Oil gas recovery break-away valve

A breakaway valve, oil and gas technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of unsealed gas passages, short service life of oil and gas recovery breakaway valves, and high maintenance costs, so as to prevent oil leakage and reduce costs. Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

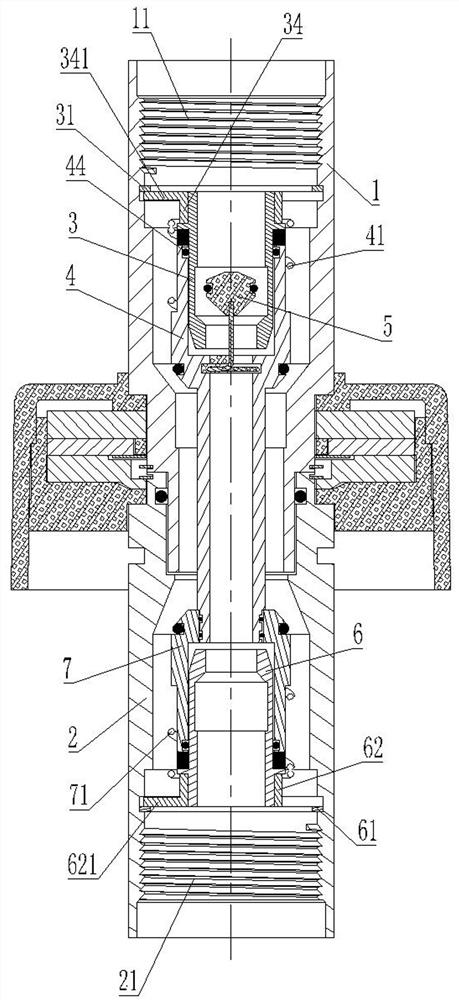

[0031] Embodiment 1: An oil and gas recovery break-off valve, its structure please refer to Figure 3 to Figure 6 .

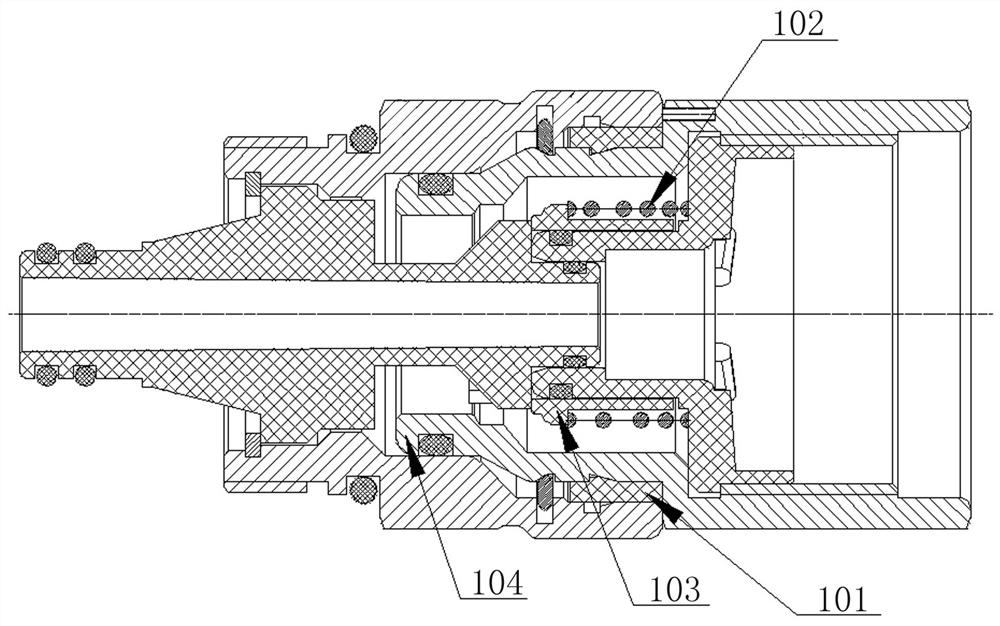

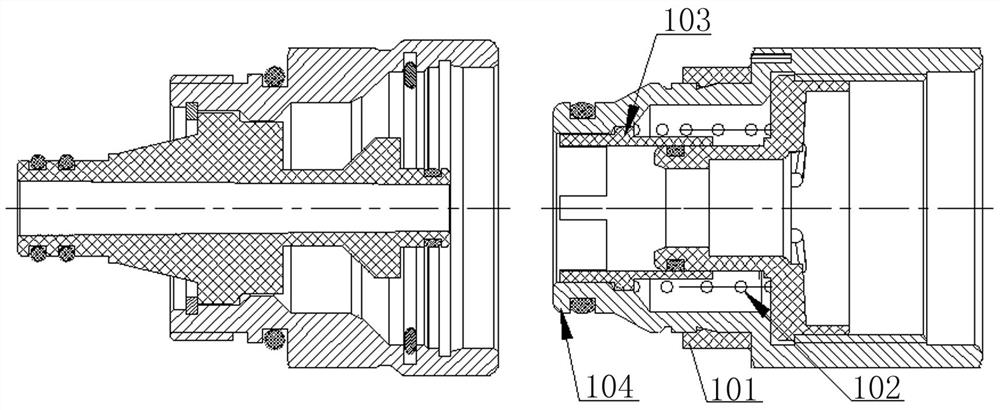

[0032] Such as image 3 As shown, the oil and gas recovery pull-off valve in this embodiment is divided into upper and lower halves, the upper half includes the first valve body 1, the lower half includes the second valve body 2, the first valve body 1 and the second valve body 2 are both Hollow, the top of the first valve body 1 is provided with a first threaded port 11 for connecting pipes, and the bottom of the second valve body 2 is provided with a second threaded port 21 for connecting pipes. Figure 4 and Figure 5 As shown, the lower port 12 of the first valve body 1 is used to be plugged into the upper port 22 of the second valve body 2, so that the first valve body 1 and the second valve body 2 can be docked with each other, and the second valve body 2 The inner wall of the upper port 22 is provided with a fifth sealing ring 221 for closing the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com