Floor slab, bidirectional stiffening rigid part and flange plate overhanging web shear type replaceable energy-consuming beam section laminated connection combined joint

A technology of combining joints and flange plates, which is applied to building components, building types, earthquake resistance, etc., can solve problems such as increased cost of structure demolition and repair, concrete shedding, overall collapse, etc., and achieves convenient design, weak shear stiffness, and lightening damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

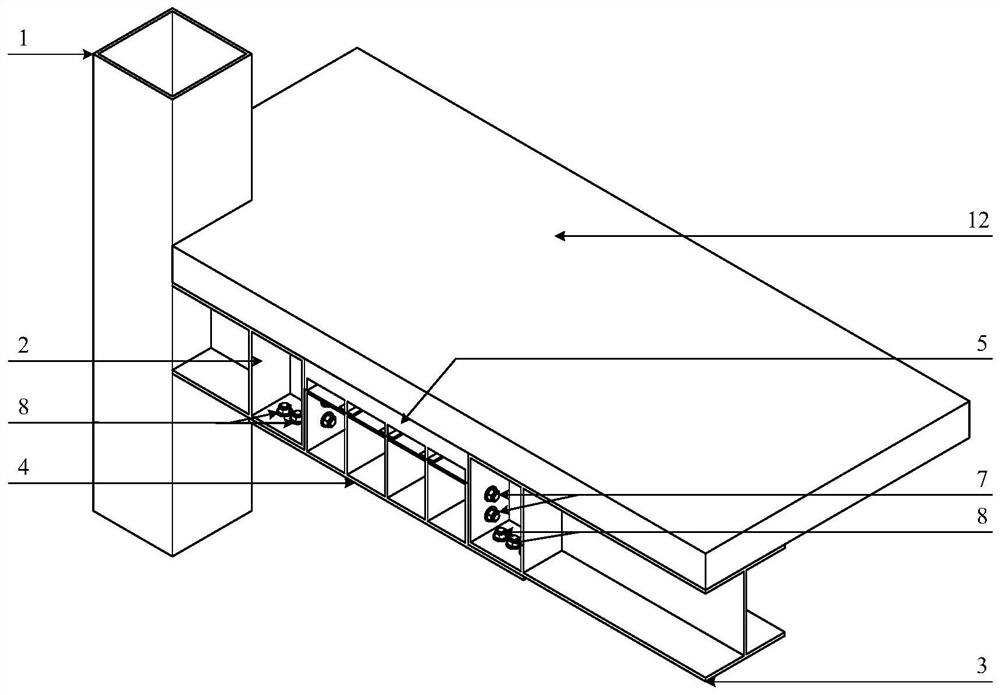

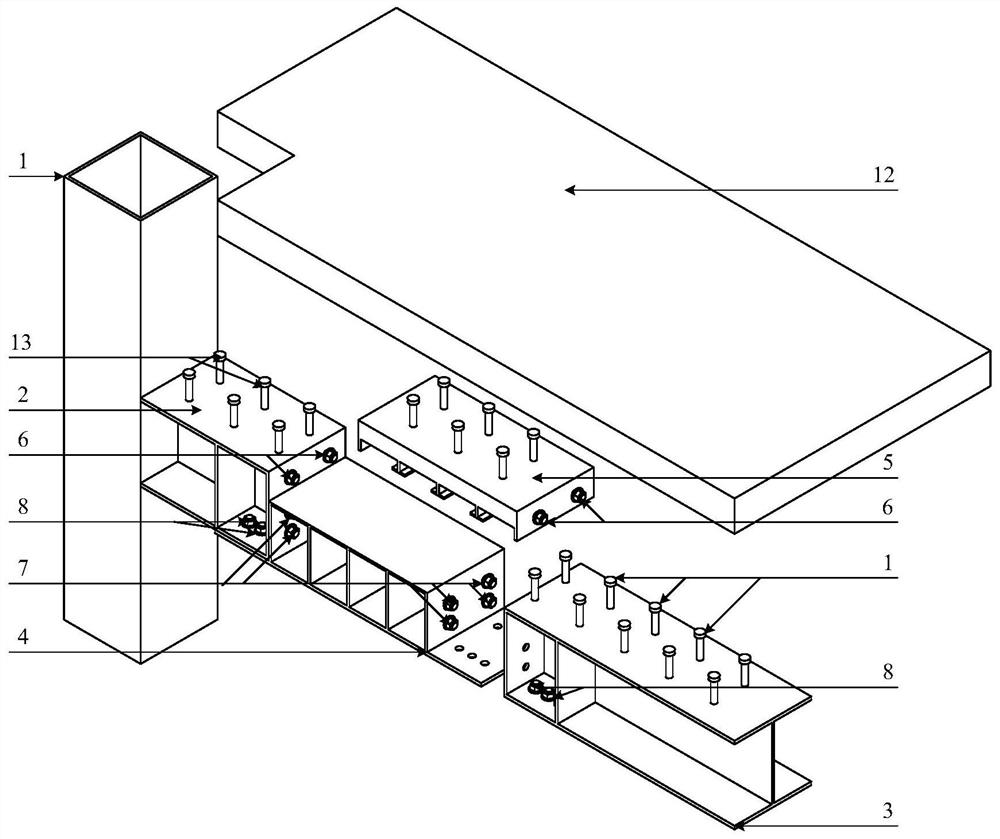

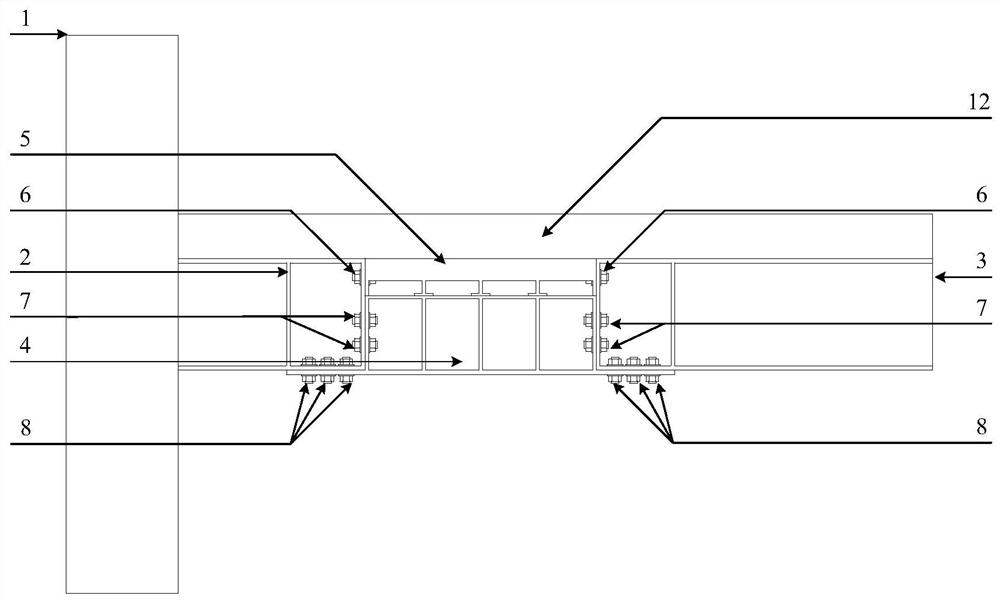

[0018] Attached below Figure 1~5 , detailing the implementation of this patent.

[0019] Such as Figure 1~5 As shown, a composite joint of floor slab, two-way stiffening rigid member and flange plate with extended web shear type replaceable energy-dissipating beam segment laminated connection includes the following components:

[0020] 1——square steel column

[0021] 2 - cantilever beam section

[0022] 3——Middle beam section

[0023] 4——External web shearing type replaceable energy-dissipating beam section of flange plate

[0024] 5——Two-way stiffening rigid parts

[0025] 6——The first high-strength bolt group

[0026] 7——The second high-strength bolt group

[0027] 8——The third high-strength bolt group

[0028] 9——transverse stiffener

[0029] 10——Longitudinal stiffener

[0030] 11——Pallet

[0031] 12 - concrete floor

[0032] 13 - pegs

[0033] 14——The lower flange plate of energy-dissipating beam section can be replaced

[0034] 15——The upper flange plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com