Small breeding sheller

A hulling machine, a small technology, applied in threshing equipment, seed and rhizome treatment, agricultural machinery and implements, etc. The problems of poor variety adaptability, to achieve the effect of facilitating cleaning and adjusting the shelling gap, improving the quality of shelling operations, and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

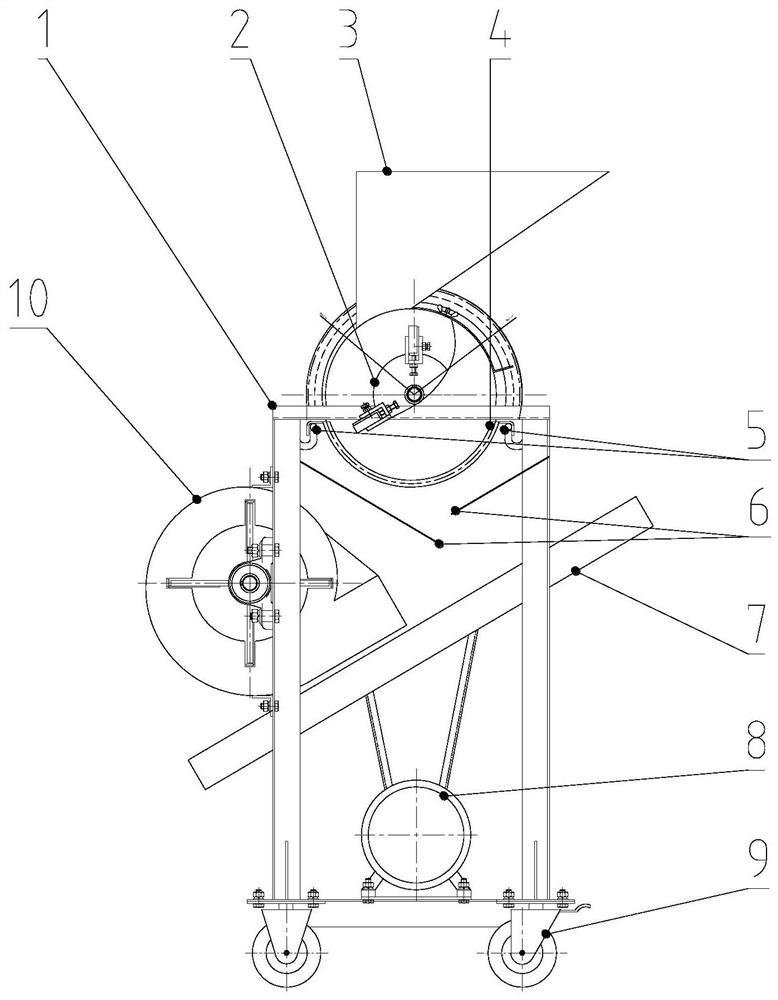

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

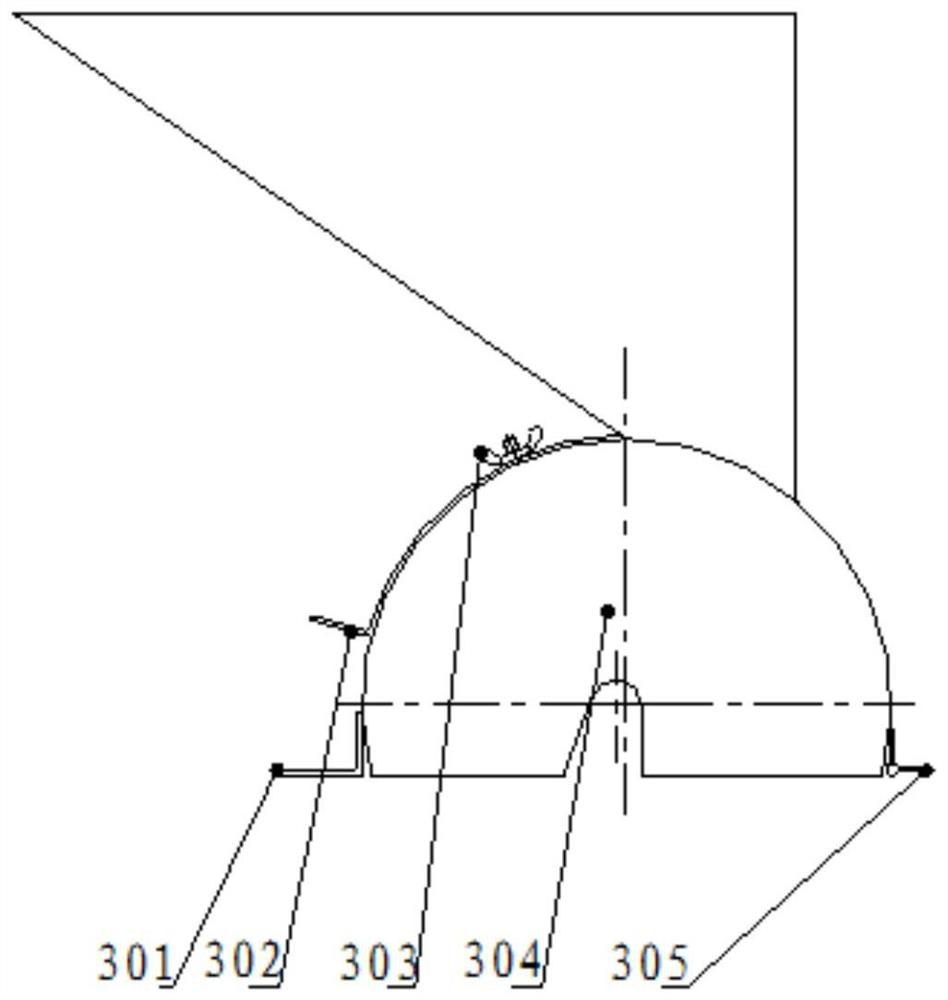

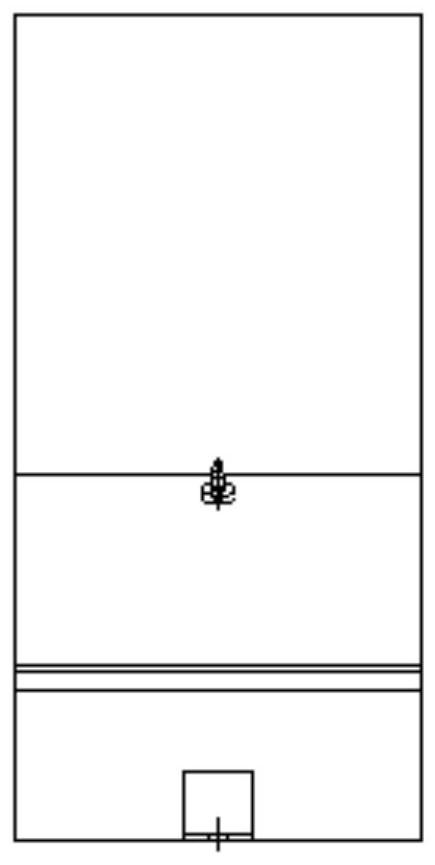

[0039] see Figure 1-Figure 13 , a small-sized breeding shelling machine, comprising a shelling drum 2, a sieve body 4, a feeding device 3, a U-shaped guide rail 5, and a guide rod 11; the shelling drum 2 has a shelling rotating part 201, and the shelling drum 2 The shell rotating part 201 includes a shelling disc 201b and several plate U-shaped supports 201a fixed in the radial direction at equal angles around it, and an L-shaped support plate 203 is arranged inside the plate U-shaped support 201a. Support plate 203 is positioned at the length of an end in the U-shaped groove width of beating plate U-shaped support 201a less than described U-shaped groove width; Described L-shaped support plate 203 and U-shaped support 201a clamp a rubber flexible beating plate 202; Adjust Bolt 204 passes U-shaped support 201a bottom surface against described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com