Automatic stripping device and automatic stripping method for outer protective sleeve of power cable

A power cable, automatic stripping technology, applied in the direction of cable installation device, cable installation, dismantling/armoured cable equipment, etc., can solve the problems of poor stripping quality, time-consuming, labor-intensive and labor-intensive, etc., achieve high regularity and reduce damage , Realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

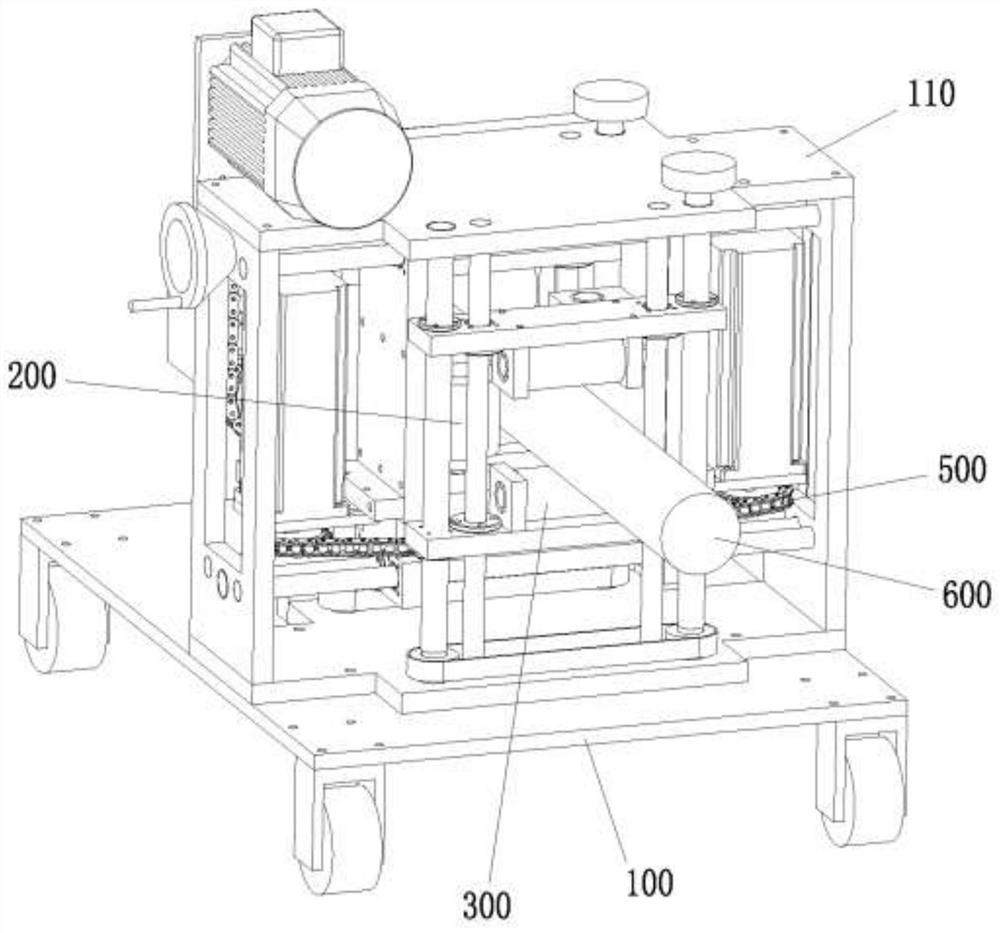

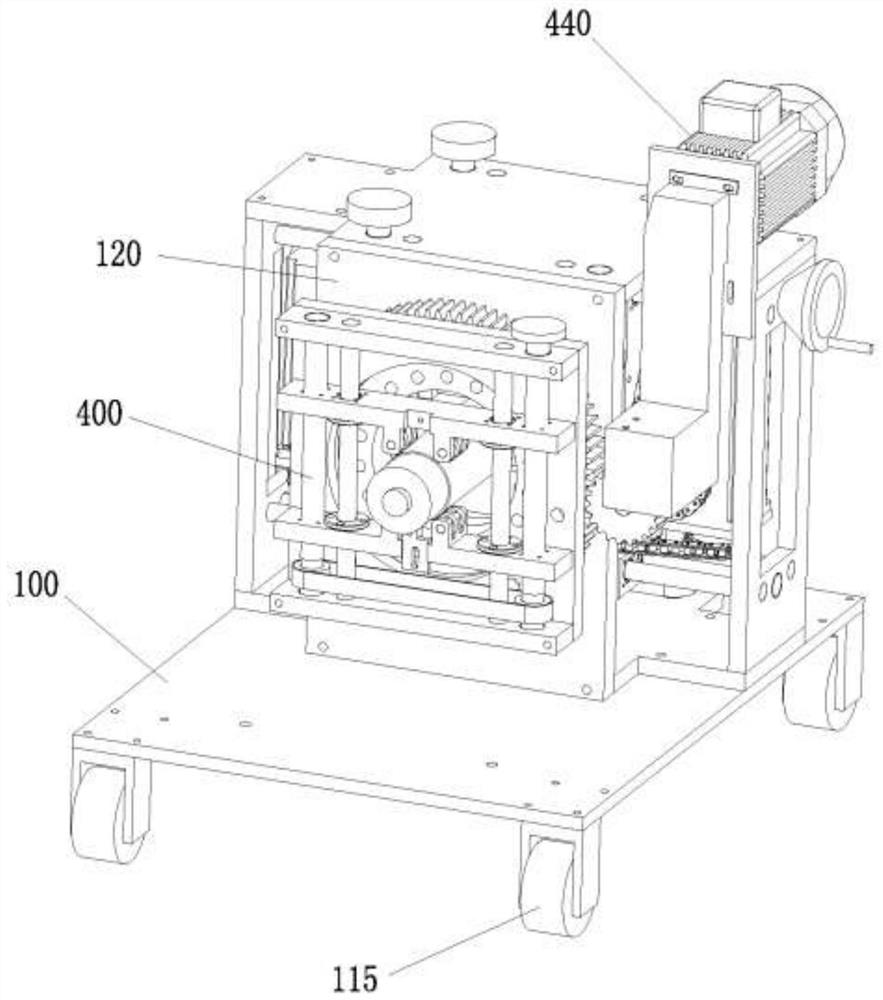

[0059] This embodiment provides a device for automatically stripping the outer protective sheath of a power cable, such as Figure 1-9 As shown, it includes a workbench 100, a feeding mechanism 200, a crimping mechanism 300 and a rotary peeling mechanism 400;

[0060] The workbench 100 comprises a support frame 110 and a fixed plate 120, the support frame 110 at least comprises a first plate 111, a second plate 112, a third plate 113 and a fourth plate 114, the first plate 111, the second plate 112, the third plate 113 and the fourth plate 114 are respectively connected to form a feed space 130, and the fixed plate 120 is located on the outlet side of the feed space 130;

