Floor tile mounting machine capable of preventing damage and rapidly mounting floor tiles

An anti-damage and installation machine technology, applied in construction, building structure, etc., can solve the problems of poor decoration quality, loose fitting, damaged connection of floor tiles, etc., and achieve the effect of improving decoration quality and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

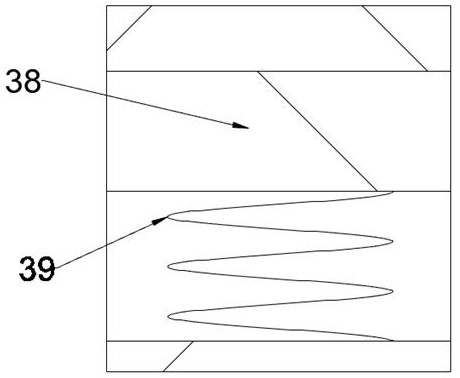

[0033] Embodiment 1, the supporting device 102 includes a supporting spring 39 uniformly and fixedly arranged on the lower cavity wall of the placement chamber 12 , and a supporting plate 38 is fixedly fixed on the upper end surface of the supporting spring 39 .

Embodiment 2

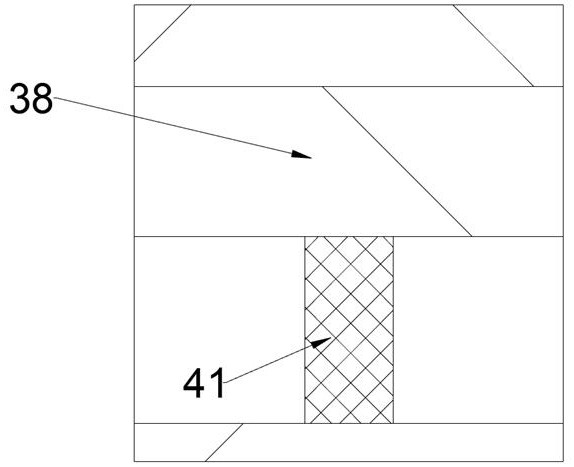

[0034] Embodiment 2, the support device 102 includes a support rod 41 uniformly fixed on the lower cavity wall of the placement cavity 12 , and a support plate 38 is fixedly fixed on the upper end surface of the support spring 39 .

[0035] Concrete method of use of the present invention is:

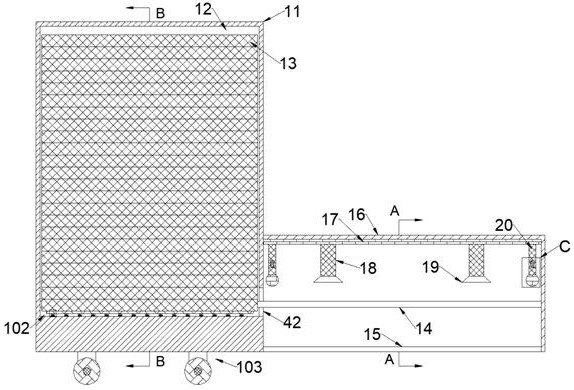

[0036] When floor tiles are installed, the cement slurry is injected into the storage tank 22 through the feed port 23, and the clamping cylinder 31 is activated to push the clamping piston rod 32 so that the rotating motor 30 pushes the clamping plate 34 to move towards the direction of mutual approach to move the floor tiles 13 Clamping, the moving slide rail 14 starts to move the floor tile 13 to the right through the clamping plate 34, and enters the working box 16 through the opening 42,

[0037] Embodiment 1: After the moving slide rail 14 drives the floor tiles 13 to move, the upper floor tiles 13 move downward under the action of gravity and continue to be stacked on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com