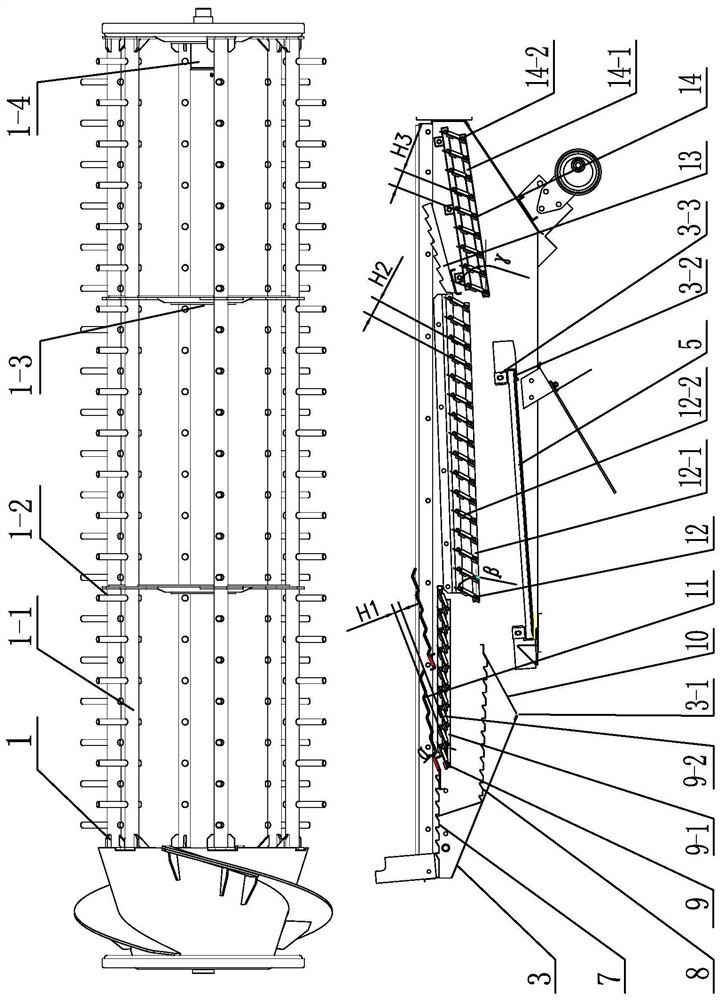

[0012] See figure 1 , 2 As shown, the cleaning device of a longitudinal axial flow harvester of the present invention includes a vibrating screening box 3 arranged at the lower part of the axial flow drum 1, and the axial flow drum 1 includes a tapered feeding part at the front end and a plurality of threshing rods 1 -1 is connected with a plurality of drum side plates 1-3 to form the cylinder body, and each threshing rod 1-1 is provided with a plurality of threshing gear rods 1-2, and the drum shaft 1-4 is connected with the drum side plates 1-3 and the cone Shaped connection, the drum shaft 1-4 is connected with the power to drive the axial flow drum 1 to rotate, and the three threshing areas of the front, middle and rear of the threshing section perform threshing on the fed grain and straw, and prevent the straw from being hit. Too broken. The upper part of the vibration screening box 3 is open, and the threshed grains and branches and leaves are cleaned. The front bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com