A new type of suction muffler for refrigerator compressor

A refrigerator compressor and muffler technology, which is applied in the direction of machines/engines, mechanical equipment, liquid displacement machinery, etc., can solve the problems of reduced air flow of the muffler, occupying the muffler, and affecting the performance of the compressor, so as to achieve good noise reduction and noise reduction. Ease of installation without compromising performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

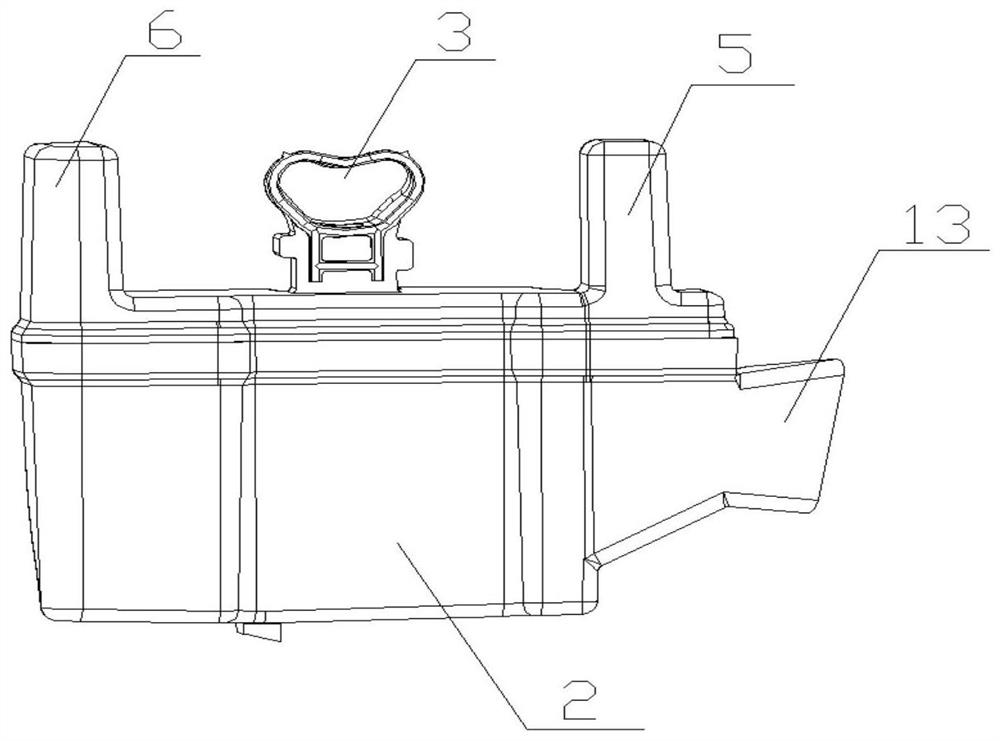

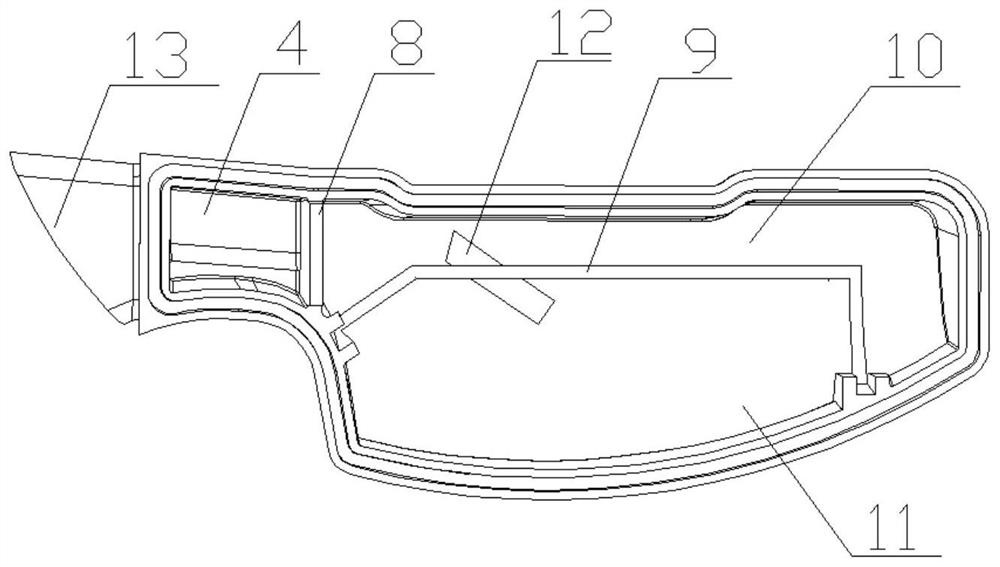

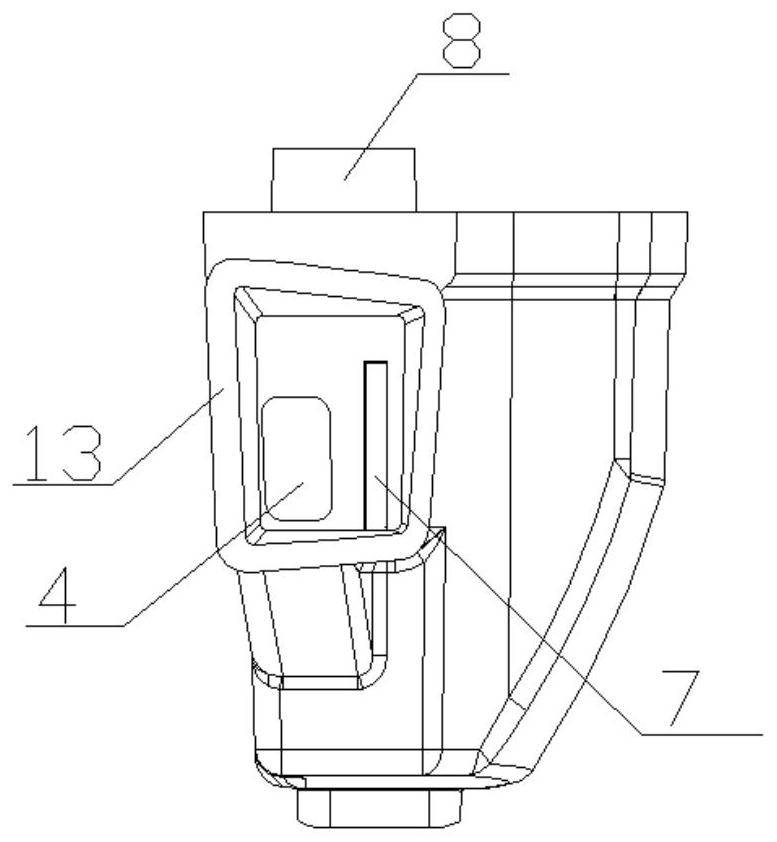

[0028] This embodiment provides a new type of suction muffler for a refrigerator compressor, as attached Figure 1-3 As shown, the muffler chamber includes an upper chamber 1 and a lower chamber 2, and the upper chamber 1 and the lower chamber 2 are connected and communicated through a slot. The upper chamber 1 is provided with an air outlet pipe 3, and one side of the lower chamber 1 is arranged side by side with an air inlet pipe 1 4 and an air inlet pipe 2 7, which can simultaneously take in air. In rubber sleeve 13, wherein the length of air intake pipe one 4 air inlet is 3mm, and the width is 2.5mm; And the length 4.5mm of air intake pipe two 7 air inlets, wide is 1.5mm. The outlet of the intake pipe one 4 is provided with a partition one 8, and the middle of the lower chamber 2 is provided with a partition two 9, and the partition two 9 divides the lower chamber 2 into an expansion chamber one 10 and an expansion chamber two 11, and the expansion chamber one 10 communic...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 lies in that the noise cancellation frequency of the first Helmholtz resonance cavity 5 is 600 Hz, and the noise cancellation frequency of the second Helmholtz resonance cavity 6 is 1000 Hz.

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 lies in that the noise cancellation frequency of the first Helmholtz resonance cavity 5 is 800 Hz, and the noise cancellation frequency of the second Helmholtz resonance cavity 6 is 1300 Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com