A method for non-directional screening of flavors, fragrances and their derivatives in food based on characteristic fragments of gas mass spectrometry

A flavor, fragrance, and non-directional technology, which is applied in the field of non-directional screening of flavors, fragrances and their derivatives in food based on gas mass spectrometry characteristic fragments, can solve the problems of inaccurate results, increased errors, unknown structures of unknown compounds, etc., and achieves scientific results. Accuracy, low detection cost, and wide screening range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

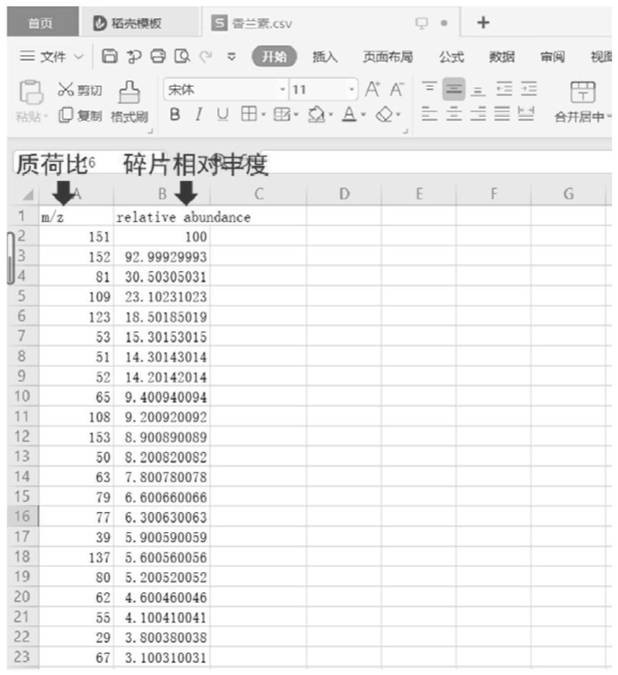

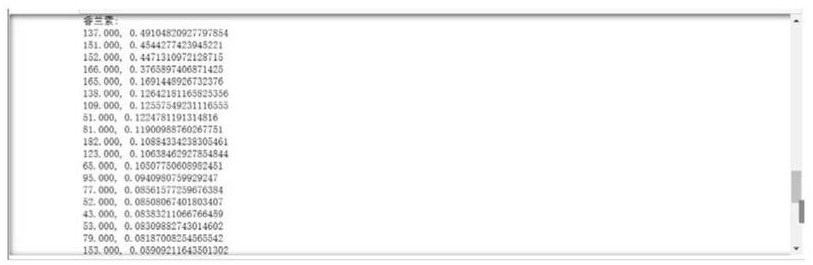

[0055] Qualitative screening of vanillin in embodiment 1 liquid milk

[0056] 1. Detection of samples to be tested

[0057] Liquid milk: Accurately weigh 5.0 g of liquid milk sample into a 15 mL headspace bottle, add 100 μL of 5 mg / L vanillin compound standard mixture, shake and mix evenly. Add 3g of sodium chloride for GC-Q-TOF determination to obtain the full scan spectrum and data of the sample to be tested.

[0058] Instrument parameter setting:

[0059] Solid phase microextraction conditions: oscillator preheating temperature: 70°C; rotating speed: 500r / min; preheating time: 20min; extraction time: 25min; desorption time: 5min.

[0060] Chromatographic conditions: gas chromatographic column is DB-5MS (30m×0.25mm×0.25μm); temperature program heating process: keep at 80°C for 2min, raise the temperature to 150°C at 10°C / min, keep it for 5min, then raise the temperature to 150°C at 20°C / min 280°C, hold for 3.5min; carrier gas: helium, purity ≥99.999%, flow rate 1.5mL / min;...