[0061] The workbench 100 also preferably has a plurality of universal wheels 115 to quickly change the position, and the universal wheels 115 further have a self-locking function.

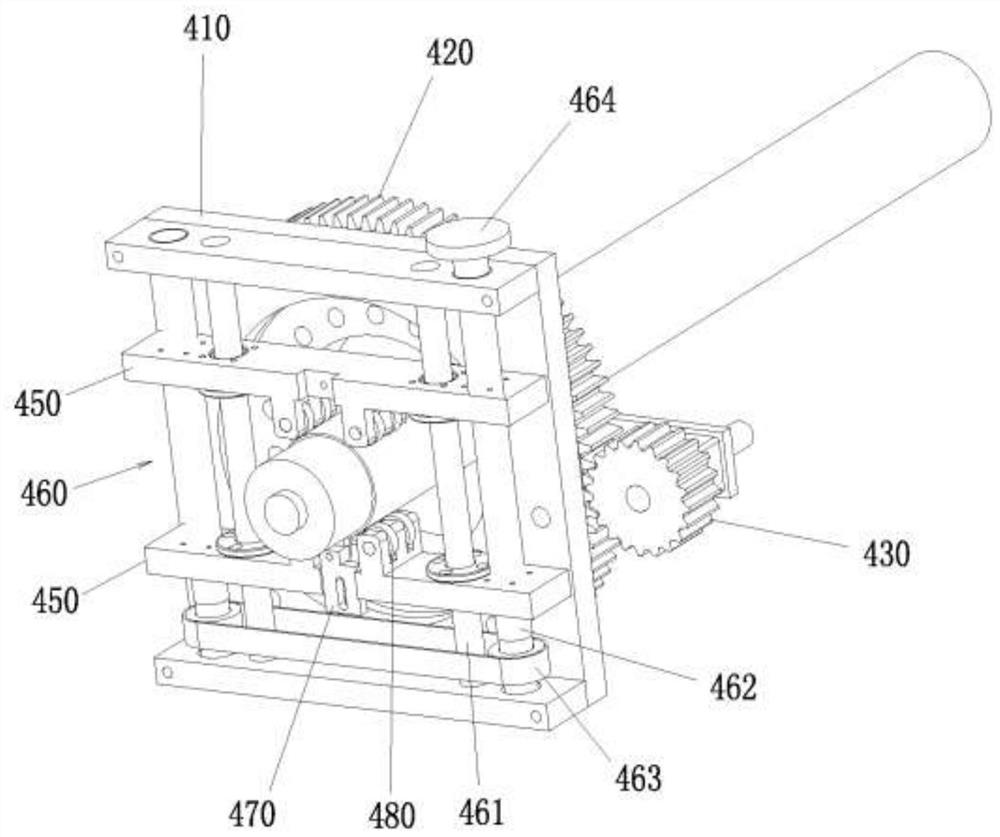

[0062] Such as Figure 3-4 As shown, the rotary peeling mechanism 400 is located on the fixed plate 120, and it includes a ro...

Embodiment 2

[0084] This embodiment provides a method for automatically stripping the outer protective sheath of a power cable, which can be realized by the automatic stripping device in Example 1, providing a support frame and having a feeding space for the power cable to pass through on the support frame, and providing a rotating frame And the rotary frame can rotate by itself, and a scraper is arranged on the rotary frame; the automatic stripping method comprises the following steps:

[0085] Crimping of power cables:

[0086] There are two sets of crimping rollers facing each other at the entrance and exit of the feeding space. The two sets of crimping rollers are located on the upper and lower sides of the power cable. The two sets of crimping rollers are driven up and down by the first screw guide assembly. Close to or separate from the back to compress the power cable, and keep the center of the power cable coincident with the center of rotation of the rotating frame;

[0087] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com