Longitudinal rubber cutting machine

A cutting machine and vertical technology, applied in metal processing and other directions, can solve the problems of shortening the service life of saw blades, reducing rubber performance, affecting work efficiency, etc., achieving good cooling effects, avoiding smoke, and convenient and flexible adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

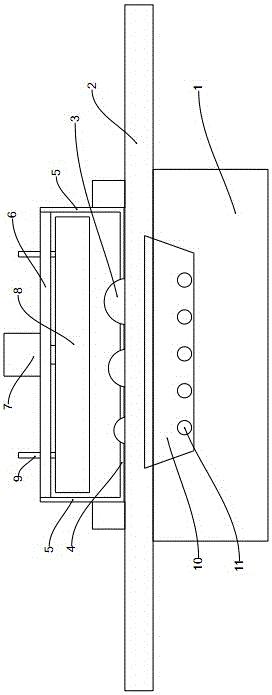

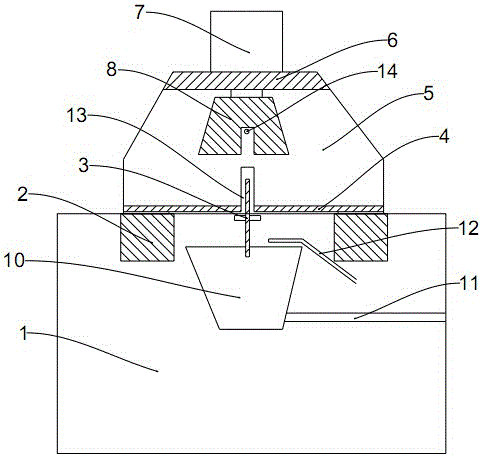

[0021] Such as figure 1 , figure 2 As shown, a rubber longitudinal cutting machine described in this embodiment includes a frame 1 and a power source, two slide rails 2 parallel to each other are arranged on the frame 1, and a horizontal working platform is set on the slide rail 2 4. There are side walls 5 on both sides of the working platform 4, a cross arm 6 is set above the side wall 5, and a pressing block 8 is set above the working platform 4. The pressing block 8 passes through the vertical between the guide rod 9 and the cross arm 6. Sliding connection in the vertical direction, a vertically downward cylinder 7 is arranged on the cross arm 6, and the telescopic end of the cylinder 7 is fixedly connected with the pressing block 8; three circular cylinders are arranged in sequence along the direction of the slide rail 2 on the frame 1 Saw blades 3, the height of one circular saw blade 3 exposed on the working platform 4 is 30 mm, the height of one circular saw blade 3 e...

Embodiment 2

[0026] A kind of rubber longitudinal cutting machine described in this embodiment, it comprises frame 1 and power source, is provided with two slide rails 2 parallel to each other on frame 1, is provided with horizontal working platform 4 on slide rail 2, works Side walls 5 are arranged on both sides of the platform 4, a cross arm 6 is arranged above the side wall 5, and a pressing block 8 is arranged above the working platform 4, and the pressing block 8 slides vertically between the guide rod 9 and the cross arm 6 connection, a vertically downward cylinder 7 is set on the cross arm 6, and the telescopic end of the cylinder 7 is fixedly connected with the pressing block 8; three circular saw blades 3 are arranged in sequence along the direction of the slide rail 2 on the frame 1 , the height of one circular saw blade 3 exposed on the working platform 4 is 30 mm, the height of one circular saw blade 3 exposed on the working platform 4 is 60 mm, and the height of one circular sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com