Control method and device of engine

A control method and control device technology, which is applied in engine control, machine/engine, electrical control, etc., can solve the problems such as tail NOx cannot be controlled within the original level range, urea cannot fully react, and ammonia leakage exceeds the standard, etc., to achieve reduction The effect of controlling difficulty, avoiding wrong direction of correction, and preventing excessive emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention.

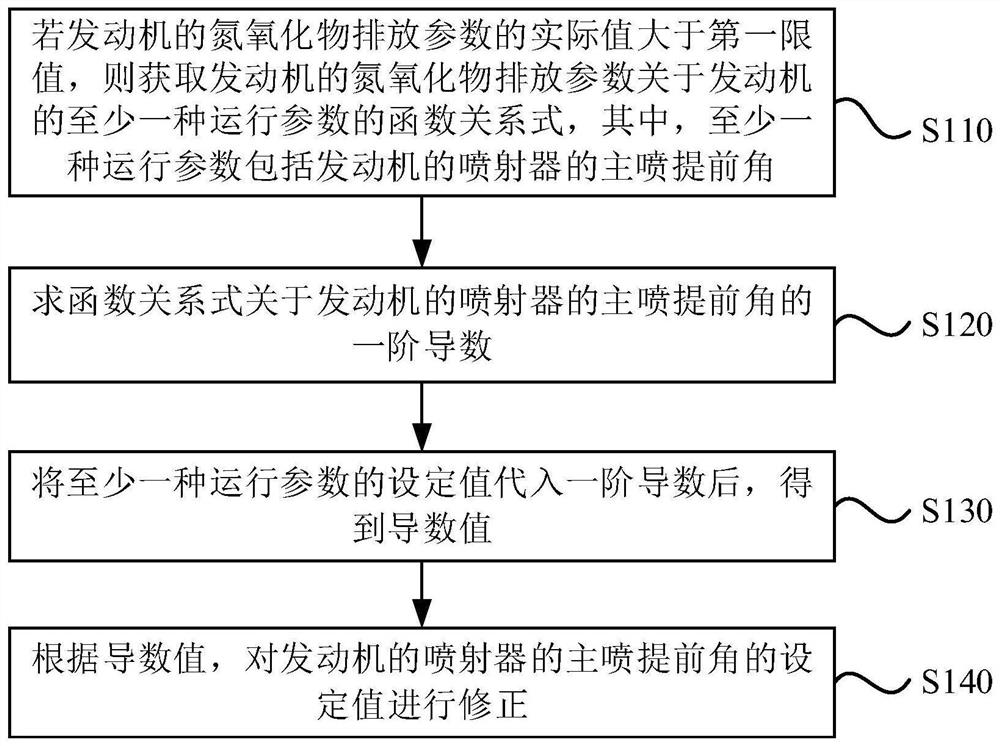

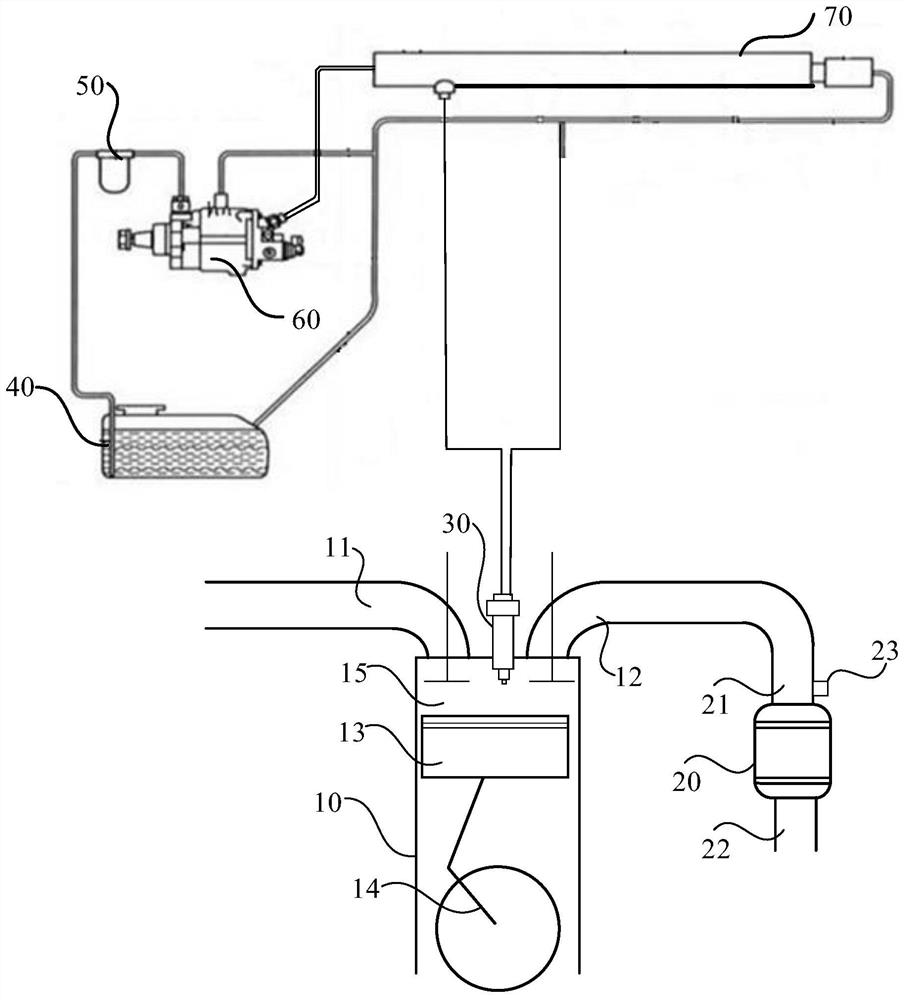