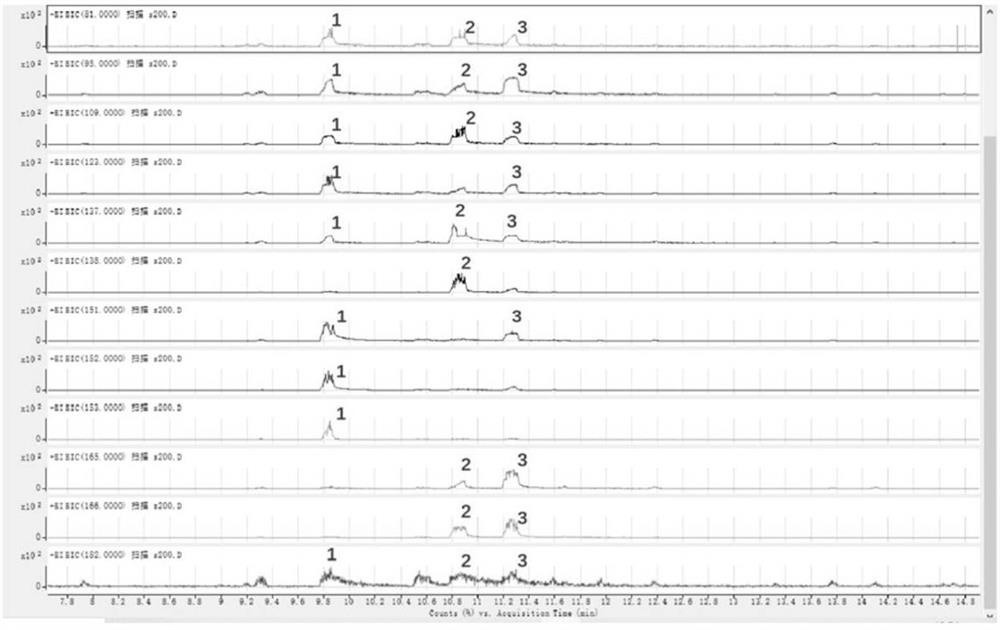

Embodiment 2

[0075] Semi-quantitative detection of embodiment 2 vanillin compounds

[0076] 1. Detection of semi-quantitative samples

[0077] Semi-quantitative milk powder sample preparation: Weigh 5.0g of milk powder, add 45mL of water to prepare, weigh 5.0g into a 15mL headspace bottle, add 100μL of 5mg / L vanillin compounds mixed standard, shake and mix well . Add 3g of sodium chloride for GC-Q-TOF determination to obtain the full scan spectrum and data of the sample to be tested.

[0078] Instrument parameter setting:

[0079] Solid phase microextraction conditions: oscillator preheating temperature: 70°C; rotating speed: 500r / min; preheating time: 20min; extraction time: 25min; desorption time: 5min.

[0080] Chromatographic conditions: gas chromatographic column is DB-5MS (30m×0.25mm×0.25μm); temperature program heating process: keep at 80°C for 2min, raise the temperature to 150°C at 10°C / min, keep it for 5min, then raise the temperature to 150°C at 20°C / min 280°C, hold for 3.5m...

Embodiment 3

[0113] Example 3: Semi-quantitative homologues of vanillin

[0114] 1. Detection of semi-quantitative samples

[0115] Semi-quantitative milk powder sample preparation: Weigh 5.0g of milk powder, add 45mL of water to prepare, weigh 5.0g into a 15mL headspace bottle, add 100μL of 5mg / L methyl vanillin and ethyl vanillin compounds Mix the standards and vortex to mix well. Add 3g of sodium chloride for GC-Q-TOF determination to obtain the full scan spectrum and data of the sample to be tested.

[0116] Instrument parameter setting:

[0117] Solid phase microextraction conditions: oscillator preheating temperature: 70°C; rotating speed: 500r / min; preheating time: 20min; extraction time: 25min; desorption time: 5min.

[0118] Chromatographic conditions: gas chromatographic column is DB-5MS (30m×0.25mm×0.25μm); temperature program heating process: keep at 80°C for 2min, raise the temperature to 150°C at 10°C / min, keep it for 5min, then raise the temperature to 150°C at 20°C / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com