Visual quality detection method and system for industrial production

A quality detection method and target detection technology, applied in the field of visual quality detection in industrial production, can solve the problems of inconvenient detection, inconvenient readers, easy loss of drawings and measurement results, etc., to achieve fast and accurate identification, solve the inconvenience of viewing and operation, Effects that are easy to see and manipulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

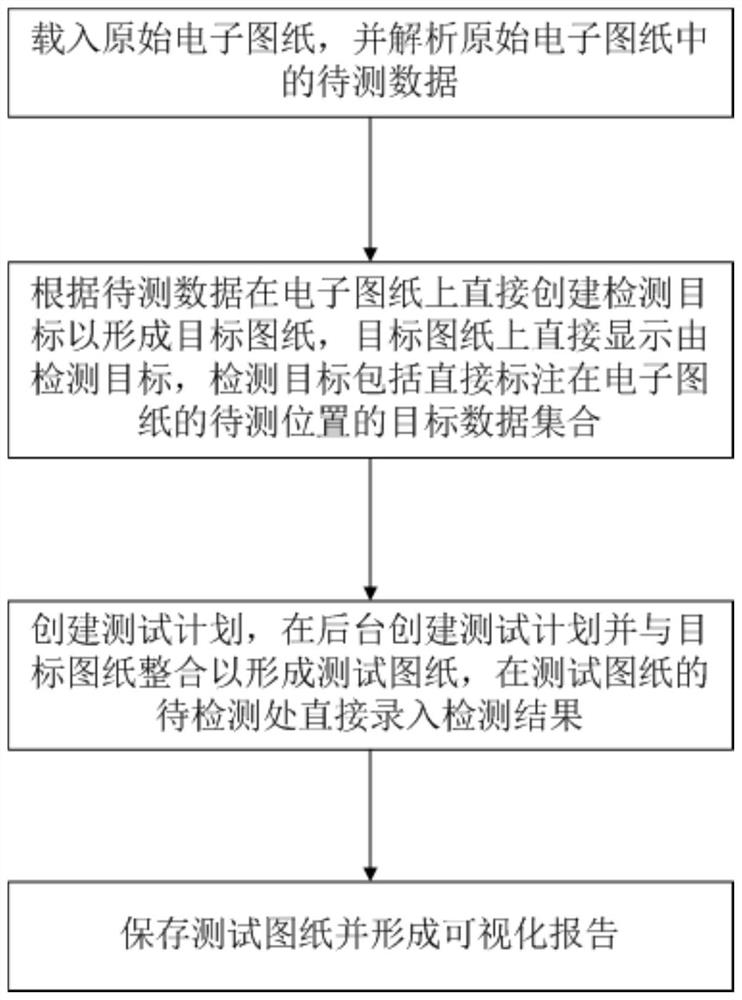

[0023] See attached figure 1 Shown, a kind of visual quality inspection method for industrial production of the present invention comprises the following steps:

[0024] Step 1. Load the original electronic drawing and analyze the data to be measured in the original electronic drawing.

[0025] The original electronic drawings in the step 1 are in picture format, and the original electronic drawings in picture format are converted from CAD drawings, on which schematic diagrams of various angles of the product are drawn.

[0026] Step 2. Create a detection target directly on the electronic drawing according to the data to be tested to form a target drawing. The detection target is directly displayed on the target drawing, and the detection target includes the target data set directly marked on the electronic drawing at the position to be measured.

[0027] The target data set in step 2 includes at least one preset detection rule, and the preset detection rule includes a target...

Embodiment 2

[0037] The invention also provides a visual quality detection system for industrial production, the detection results are easy to identify and determine, no need to print drawings and record sheets, automatic production can be realized, and production efficiency can be improved. The system includes a data processing module, and the data processing module is configured with a computer program. When the computer program is executed, the above-mentioned visual quality detection method for industrial production is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com