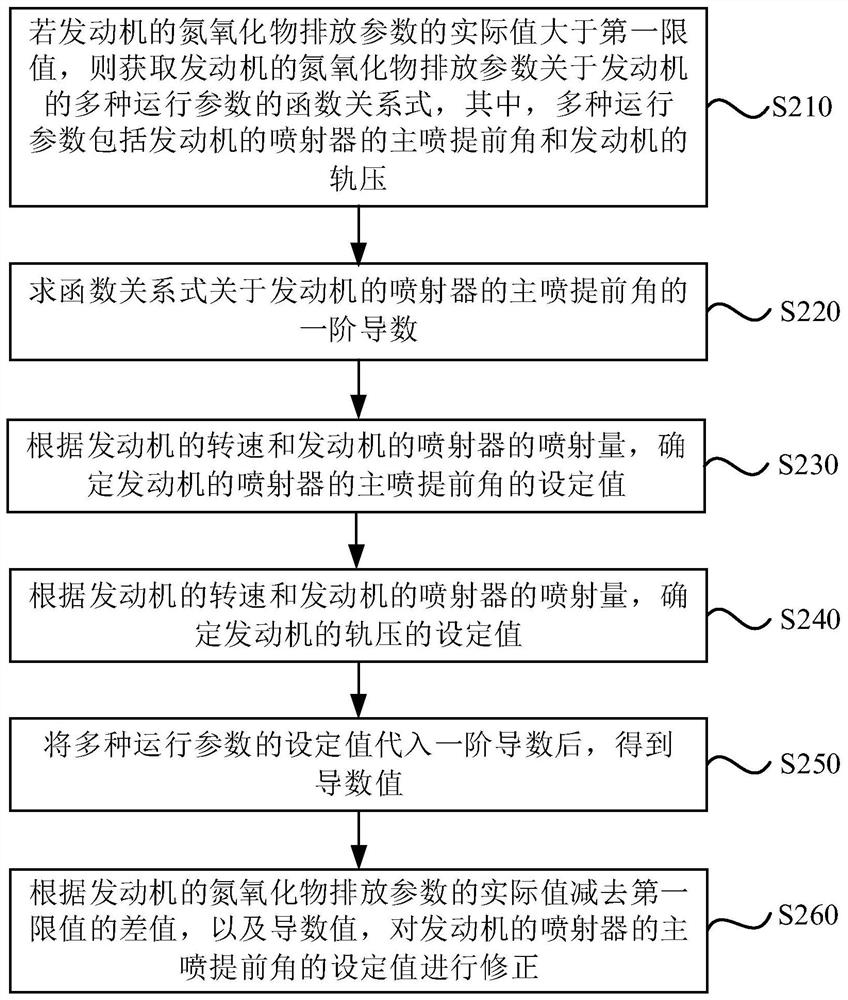

[0045] Embodiments of the present invention provide an engine control method. figure 1 A flowchart of an engine control method provided by an embodiment of the present invention. figure 2 A schematic structural diagram of an engine provided by an embodiment of the present invention. The method may be executed by a control device of the engine, the device may be implemented by software and / or hardware, and the device may be integrated in an electronic control unit (Electronic Control Unit, ECU) of the engine. The method specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com